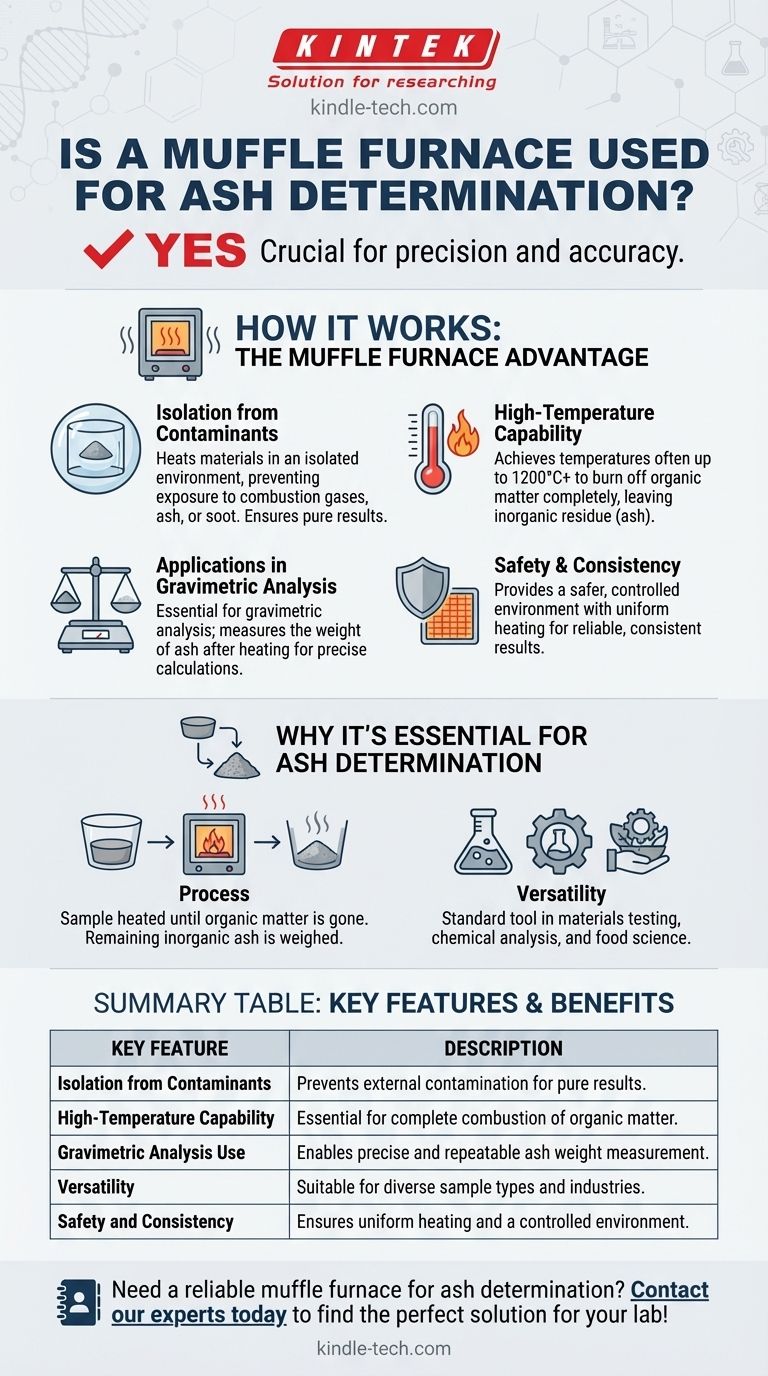

Yes, a muffle furnace is used for ash determination. This is because it provides a controlled, high-temperature environment that ensures materials are heated without contamination from combustion gases or residues. The muffle furnace's ability to isolate the material being heated makes it ideal for processes like ash determination, where purity and accuracy are critical. Below is a detailed explanation of how and why muffle furnaces are used for this purpose.

Key Points Explained:

-

Isolation from Contaminants:

- A muffle furnace is designed to heat materials in an isolated environment, preventing contamination from combustion gases, ash, or soot. This is crucial for ash determination, as any external contaminants could skew the results.

- The muffle (heat-resistant inner container) ensures that the material being tested is heated uniformly and without exposure to impurities.

-

High-Temperature Capability:

- Ash determination requires heating materials to very high temperatures to burn off organic matter and leave behind inorganic residues (ash). Muffle furnaces can achieve the necessary temperatures (often up to 1200°C or higher) for this process.

- The furnace's ability to maintain consistent high temperatures ensures complete combustion of organic materials, which is essential for accurate ash content measurement.

-

Applications in Gravimetric Analysis:

- Ash determination is a form of gravimetric analysis, where the weight of the residue (ash) is measured after heating. Muffle furnaces are commonly used in gravimetric analysis because they provide precise and repeatable heating conditions.

- The isolation from external contaminants ensures that the ash residue is pure and representative of the material being tested.

-

Versatility in Scientific and Industrial Settings:

- Muffle furnaces are widely used in laboratories and industries for various high-temperature applications, including ash determination. Their versatility makes them a standard tool in fields like materials testing, chemical analysis, and food science.

- The ability to handle different sample sizes and types further enhances their suitability for ash determination.

-

Safety and Consistency:

- Muffle furnaces provide a safer working environment by isolating the heating process from external chemicals and substances. This is particularly important in ash determination, where the presence of contaminants could lead to inaccurate results or hazardous reactions.

- The uniform heating provided by muffle furnaces ensures consistent results, which is critical for reliable ash determination.

-

Specific Use in Ash Determination:

- In ash determination, the sample is placed in the muffle furnace and heated until all organic matter is burned off. The remaining inorganic residue (ash) is then weighed to determine its proportion in the original sample.

- The muffle furnace's design ensures that the sample is heated evenly and without interference from external factors, making it the preferred equipment for this process.

In summary, muffle furnaces are essential for ash determination due to their ability to provide a contaminant-free, high-temperature environment. Their design ensures accurate and consistent results, making them a critical tool in scientific research and industrial applications.

Summary Table:

| Key Feature | Description |

|---|---|

| Isolation from Contaminants | Prevents contamination from combustion gases, ensuring pure and accurate results. |

| High-Temperature Capability | Achieves temperatures up to 1200°C, essential for complete combustion of organic matter. |

| Applications in Gravimetric Analysis | Used for measuring ash residue weight with precision and repeatability. |

| Versatility | Suitable for various industries, including materials testing and food science. |

| Safety and Consistency | Provides uniform heating and a safer environment for accurate ash determination. |

Need a reliable muffle furnace for ash determination? Contact our experts today to find the perfect solution for your lab!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between muffle furnace and air oven? Choose the Right Tool for Your Thermal Process

- How is heat transferred in a furnace? Master Radiation, Convection & Conduction

- What is the difference between a muffle furnace and a normal furnace? Ensuring Sample Purity with Indirect Heating

- What is the burnout cycle on a furnace? Stop This Destructive Overheating Pattern Now

- What is melt loss? The Ultimate Guide to Reducing Metal Loss in High-Temp Processing