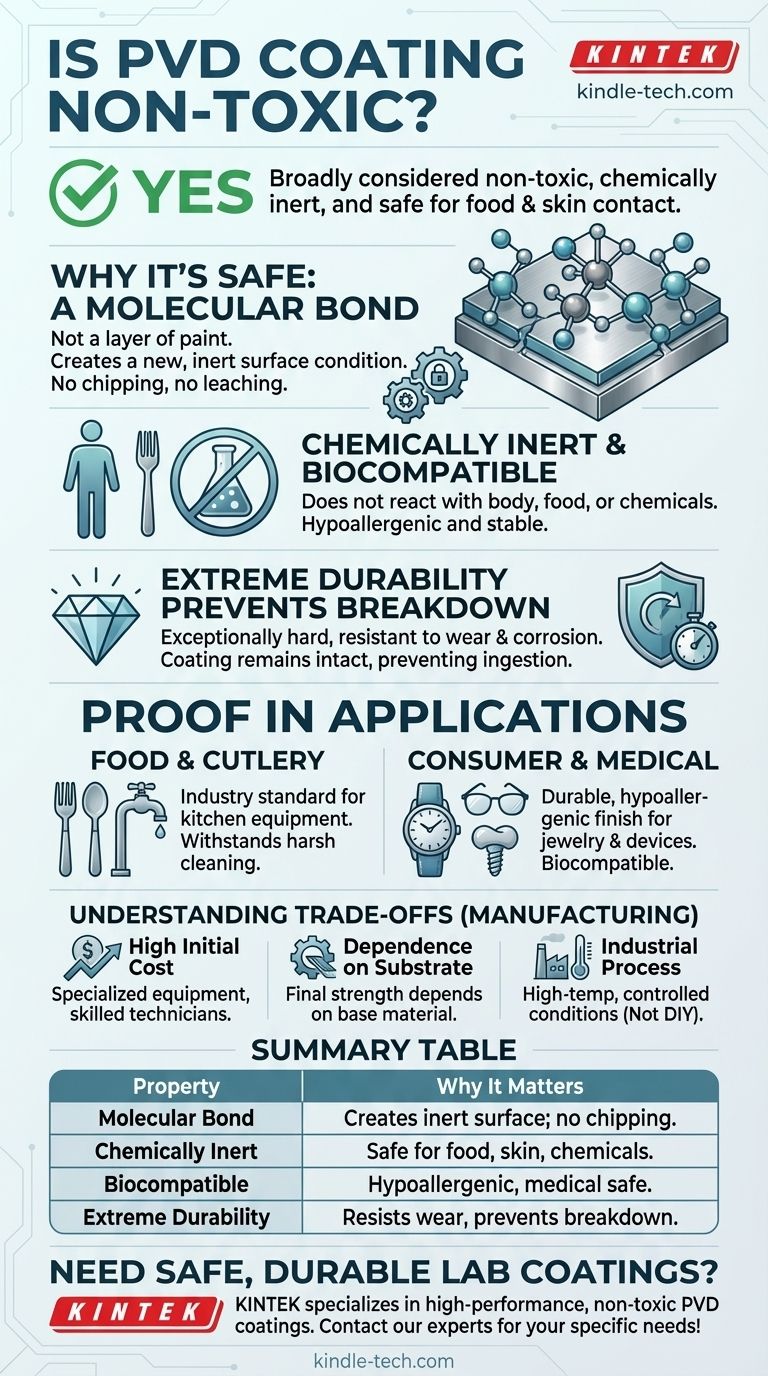

Yes, PVD coating is broadly considered non-toxic, chemically inert, and safe. This safety is a primary reason for its widespread adoption in industries with high standards, including food service, medical devices, and consumer goods. The process creates a highly durable, stable surface that does not react with its environment, making it safe for direct contact with both food and skin.

The core reason PVD coatings are non-toxic is that they form a molecular bond with the underlying material. This isn't a layer of paint that can chip or leach; it's a new, inert surface condition that is extremely stable, durable, and often biocompatible.

What Guarantees the Safety of PVD Coatings?

To understand why PVD is safe, you have to understand that it's fundamentally different from traditional coating methods like painting or electroplating.

A Molecular Bond, Not a Layer

PVD, or Physical Vapor Deposition, is a process performed in a high-vacuum chamber where a solid material is vaporized and then deposited onto a substrate, atom by atom.

This creates an incredibly thin film (0.5 to 5 microns) that is bonded at a molecular level. It's more accurate to think of it as creating a new surface condition on the metal rather than adding a separate layer on top.

Chemically Inert and Biocompatible

The materials used for PVD coatings are chosen for their specific properties, which often include being chemically and biologically inert.

This means they do not react with the human body, food, or most common chemicals. This stability is why PVD-coated items are frequently used in commercial kitchens and for medical applications.

Extreme Durability Prevents Breakdown

PVD coatings are exceptionally hard and highly resistant to corrosion, oxidation, and wear. This durability is a key component of their safety profile.

Because the surface doesn't easily scratch, chip, or corrode, there is no mechanism for the coating material to break away and be ingested or absorbed. The coating remains where it is supposed to be.

Common Applications as Proof of Safety

The industries that rely on PVD coatings serve as strong evidence of their non-toxic and stable nature.

Food and Cutlery Industry

PVD coatings are widely used on cutlery, faucets, and commercial kitchen equipment. Their ability to withstand constant use, harsh cleaning, and direct contact with food makes them an industry standard for both decorative and functional purposes.

Consumer Goods and Jewelry

From watches to eyeglass frames, PVD provides a durable and hypoallergenic finish. Its biocompatibility ensures that the coating itself won't cause skin irritation, a common concern with plated or coated jewelry.

Understanding the Trade-offs

While the final product is exceptionally safe, the PVD process itself has specific characteristics and limitations. The trade-offs are related to manufacturing, not toxicity.

High Initial Cost and Complexity

The PVD process requires specialized, expensive equipment, including a large vacuum chamber, and must be performed by highly skilled technicians. This makes the initial cost higher than for traditional finishes.

Dependence on the Substrate

The final properties of a PVD-coated object are a combination of the coating and the underlying base material. The coating adds hardness and corrosion resistance, but the object's overall strength is still determined by the metal it is applied to, such as stainless steel or titanium.

An Industrial Process

PVD is not a DIY application. It is a high-temperature (250°C to 750°C) industrial process that must be performed under tightly controlled conditions to ensure a proper molecular bond and consistent finish.

Making the Right Choice for Your Goal

The non-toxic nature of PVD coating makes it a superior choice for many applications, but your specific goal will determine its value.

- If your primary focus is food safety: PVD-coated cutlery and kitchenware are an excellent choice due to their inertness and durability, ensuring no material leaches into your food.

- If your primary focus is skin contact: Look for products advertising biocompatible PVD coatings, especially for watches or jewelry, to get a durable, hypoallergenic finish.

- If your primary focus is environmental impact: PVD is considered a more environmentally friendly process than many traditional coating methods like electroplating, producing less harmful waste.

Ultimately, choosing a PVD-coated product means selecting a finish engineered for superior safety and longevity.

Summary Table:

| Property | Why It Matters |

|---|---|

| Molecular Bond | Creates a new, inert surface; doesn't chip or leach like paint. |

| Chemically Inert | Does not react with food, skin, or chemicals, ensuring safety. |

| Biocompatible | Hypoallergenic and safe for prolonged skin contact and medical use. |

| Extreme Durability | Resists wear and corrosion, preventing material breakdown. |

Need a safe, durable coating for your laboratory equipment or consumables? KINTEK specializes in high-performance PVD coatings that are non-toxic, chemically inert, and perfect for demanding lab environments. Ensure the safety and longevity of your equipment—contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose