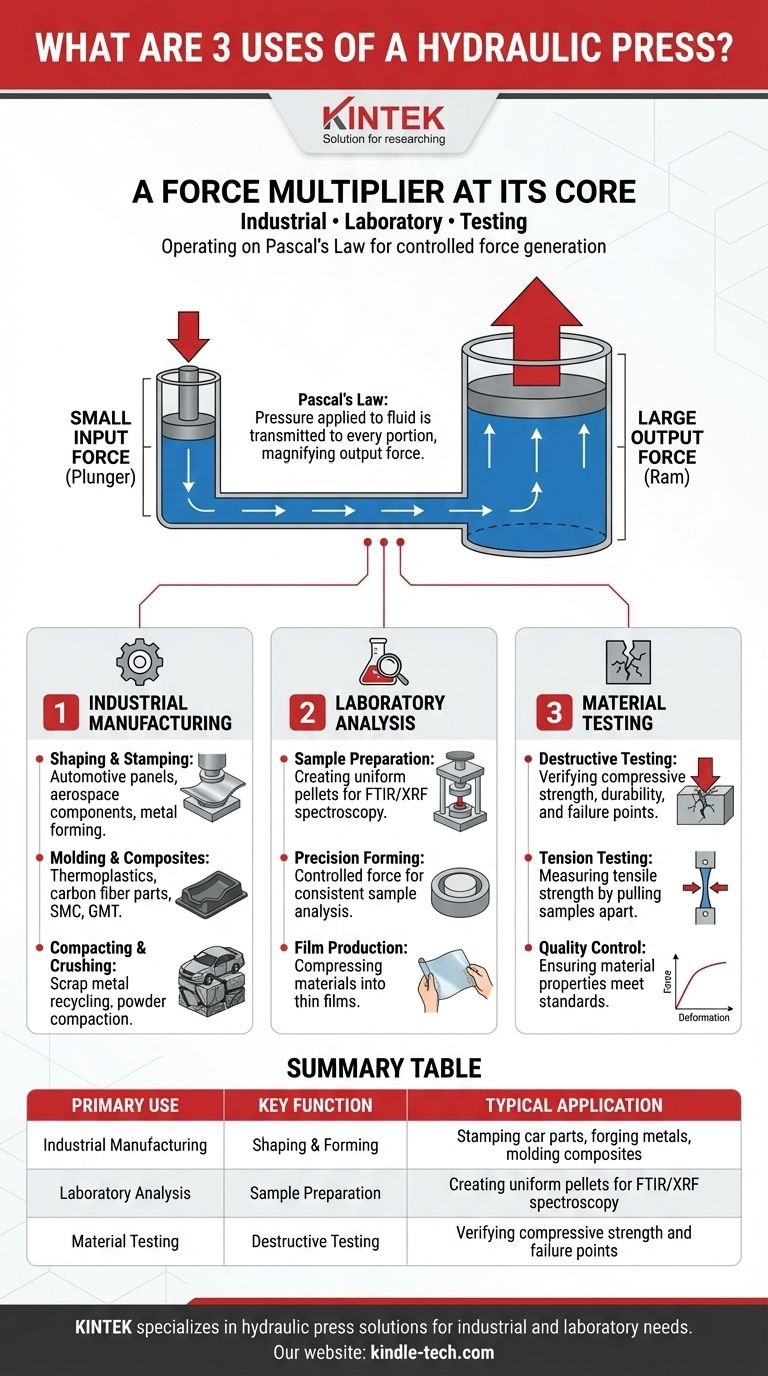

At its core, a hydraulic press is a force multiplier. While it has countless applications, three primary uses stand out: industrial manufacturing for shaping and stamping metal parts, laboratory sample preparation for scientific analysis, and destructive testing to verify material strength. These functions leverage the machine's ability to generate immense, controlled force from a simple physical principle.

A hydraulic press is remarkably versatile because it operates on Pascal's Law, allowing a small initial force to be converted into a massive output force. This principle makes it equally effective at crushing a car for recycling and delicately preparing a sample for microscopic analysis.

The Principle of Force Multiplication

The power of a hydraulic press doesn't come from magic, but from a fundamental principle of fluid mechanics discovered in the 17th century.

How a Hydraulic Press Works

A hydraulic press uses two connected cylinders of different sizes, both filled with an incompressible fluid like oil. A small force is applied to the smaller cylinder (the plunger).

According to Pascal's Law, pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

This means the pressure in the small cylinder is equal to the pressure in the large cylinder. Because the large cylinder has a much greater surface area, the resulting force it exerts is proportionally magnified. This is how a small effort can generate enough force to bend steel.

Why This Principle Matters

This ability to multiply force is what makes the press so adaptable. The force is not only powerful but also highly controllable.

By adjusting the fluid pressure, operators can apply precise amounts of force required for a specific task, whether it's gently forming a composite material or stamping a car door.

Core Application 1: Industrial Manufacturing & Metalworking

In industrial settings, the hydraulic press is a workhorse, valued for its raw power and reliability in shaping difficult materials.

Forging, Stamping, and Forming

This is the most common use. Presses are used to stamp sheets of metal into automotive body panels, forge solid blocks of steel into engine components, and bend thick plates for aerospace and construction industries.

Molding and Composites

Beyond metal, hydraulic presses are used to mold various materials. This includes forming thermoplastics, carbon fiber composites for high-performance applications, and other materials like sheet molded composites (SMC) and glass mat transfer (GMT).

Compacting and Crushing

The immense force generated is perfect for high-pressure compaction. This can range from crushing junked cars into dense, recyclable blocks to compressing powders into solid forms.

Core Application 2: Scientific and Laboratory Analysis

In a laboratory, the hydraulic press is a tool of precision. Its purpose is not mass production but creating perfect conditions for analysis and testing.

Sample Preparation for Spectroscopy

For techniques like FTIR (Fourier-transform infrared) or XRF (X-ray fluorescence) spectroscopy, the sample must be uniform. A lab press compresses powdered material, often mixed with a salt like KBr, into a thin, homogenous pellet or film.

This preparation ensures the analytical instrument gets a clear, consistent, and representative reading from the sample, free from interference caused by an uneven surface or density.

Material Strength Testing

Engineers and material scientists use hydraulic presses to test the limits of materials. By applying a measured and increasing force, they can determine a material's compressive strength, durability, and failure point.

Some presses are even adapted for tension testing, where they pull a sample apart to measure its tensile strength.

Understanding the Trade-offs

While incredibly useful, the hydraulic press is not the solution for every problem. Its design comes with inherent compromises.

Speed vs. Power

Hydraulic presses deliver exceptional force, but they are generally slower than their mechanical counterparts. The time it takes for the fluid to move and build pressure means cycle times are longer, which can be a limitation in high-speed, high-volume production lines.

Complexity and Maintenance

A hydraulic system involves pumps, valves, pistons, seals, and hydraulic fluid. This complexity introduces more potential points of failure and requires regular maintenance to prevent leaks and ensure consistent pressure.

Application-Specific Design

A press designed for crushing cars is fundamentally different from one used to prepare a 13mm KBr pellet in a lab. Industrial presses are massive, heavy-duty machines, while laboratory presses are small, precise instruments. There is no one-size-fits-all solution, and the design must be tailored to the specific task.

Making the Right Choice for Your Goal

The utility of a hydraulic press is defined entirely by its intended application.

- If your primary focus is large-scale production: A hydraulic press is essential for forming, stamping, and molding strong metal or composite parts where immense, controlled force is the priority.

- If your primary focus is scientific research or quality control: A laboratory press is an indispensable tool for preparing consistent samples for analysis and precisely testing material properties.

- If your primary focus is fundamental engineering: The hydraulic press serves as a perfect real-world example of how a principle of fluid dynamics is harnessed to multiply force.

Ultimately, the hydraulic press demonstrates how a fundamental law of physics can be harnessed to shape, test, and analyze the world around us.

Summary Table:

| Primary Use | Key Function | Typical Application |

|---|---|---|

| Industrial Manufacturing | Shaping & Forming | Stamping car parts, forging metals, molding composites |

| Laboratory Analysis | Sample Preparation | Creating uniform pellets for FTIR/XRF spectroscopy |

| Material Testing | Destructive Testing | Verifying compressive strength and failure points |

Need precise force for your lab or production line? KINTEK specializes in hydraulic press solutions for both industrial manufacturing and laboratory sample preparation. Whether you need to form metal components or prepare perfect samples for spectroscopic analysis, our expertise ensures you get the right equipment for your specific task. Contact our experts today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy