Yes, by definition, pyrolysis is a destructive process. It uses high temperatures in an oxygen-free environment to cause the thermal decomposition of materials, breaking down complex organic matter into simpler, smaller molecules. However, this destruction is not an end in itself; it is a highly controlled method of transformation. The goal is not to eliminate waste but to deconstruct it into valuable new resources.

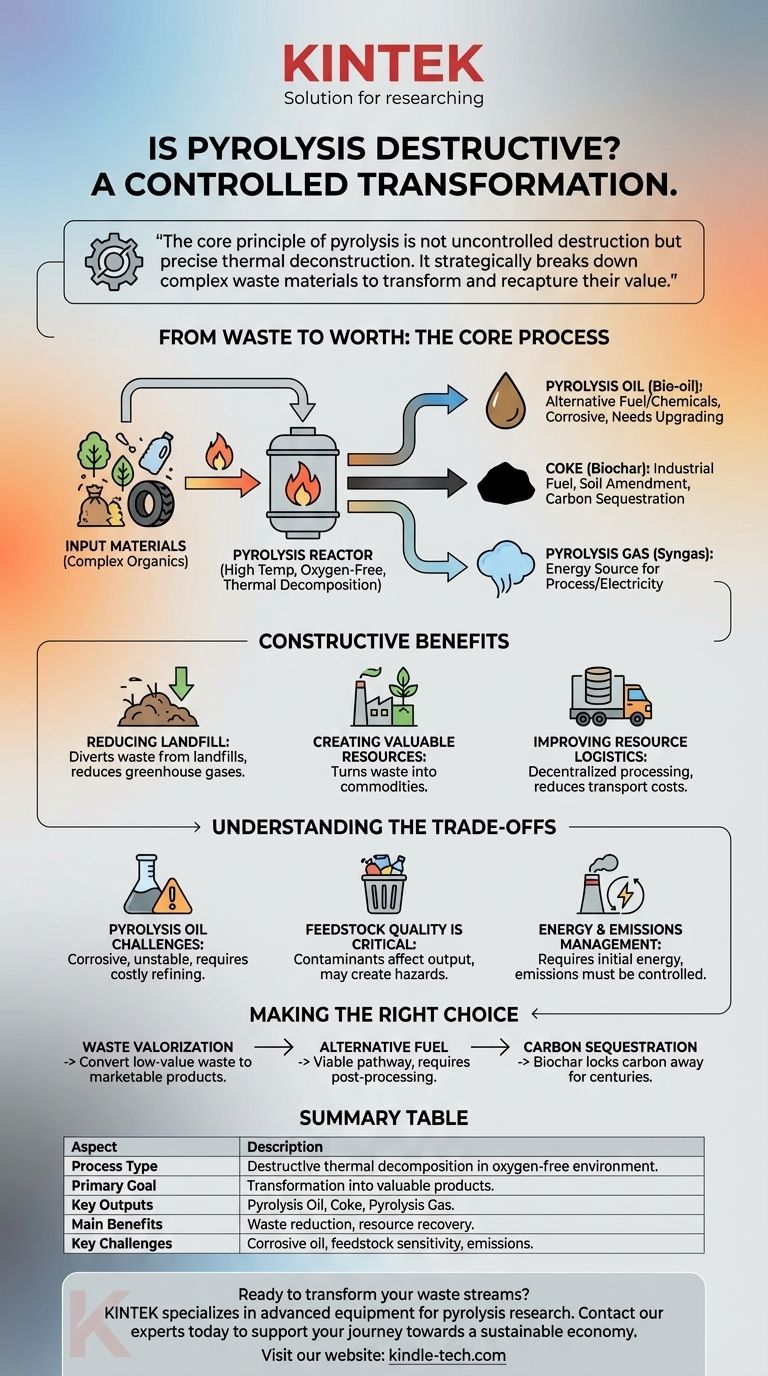

The core principle of pyrolysis is not uncontrolled destruction but precise thermal deconstruction. It strategically breaks down complex waste materials not to destroy their value, but to transform and recapture it in the form of useful fuels, gases, and solid carbon.

From Waste to Worth: The Core Process

Pyrolysis should be understood as a form of advanced recycling or resource recovery. It fundamentally alters the chemical structure of feedstock material to create products with entirely new applications, preventing the material from ending up in a landfill.

What "Destruction" Really Means

The term "destructive" in this context refers to thermal decomposition. Unlike combustion (burning), which requires oxygen and releases energy rapidly as heat and light, pyrolysis uses heat without oxygen. This prevents the material from burning and instead causes its chemical bonds to break apart.

The Goal is Transformation, Not Elimination

The process is designed to convert low-value or waste materials, such as biomass, plastics, or used tires, into a portfolio of valuable outputs. This is a constructive outcome born from a destructive method.

A Self-Sustaining Cycle

In many pyrolysis systems, the process is engineered for maximum efficiency. The pyrolysis gas produced is often captured and used to generate the heat needed to sustain the reaction, significantly reducing the need for external energy inputs.

The Constructive Benefits of Pyrolysis

While the process is destructive to the input material, its overall impact is constructive, addressing significant environmental and logistical challenges.

Reducing Landfill and Waste

Pyrolysis offers a powerful alternative to landfills for organic and polymer-based waste. It allows for the recovery of value from materials that might otherwise take centuries to degrade, releasing harmful greenhouse gases in the process.

Creating Valuable Resources

The outputs of pyrolysis are not waste products but commodities.

- Pyrolysis Oil (Bio-oil): A liquid that can be used as an alternative fuel or further refined into advanced biofuels and chemicals.

- Coke (Biochar): A stable, carbon-rich solid that can be used as an industrial fuel, a soil amendment in agriculture, or for producing activated carbon.

- Pyrolysis Gas (Syngas): A mixture of combustible gases that, as noted, can power the pyrolysis plant itself or be used to generate electricity.

Improving Resource Logistics

For materials like biomass, pyrolysis offers a significant advantage. It can be performed at smaller, decentralized scales, converting bulky, low-density solids into easily stored and transported energy-dense liquids. This dramatically reduces transportation costs and logistical complexity.

Understanding the Trade-offs and Challenges

To maintain an objective view, it's critical to acknowledge that the process and its products are not without complexities. The "destructive" nature of the process can create outputs with challenging properties.

The Nature of Pyrolysis Oil

Pyrolysis oil is not a direct substitute for crude oil. It has a high oxygen content, which makes it corrosive, thermally unstable, and immiscible with conventional fossil fuels. It often requires significant upgrading and refinement before it can be used in standard engines or refineries, adding cost and complexity.

Feedstock Quality is Critical

The quality and consistency of the outputs are directly dependent on the input material. Contaminated or mixed waste streams can produce lower-quality oils and chars, requiring more intensive purification and potentially creating hazardous byproducts that must be managed.

Energy and Emissions Management

While the process can be largely self-powering, it requires an initial energy input to start. Furthermore, the entire system must be carefully engineered to manage emissions and ensure that harmful compounds are not released into the atmosphere, which is essential for it to be a net positive for the environment.

Making the Right Choice for Your Goal

Viewing pyrolysis as simply "destructive" is inaccurate. It is a sophisticated engineering tool for chemical transformation.

- If your primary focus is waste valorization: Pyrolysis is an extremely effective technology for converting low-value organic and plastic waste streams into higher-value marketable products.

- If your primary focus is alternative fuel production: It is a viable pathway, but you must account for the necessary post-processing and upgrading required to turn the raw pyrolysis oil into a stable, usable fuel.

- If your primary focus is carbon sequestration: The solid biochar (coke) produced from biomass is a highly stable form of carbon that can lock carbon away for centuries when used as a soil amendment.

Ultimately, pyrolysis redefines destruction as a precise and valuable first step toward creating a more circular and sustainable economy.

Summary Table:

| Pyrolysis Aspect | Description |

|---|---|

| Process Type | Destructive thermal decomposition in an oxygen-free environment. |

| Primary Goal | Transformation of waste into valuable products, not elimination. |

| Key Outputs | Pyrolysis Oil (Bio-oil), Coke (Biochar), Pyrolysis Gas (Syngas). |

| Main Benefits | Waste reduction, resource recovery, creation of alternative fuels and soil amendments. |

| Key Challenges | Corrosive oil requiring upgrading, feedstock sensitivity, emissions management. |

Ready to transform your waste streams into valuable resources? KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and process optimization. Whether you are developing new biofuels, characterizing biochar, or optimizing your pyrolysis process, our precise and reliable tools are designed to meet the demanding needs of your laboratory. Contact our experts today to discuss how we can support your journey towards a more sustainable and circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- Is pyrolysis pollution free? A Balanced Look at Its Environmental Impact

- What happens in a calciner? A Deep Dive into Industrial Thermal Transformation

- How does pyrolysis machine work? Turn Waste into Valuable Resources with Thermal Decomposition

- What are the advantages of spray pyrolysis? Achieve Cost-Effective, Scalable Thin Film Production

- What is a pyrolysis reactor? A Guide to Converting Waste into Valuable Resources

- What is the best catalyst for plastic pyrolysis? Match Your Catalyst to Your Plastic Waste Goals

- What type of plastic is best for pyrolysis? Maximize Oil Yield and Quality with Polyolefins

- What are the factors affecting pyrolysis yield? Mastering the Control of Char, Oil, and Gas Production