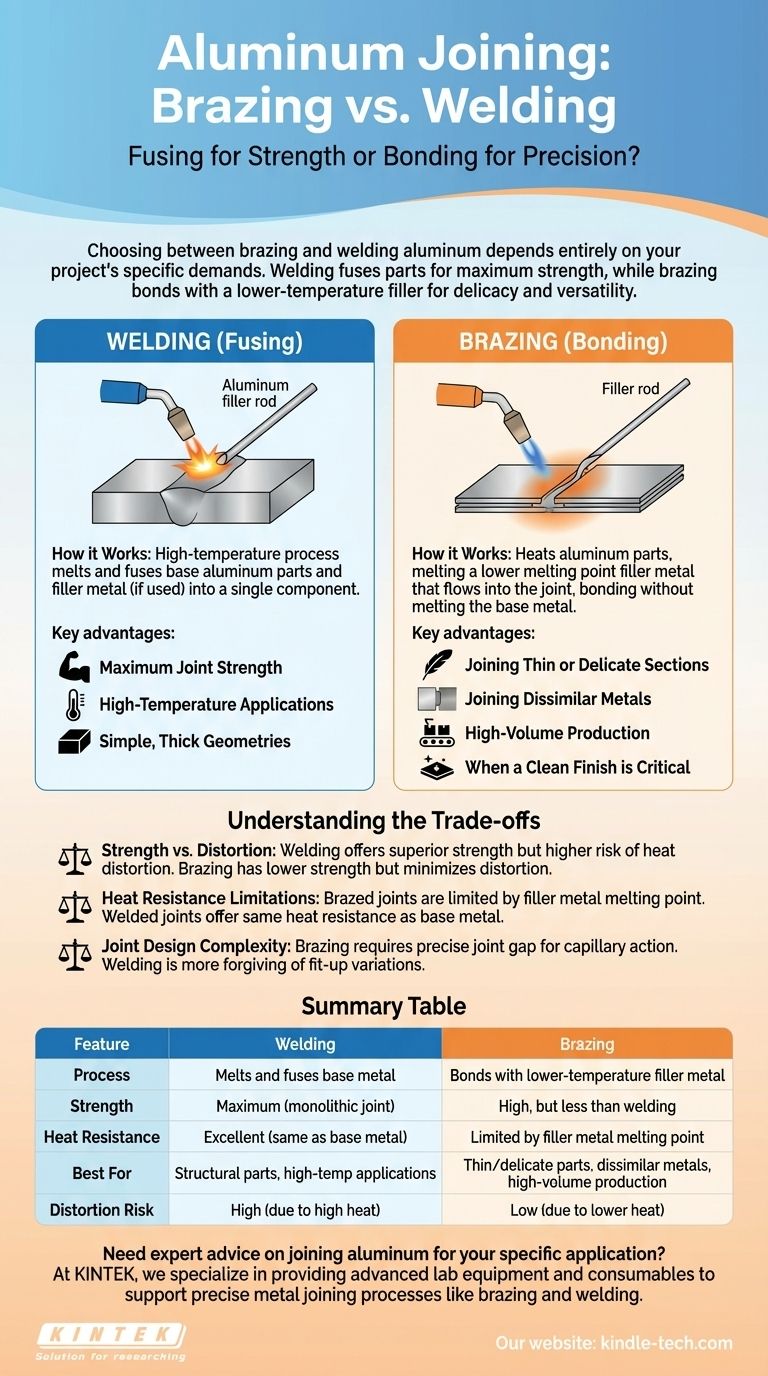

Choosing between brazing and welding aluminum depends entirely on your project's specific demands. Welding fuses the aluminum parts together, creating a single, continuous piece that offers maximum strength and heat resistance. Brazing, conversely, uses a lower temperature to bond the aluminum with a separate filler metal, providing advantages for delicate components, joining different types of metals, and high-volume production.

The fundamental choice is not about which process is "better" overall, but which one aligns with your specific priorities. Welding prioritizes ultimate strength by melting the base metal, whereas brazing prioritizes precision and versatility by using a lower-temperature bonding process.

The Fundamental Difference: Fusing vs. Bonding

How Welding Works

Welding is a high-temperature process that melts the base aluminum parts at the join. A filler metal, also aluminum, is typically added, and all materials melt, mix, and solidify together. This creates a single, monolithic component.

The result is a joint that is metallurgically part of the original pieces, offering exceptional strength.

How Brazing Works

Brazing heats the aluminum parts to a temperature hot enough to melt a filler metal, but not hot enough to melt the aluminum itself. This filler metal, which has a lower melting point, is drawn into the tight-fitting joint by capillary action.

Upon cooling, the filler metal solidifies and forms a strong metallurgical bond between the aluminum pieces without ever melting them.

When to Choose Welding for Aluminum

For Maximum Joint Strength

Because welding melts and fuses the parent metal, the resulting joint is exceptionally strong. For structural components or parts under high stress, welding is almost always the superior method.

For High-Temperature Applications

A welded joint is essentially a continuous piece of aluminum. This gives it significant heat resistance, making it the only suitable choice for parts that will operate in high-temperature environments.

For Simple, Thick Geometries

Welding is highly effective for joining thick sections of aluminum where the high heat input is less likely to cause warping or burn-through compared to thinner materials.

When to Choose Brazing for Aluminum

Joining Thin or Delicate Sections

Aluminum is an excellent thermal conductor, meaning heat from welding spreads rapidly, often leading to warping or melting through on thin materials. Brazing's lower temperature significantly reduces the risk of this distortion, making it ideal for delicate parts.

Joining Dissimilar Metals

Brazing is superior for joining aluminum to other metals like copper or steel. This is extremely difficult or impossible to achieve with conventional welding, but brazing's bonding process makes it a reliable solution.

For High-Volume Production

Brazing lends itself well to automation and high-volume projects. Processes like vacuum brazing create extremely clean, consistent joints with excellent part-to-part repeatability and minimal need for post-process finishing.

When a Clean Finish is Critical

Brazing, especially when done in a controlled atmosphere like a vacuum, produces parts free from oxidation with a very clean appearance. This can reduce or eliminate the need for secondary cleaning operations.

Understanding the Trade-offs

Strength vs. Distortion

This is the central trade-off. Welding delivers superior strength but carries a high risk of heat-induced distortion (warping), especially in aluminum. Brazing sacrifices some ultimate strength and heat resistance in exchange for a lower-risk process that protects the dimensional integrity of the parts.

Heat Resistance Limitations

A brazed joint's service temperature is limited by the melting point of the filler metal used. If the part is exposed to temperatures that approach this melting point, the joint will fail. A welded joint does not have this limitation.

Joint Design Complexity

Brazing relies on capillary action, which requires a very specific and consistent gap between the parts being joined. Welding is generally more forgiving of variations in fit-up and joint preparation.

Making the Right Choice for Your Goal

By understanding the core purpose of your project, you can select the right process with confidence.

- If your primary focus is structural integrity, load-bearing capacity, or high-temperature performance: Welding is the superior choice as it creates a monolithic joint with strength comparable to the base aluminum.

- If your primary focus is joining thin materials, connecting aluminum to a different metal, or minimizing part distortion: Brazing is the better option due to its lower heat input and unique bonding capabilities.

- If your primary focus is high-volume manufacturing requiring clean, consistent joints: Brazing, particularly automated or vacuum brazing, offers significant advantages in efficiency and final appearance.

By aligning the process capabilities with your project's demands, you can confidently select the joining method that ensures its integrity and success.

Summary Table:

| Feature | Welding | Brazing |

|---|---|---|

| Process | Melts and fuses base metal | Bonds with lower-temperature filler metal |

| Strength | Maximum (monolithic joint) | High, but less than welding |

| Heat Resistance | Excellent (same as base metal) | Limited by filler metal melting point |

| Best For | Structural parts, high-temp applications | Thin/delicate parts, dissimilar metals, high-volume production |

| Distortion Risk | High (due to high heat) | Low (due to lower heat) |

Need expert advice on joining aluminum for your specific application?

At KINTEK, we specialize in providing advanced lab equipment and consumables to support precise metal joining processes like brazing and welding. Whether you're working with delicate components or high-volume production, our solutions help ensure integrity and success.

Contact us today to discuss how we can meet your laboratory's equipment needs!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the defects in sintered parts? Avoid Warping, Cracking, and Porosity Issues

- Why is high-temperature vacuum heat treatment critical for Cr-Ni steel? Optimize Strength & Surface Integrity

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance