In short, annealing is required whenever a fabrication process has made a material too hard, brittle, or internally stressed to be useful or to undergo further work. Processes like casting, cold rolling, or welding create these undesirable conditions, and annealing acts as a controlled "reset," restoring the material's ductility and relieving internal stress at a microscopic level.

The core purpose of manufacturing is to shape materials, but these processes often leave behind a hidden legacy of internal stress and brittleness. Annealing is the essential corrective procedure used to reverse this damage, trading some hardness for crucial ductility and structural stability.

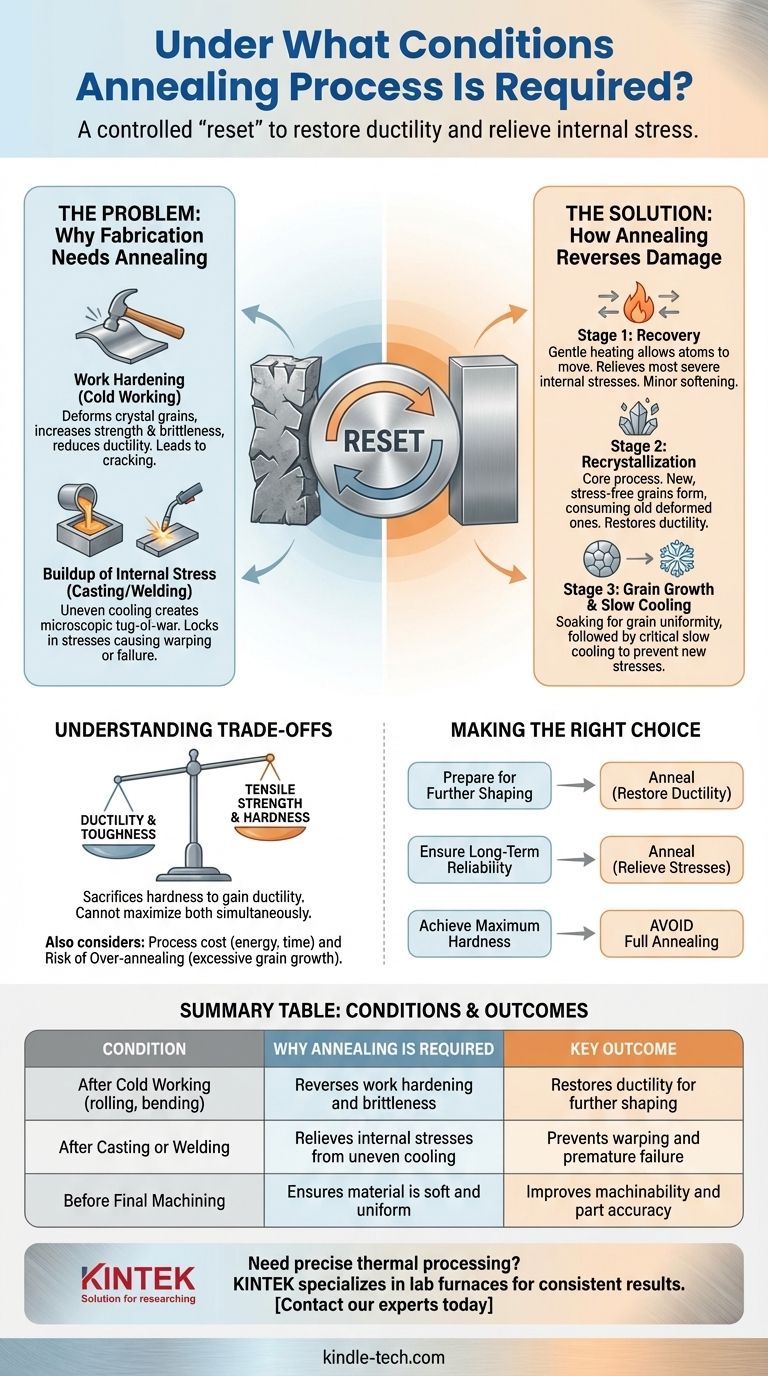

Why Manufacturing Processes Create the Need for Annealing

Manufacturing is, by nature, a forceful process. Whether casting molten metal or bending it cold, these actions fundamentally alter the material's internal crystal structure, often for the worse.

The Problem of Work Hardening

When you bend, roll, or draw a metal at room temperature (a process called cold working), you are deforming its internal crystal grains. This deformation makes the material significantly stronger and harder, but it also drastically reduces its ductility, making it brittle.

After a certain amount of cold work, the material becomes so brittle that any further attempt to shape it will cause it to crack and fail. Annealing is required to soften the material and restore its ductility so that work can continue.

The Buildup of Internal Stress

Processes that involve heat, such as casting or welding, are also prime candidates for creating stress. As the material cools, different sections cool at different rates.

This uneven cooling creates a microscopic tug-of-war inside the material, locking in internal stresses. These hidden stresses act as weak points, which can lead to unexpected warping or catastrophic failure later on, even under normal operating loads. Annealing relieves these stresses, creating a more stable and reliable final part.

How Annealing Reverses the Damage

Annealing isn't a single event but a three-stage process of controlled heating and cooling. Each stage plays a specific role in repairing the internal structure of the material.

Stage 1: Recovery

As the material is gently heated, the atoms gain just enough energy to move slightly. This initial phase, known as recovery, allows the most severe internal stresses to relax.

While it provides some softening, the material's core mechanical properties are not significantly changed, as the deformed crystal grains remain in place.

Stage 2: Recrystallization

This is the heart of the annealing process. As the temperature rises to a specific point (the recrystallization temperature), something remarkable happens. New, perfectly formed, stress-free crystals (grains) begin to form within the old, deformed structure.

These new grains grow and eventually consume the old, damaged ones entirely. This process effectively erases the negative effects of cold working, restoring the material's ductility and toughness.

Stage 3: Grain Growth and Slow Cooling

After recrystallization is complete, the material is "soaked" at that temperature. If held too long, the new grains can merge and become too large, which can sometimes reduce strength. Precise control is key.

Finally, the material is cooled very slowly. This slow cooling is critical to prevent new internal stresses from forming as the material contracts, ensuring a uniform, stress-free final state.

Understanding the Trade-offs

Annealing is a powerful tool, not a magic solution. Its benefits come with important trade-offs that must be considered.

The Primary Trade-off: Ductility vs. Hardness

Annealing makes a material more ductile, tougher, and easier to shape. However, this always comes at the expense of tensile strength and hardness. You cannot use annealing to create a material that is simultaneously max-strength and max-ductility. The process deliberately sacrifices hardness to gain ductility.

The Cost of Processing

Annealing is an energy-intensive process that requires large, specialized furnaces, precise temperature monitoring, and significant time. The heating, soaking, and especially the slow cooling cycles can take many hours, adding tangible cost and time to a production workflow.

The Risk of Improper Control

The process must be executed with precision. Heating the material too high or holding it for too long can cause excessive grain growth. These overly large grains can make the material weaker than desired, a condition known as over-annealing.

Making the Right Choice for Your Goal

Whether to anneal depends entirely on the material's history and its intended future use.

- If your primary focus is to prepare a material for further shaping: Annealing is essential after significant cold working to restore ductility and prevent cracking during subsequent forming operations.

- If your primary focus is to ensure long-term structural reliability: Annealing is required after casting or welding to relieve locked-in internal stresses that could cause premature failure.

- If your primary focus is to achieve maximum hardness: You should avoid a full annealing process, as it is designed specifically to soften materials and reduce hardness.

Ultimately, applying the annealing process is about making a deliberate choice to control your material's properties for a specific outcome.

Summary Table:

| Condition | Why Annealing is Required | Key Outcome |

|---|---|---|

| After Cold Working (e.g., rolling, bending) | Reverses work hardening and brittleness | Restores ductility for further shaping |

| After Casting or Welding | Relieves internal stresses from uneven cooling | Prevents warping and premature failure |

| Before Final Machining | Ensures material is soft and uniform | Improves machinability and part accuracy |

Need precise thermal processing for your materials? The annealing process is critical for achieving the right balance of material properties, but it requires expert control and reliable equipment. KINTEK specializes in lab furnaces and thermal processing solutions that deliver accurate temperature profiles and consistent results for your R&D or production needs.

Contact our experts today to discuss how our equipment can help you optimize your annealing cycles and improve your material performance.

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

People Also Ask

- What is the importance of precise programmed temperature control in a high-temperature furnace? Master Co-Sintering

- How do you sterilize glassware without an autoclave? A Step-by-Step Guide to Dry Heat Sterilization

- What are the primary functions of a laboratory oven in MnO2-GAC synthesis? Optimize Your Catalyst Preparation

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do high-temperature furnaces and ceramic crucibles impact Li-ion battery stability? Master Precision Synthesis