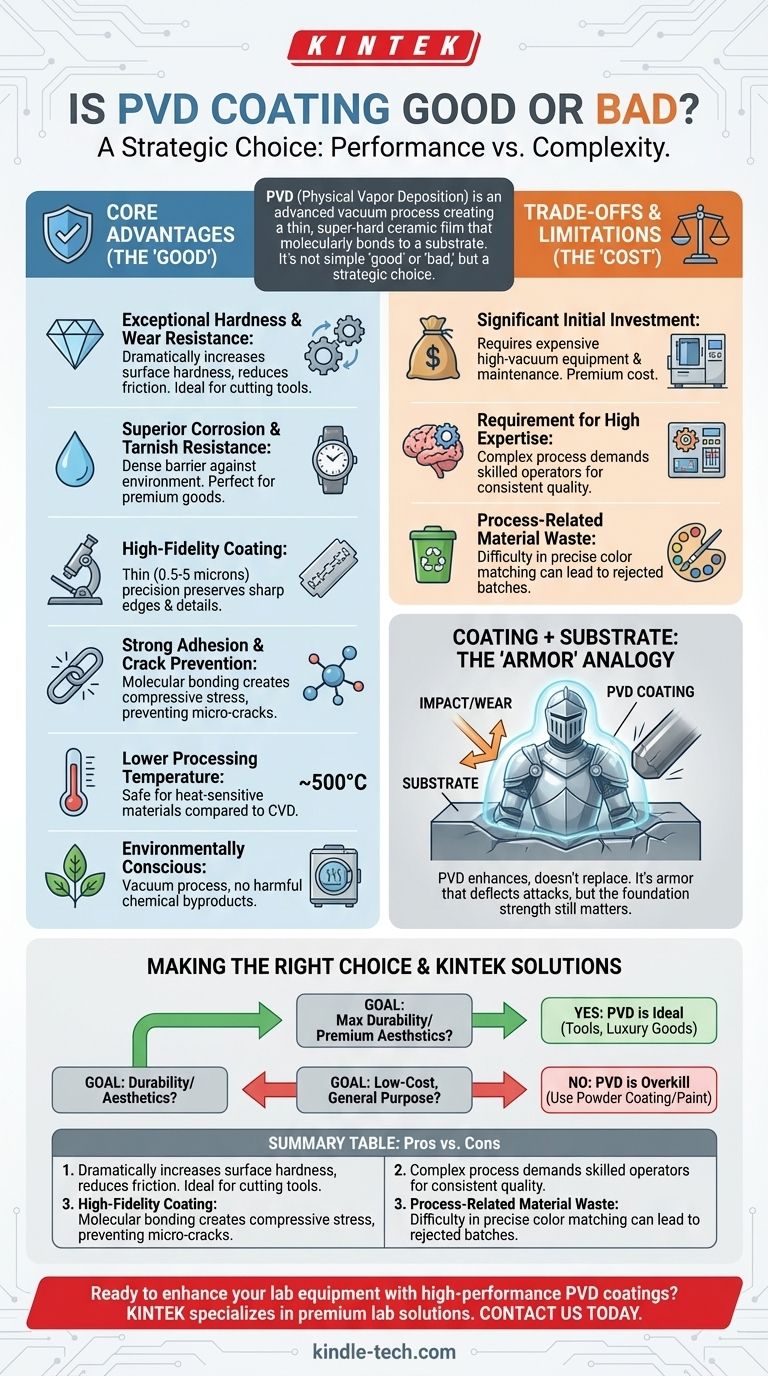

In almost every technical sense, PVD coating is an exceptionally effective and high-performance surface treatment. It is an advanced process that enhances a material's properties by depositing a thin, super-hard ceramic film in a vacuum. This film is not merely a layer of paint; it molecularly bonds to the substrate, creating a finish that is highly resistant to wear, corrosion, and tarnishing. Its value is determined by whether its specific strengths justify its complexity and cost for your application.

PVD coating is not a simple question of "good" or "bad," but a strategic choice of performance versus complexity. It delivers superior hardness and durability, but its high cost and technical requirements mean it is best reserved for applications where those specific benefits are critical.

The Core Advantages of PVD Technology

Physical Vapor Deposition (PVD) is favored in demanding industries for a clear set of reasons. The process fundamentally alters and improves the surface of a component.

Exceptional Hardness and Wear Resistance

PVD coatings add a layer of ceramic material, which dramatically increases the surface hardness of the substrate. This makes the component highly resistant to scratches and reduces friction.

This enhanced durability is why PVD is a standard in high-performance cutting tools, as it allows them to maintain a sharp edge for much longer.

Superior Corrosion and Tarnish Resistance

The deposited film is dense and non-porous, forming an excellent barrier against environmental factors.

This makes PVD-coated items highly resistant to corrosion, oxidation, and tarnishing, a key benefit for products like premium watches, jewelry, and architectural fixtures that must maintain their appearance over time.

High-Fidelity Coating

The PVD process deposits a very thin film, typically between 0.5 and 5 microns.

This precision ensures that sharp edges remain sharp and intricate surface details are preserved. It coats surfaces with excellent uniformity, which is critical for functional parts like cutting blades.

Strong Adhesion and Crack Prevention

Unlike plating, the PVD coating permeates and bonds with the surface on a molecular level, resulting in excellent adhesion.

Furthermore, the process typically creates compressive stress in the coating, which helps prevent the formation and spread of micro-cracks. This is particularly valuable in applications with intermittent force, like milling.

Lower Processing Temperature

PVD is conducted at relatively low temperatures (around 500°C), especially compared to alternative methods like Chemical Vapor Deposition (CVD).

This makes it a safe choice for many heat-sensitive materials that could be damaged or deformed by higher-temperature processes.

Environmentally Conscious

The PVD process takes place in a vacuum and does not produce harmful chemical byproducts, making it a more environmentally friendly coating method compared to traditional electroplating.

Understanding the Trade-offs and Limitations

While PVD offers significant benefits, it is not the right solution for every problem. Its primary drawbacks are related to cost and process complexity, not performance.

Significant Initial Investment

PVD coating requires specialized equipment, including a large, high-vacuum chamber. This machinery is expensive to purchase, operate, and maintain.

This cost is inevitably passed on to the final product, making PVD a premium finishing option.

Requirement for High Expertise

The PVD process is complex and requires a high level of technical skill to manage correctly.

Achieving consistent quality, color, and performance across batches demands significant operator expertise and process control.

Process-Related Material Waste

The reference to "aggressively destroying colors" likely points to the difficulty in achieving specific, consistent color targets.

If a batch does not meet a precise aesthetic specification, it may be rejected. This can lead to material wastage, increasing the overall cost and complexity of manufacturing.

How PVD Interacts with the Base Material

A critical concept to understand is that PVD is an enhancement, not a replacement for the underlying material's properties.

The Substrate is the Foundation

The final performance of a PVD-coated part is a combination of the coating and the substrate.

A hard PVD coating on a soft base material will protect against surface scratches, but it cannot prevent dents from a significant impact, as the soft material underneath will deform.

Enhancing, Not Replacing

Think of PVD coating as exceptionally strong armor. The armor can deflect attacks, but the strength of the soldier underneath still matters.

For example, a Titanium Nitride (TiN) PVD coating applied to a strong titanium alloy increases the alloy's fatigue limit and endurance. The coating and the substrate work together to create a superior result.

Making the Right Choice: Is PVD a Fit for Your Goal?

To decide if PVD is "good" for your project, you must weigh its premium performance against its cost and complexity.

- If your primary focus is maximum durability and performance: PVD is an ideal choice for components like cutting tools, molds, and high-wear industrial parts where longevity directly impacts operational efficiency.

- If your primary focus is premium aesthetics and longevity: PVD offers a superior, long-lasting finish for luxury goods, architectural hardware, and medical devices where resistance to tarnish and scratches is paramount.

- If your primary focus is low-cost, general-purpose coating: PVD is likely overkill. More traditional and cost-effective methods like powder coating or painting are better suited for non-critical applications.

Ultimately, viewing PVD coating as a specialized tool for specific, demanding jobs is the key to leveraging its power effectively.

Summary Table:

| Pros of PVD Coating | Cons of PVD Coating |

|---|---|

| Exceptional hardness & wear resistance | High initial investment & equipment cost |

| Superior corrosion & tarnish resistance | Requires significant technical expertise |

| High-fidelity coating preserves details | Potential for material wastage in color matching |

| Strong molecular adhesion to substrate | Premium cost compared to traditional methods |

| Low processing temperature (safe for heat-sensitive materials) | Complex process control needed for consistency |

| Environmentally friendly (no harmful byproducts) | Best suited for high-performance applications |

Ready to enhance your lab equipment with high-performance PVD coatings? KINTEK specializes in premium lab equipment and consumables, offering solutions that leverage advanced coatings like PVD to maximize durability, corrosion resistance, and longevity for your laboratory needs. Whether you're outfitting a research facility or upgrading tools for precision work, our expertise ensures you get the right surface treatment for optimal performance. Contact us today to discuss how PVD coating can benefit your specific application!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition