In short, yes. Physical Vapor Deposition (PVD) is generally considered an expensive, premium finishing process compared to traditional methods like painting, powder coating, or electroplating. The cost is not a simple number, however, as it reflects a highly technical process that fundamentally changes a material's surface properties on a molecular level, providing exceptional durability and performance.

The cost of PVD is not just for a "layer of color," but an investment in high-performance surface engineering. The final price is determined by specific variables like the coating material, part complexity, and required thickness, which directly correlate to the finish's ultimate longevity and function.

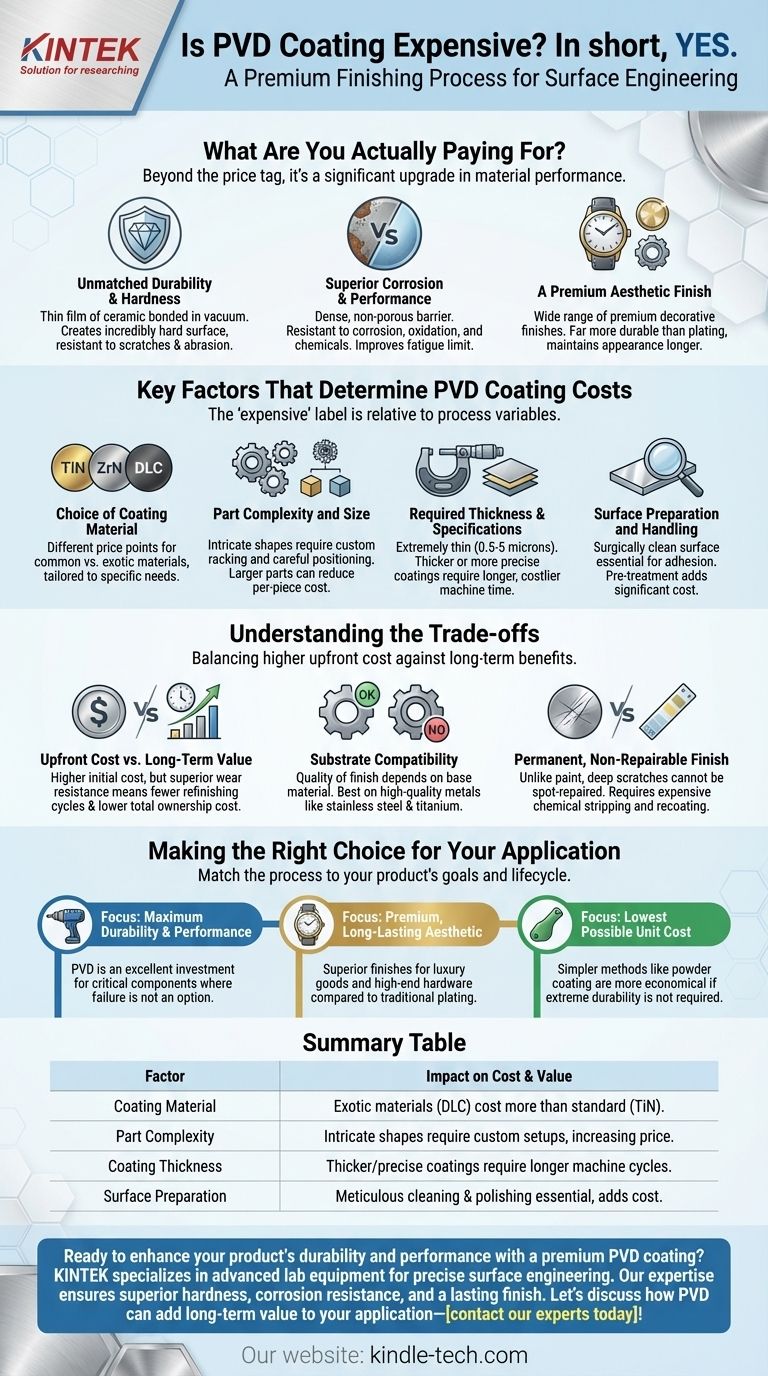

What Are You Actually Paying For?

Understanding the cost of PVD requires looking beyond the price tag to the inherent value it adds. You are paying for a significant upgrade in material performance.

Unmatched Durability and Hardness

PVD isn't a simple layer of paint; it's a thin film of ceramic material bonded to the substrate in a high-vacuum environment. This creates an incredibly hard surface that is highly resistant to scratches and abrasion.

The final hardness is a key factor in its durability, making it ideal for high-wear applications.

Superior Corrosion and Performance

The process creates a dense, non-porous barrier that is exceptionally resistant to corrosion, oxidation, and chemicals.

For specialized engineering applications, PVD coatings can dramatically improve performance. For example, applying a TiN coating to a titanium alloy can increase its fatigue limit and endurance, extending the life of critical components.

A Premium Aesthetic Finish

While highly functional, PVD is also used to achieve a wide range of premium decorative finishes on materials like stainless steel.

These coatings are far more durable than traditional plating, ensuring that products maintain their appearance for much longer.

Key Factors That Determine PVD Coating Costs

The "expensive" label is relative because the final price is a direct result of several critical process variables.

The Choice of Coating Material

The material being deposited has a significant impact on cost. Common materials like Titanium Nitride (TiN) have different price points than more specialized or exotic materials like Zirconium Nitride (ZrN) or Diamond-Like Carbon (DLC).

Each material offers different physical and chemical properties, tailored to specific needs.

Part Complexity and Size

The geometry of the parts being coated is a major cost driver. Complex shapes require custom racking and careful positioning within the vacuum chamber to ensure a uniform coating.

Larger parts or higher quantities can reduce the per-piece cost, but setting up for a specific job involves fixed expenses.

Required Thickness and Specifications

PVD coatings are extremely thin, typically ranging from 0.5 to 5 microns. A thicker or more precise coating requires a longer deposition cycle time inside the chamber.

Since machine time is a primary cost component, longer cycles directly translate to a higher price.

Surface Preparation and Handling

PVD requires a surgically clean surface for proper adhesion. The cost of pre-treatment—which can include cleaning, polishing, de-greasing, or sandblasting—is a significant part of the overall expense.

Any imperfections on the base material will be visible through the thin PVD coating, so meticulous preparation is non-negotiable.

Understanding the Trade-offs

Choosing PVD involves balancing its higher upfront cost against its long-term benefits and limitations.

Upfront Cost vs. Long-Term Value

PVD is almost always more expensive upfront than alternatives. However, its superior wear resistance means the part will not need to be refinished or replaced as often, potentially leading to a lower total cost of ownership over the product's lifespan.

Substrate Compatibility

The quality of the PVD finish is heavily dependent on the underlying material it's applied to. The process is best suited for high-quality metals like stainless steel, titanium, and certain alloys that can withstand the heat and vacuum conditions of the deposition chamber.

It's a Permanent, Non-Repairable Finish

Unlike paint that can be touched up, a deep scratch that penetrates the PVD coating cannot be spot-repaired. The entire part must be chemically stripped and completely recoated, which is an expensive and time-consuming process.

Making the Right Choice for Your Application

Ultimately, the decision to use PVD should be driven by your product's specific goals.

- If your primary focus is maximum durability and performance: PVD is an excellent and often necessary investment for tools, industrial components, and parts where failure from wear is not an option.

- If your primary focus is a premium, long-lasting aesthetic: PVD provides finishes for luxury goods like watches, jewelry, and high-end hardware that are far superior to traditional plating.

- If your primary focus is the lowest possible unit cost: Simpler methods like powder coating or painting will be significantly more economical for applications where extreme durability is not required.

Choosing the right surface finish means matching the process to the intended value and lifecycle of your product.

Summary Table:

| Factor | Impact on Cost & Value |

|---|---|

| Coating Material | Exotic materials (e.g., DLC) cost more than standard ones (e.g., TiN). |

| Part Complexity | Intricate shapes require custom setups, increasing the price. |

| Coating Thickness | Thicker, more precise coatings require longer machine cycle times. |

| Surface Preparation | Meticulous cleaning and polishing are essential for adhesion, adding to the cost. |

Ready to enhance your product's durability and performance with a premium PVD coating?

KINTEK specializes in advanced lab equipment and consumables for precise surface engineering. Our expertise ensures your materials gain superior hardness, corrosion resistance, and a lasting aesthetic finish. Let's discuss how PVD coating can add long-term value to your application—contact our experts today for a tailored solution!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition