Ultimately, pellet quality is a direct result of meticulous process control. While many variables are at play, the quality of the final product is most directly influenced by the characteristics of your raw material—specifically its moisture content, particle size, and composition. These factors dictate not only the final pellet's integrity but also the efficiency and stability of the entire pelletizing operation.

While raw materials are the foundation, achieving consistent high-quality pellets requires a holistic systems approach. You must actively manage the interplay between feedstock preparation, pellet mill settings, and post-production handling to create a durable, energy-dense, and uniform product.

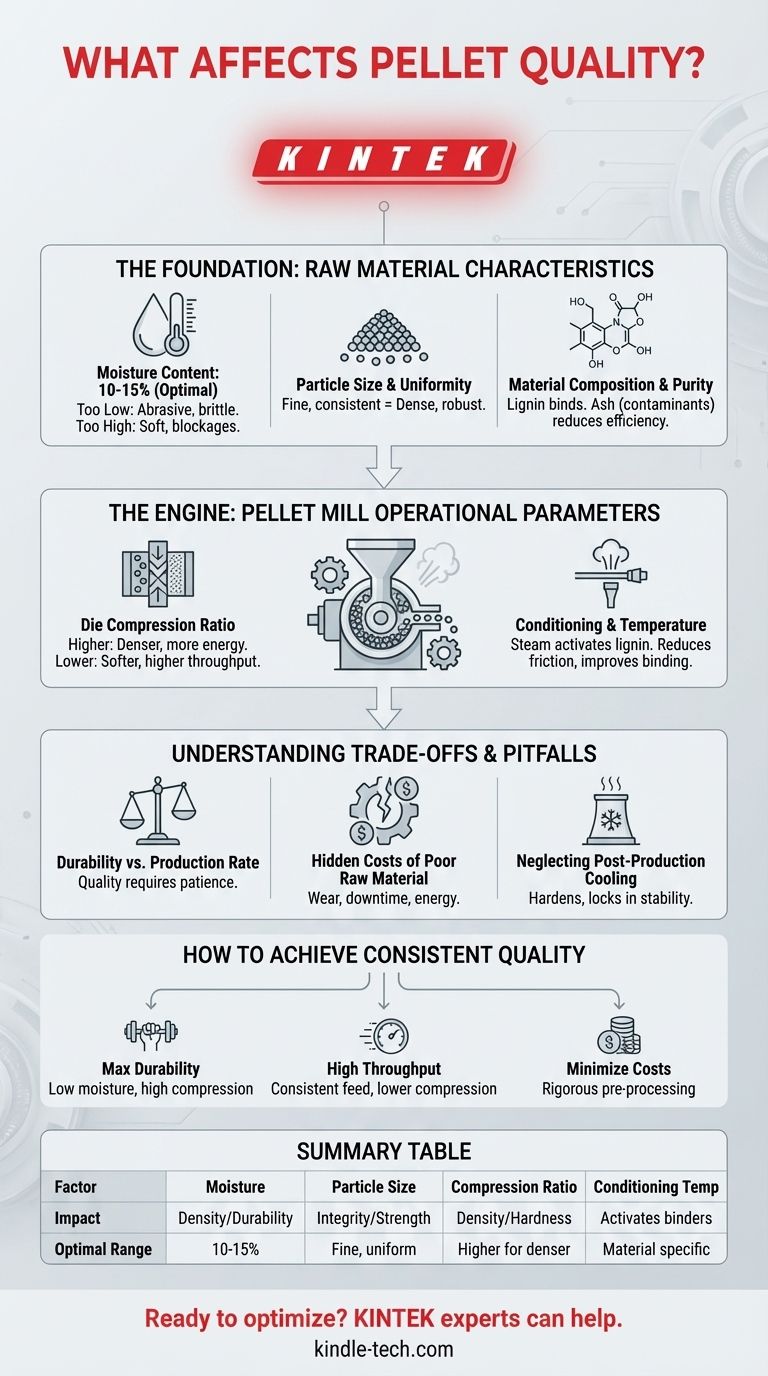

The Foundation: Raw Material Characteristics

The phrase "garbage in, garbage out" is profoundly true in pellet production. The state of your raw material before it ever enters the mill is the single greatest predictor of your success.

The Critical Role of Moisture Content

Moisture acts as both a lubricant and a binding agent during pelletization. However, there is a narrow optimal range, typically between 10-15%.

If moisture is too low, the material becomes excessively abrasive. This increases friction in the die, leading to higher energy consumption, accelerated equipment wear, and poorly formed, brittle pellets that crumble easily.

If moisture is too high, the excess water turns to steam inside the die channel. This steam pressure works against the compaction process, resulting in low-density, soft pellets. It can also cause the material to choke the die, leading to blockages and costly downtime.

Particle Size and Uniformity

The goal of pelletizing is to compact loose material into a dense, uniform shape. This is only possible if the initial particles are small and consistent in size.

Large or irregular particles create voids and fracture points within the pellet, severely compromising its mechanical durability. A properly prepared feedstock, ground to a consistent, fine texture, flows smoothly through the die and compacts evenly, producing a dense and robust final product.

Material Composition and Purity

The type of biomass used (e.g., hardwood, softwood, agricultural residue) directly impacts the pellet's properties. Factors like lignin content—a natural polymer in wood that acts as a binder when heated—affect how well the pellet holds together.

Furthermore, contaminants like dirt, sand, or bark increase the final ash content of the pellets. High-ash pellets are undesirable as they burn less efficiently and can lead to slagging and fouling in combustion systems.

The Engine: Pellet Mill Operational Parameters

Even with perfect raw material, incorrect mill settings will produce a substandard product. The pellet mill is where pressure and heat transform the feedstock into its final state.

Die Compression Ratio

The compression ratio—the length of the die channel relative to its diameter—is a critical setting. A higher compression ratio forces more compaction, producing denser, more durable pellets. However, it also requires more energy and increases the risk of blockages if the feedstock isn't perfect.

Conversely, a lower compression ratio allows for higher throughput with less energy but typically yields a softer, less durable pellet.

Conditioning and Temperature

Many systems pre-condition the feedstock with steam before it enters the pellet die. This process adds heat and moisture, which softens the material and activates the natural lignin.

Proper conditioning reduces friction, lowers energy consumption, and significantly improves the binding process, leading to a stronger, glossier pellet. Achieving the correct temperature is essential for activating these binding properties without overheating the material.

Understanding the Trade-offs and Pitfalls

Achieving elite pellet quality is an exercise in balancing competing priorities. Understanding these trade-offs is key to avoiding common operational failures.

Durability vs. Production Rate

There is a fundamental trade-off between the speed of production and the quality of the output. Pushing for maximum tons per hour by increasing feed rates or using a lower compression die will almost always result in a pellet with lower durability and density. True quality requires a patient, controlled process.

The Hidden Costs of Poor Raw Material

Using inconsistent or improperly prepared feedstock does more than just produce bad pellets. It dramatically increases operational costs through accelerated wear on expensive dies and rollers, frequent downtime for cleaning clogged equipment, and higher energy consumption per ton produced.

Neglecting Post-Production Cooling

Pellets exit the die at high temperatures and are relatively soft and fragile. They must be cooled correctly in a controlled manner. This cooling process hardens the pellet and removes the final bit of excess moisture, locking in its durability and ensuring its stability for storage and transport. Skipping or rushing this step will undo much of the hard work done in the mill.

How to Achieve Consistent Pellet Quality

Your operational strategy should be dictated by your primary goal. By focusing your efforts on the most relevant variables, you can optimize for a specific outcome.

- If your primary focus is maximizing durability and energy density: Prioritize a low-moisture, uniform feedstock and use a higher die compression ratio, accepting that this may slightly lower your hourly output.

- If your primary focus is achieving high production throughput: Concentrate on maintaining a perfectly consistent feed rate and moisture level to prevent clogs, and consider using a lower compression die while accepting the trade-off in pellet hardness.

- If your primary focus is minimizing operational costs: Invest heavily in rigorous raw material pre-processing (drying, grinding, and cleaning) to reduce wear on your pellet mill components and lower overall energy consumption.

By viewing pellet production as an integrated system from raw material intake to final cooling, you can shift from reactive problem-solving to proactive quality control.

Summary Table:

| Key Factor | Impact on Pellet Quality | Optimal Range / Goal |

|---|---|---|

| Moisture Content | Binds particles; affects density & durability | 10-15% (typical) |

| Particle Size | Determines pellet integrity & mechanical strength | Fine, uniform particles |

| Die Compression Ratio | Controls pellet density and hardness | Higher ratio for denser pellets |

| Conditioning Temperature | Activates natural binders (e.g., lignin) | Specific to material composition |

Ready to optimize your pellet production for maximum durability and efficiency? The experts at KINTEK are here to help. We specialize in lab equipment and consumables for analyzing and preparing biomass feedstocks, ensuring your process is built on a foundation of quality control.

Contact us today to discuss how our solutions can help you achieve consistent, high-quality pellets and reduce operational costs.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation

- What is the function of a planetary ball mill for c-LLZO precursors? Master Solid Electrolyte Prep

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What is the difference between a ball mill and a planetary mill? Choose the Right Grinding Tool for Your Lab

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results