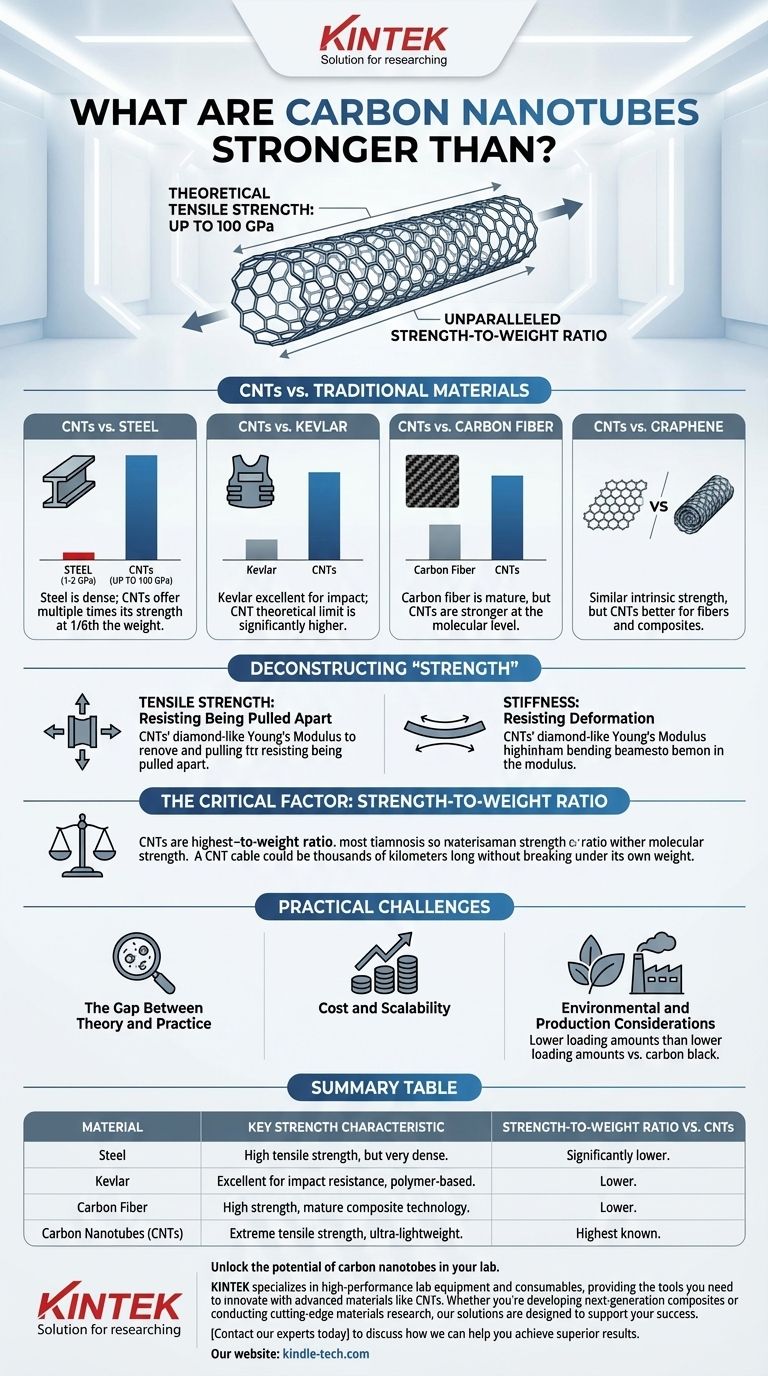

On a theoretical basis, a single carbon nanotube is stronger than nearly any material known to man. It possesses a tensile strength estimated to be up to 100 times greater than the strongest steel alloys, all while being about one-sixth of the weight. This extraordinary strength also surpasses that of other high-performance materials like Kevlar and conventional carbon fiber.

The true value of carbon nanotubes is not just their absolute strength, but their unparalleled strength-to-weight ratio. This combination of extreme durability and low density is what makes them a revolutionary material, promising performance far beyond traditional options.

Deconstructing "Strength": What Does It Really Mean?

When we say a material is "strong," we are often referring to several distinct physical properties. Understanding these is key to appreciating why carbon nanotubes (CNTs) are so remarkable.

Tensile Strength: Resisting Being Pulled Apart

Tensile strength measures a material's ability to withstand being stretched or pulled before it breaks. This is where CNTs exhibit their most famous characteristic.

Due to the powerful covalent bonds between their carbon atoms, individual CNTs have a theoretical tensile strength that can exceed 100 gigapascals (GPa). This is an order of magnitude higher than high-strength steel alloys, which typically fall in the 1-2 GPa range.

Stiffness: Resisting Deformation

Stiffness, measured by Young's Modulus, describes a material's resistance to being bent or deformed. A stiffer material will deform less under the same load.

Carbon nanotubes are exceptionally stiff, with a Young's Modulus comparable to that of diamond and significantly higher than steel. This means they can bear immense loads without changing their shape.

The Critical Factor: Strength-to-Weight Ratio

For most engineering applications, from aerospace to automotive, absolute strength is less important than strength for a given weight.

This is where CNTs have no rival. Because their density is so low (similar to graphite), their strength-to-weight ratio is the highest of any known material. A cable made of CNTs could theoretically be thousands of kilometers long before breaking under its own weight.

Head-to-Head: CNTs vs. Traditional Materials

To put this in context, let's compare CNTs to other well-known materials.

Carbon Nanotubes vs. Steel

While steel is the backbone of modern construction, it is incredibly dense. CNTs offer a profound advantage by providing multiples of steel's strength at a fraction of its weight.

Carbon Nanotubes vs. Kevlar

Kevlar is a polymer famous for its use in bulletproof vests. While it has an excellent strength-to-weight ratio, the theoretical limit for CNTs is significantly higher, promising a new generation of lightweight armor and composites.

Carbon Nanotubes vs. Other Carbon Forms

Compared to conventional carbon fiber, CNTs are fundamentally stronger at the molecular level. However, carbon fiber is a mature technology, making it more practical for large-scale applications today.

Compared to graphene (a single sheet of carbon atoms), CNTs (a rolled-up sheet) exhibit similar intrinsic strength but have different structural properties that make them more suitable for creating fibers and reinforcing composites.

Understanding the Trade-offs and Practical Challenges

The incredible properties described above often refer to a flawless, individual nanotube in a laboratory setting. Translating this potential to real-world, large-scale materials involves significant hurdles.

The Gap Between Theory and Practice

The primary challenge is creating bulk materials (like a thread or sheet) that retain the perfect strength of individual nanotubes. Defects, impurities, and the inability to perfectly align trillions of tubes significantly reduce the final strength of the macro-material.

Cost and Scalability

Producing high-purity, long carbon nanotubes remains an expensive and complex process. This cost is a major barrier to their widespread adoption in many industries, though prices are steadily decreasing as production methods improve.

Environmental and Production Considerations

While production itself can be energy-intensive, CNTs can offer a better lifecycle footprint in certain applications. When used as an additive in composites, they require much lower loading amounts than alternatives like carbon black.

The production of other advanced materials, like graphene, can also face challenges with high energy use and harsh chemicals. This makes the specific environmental trade-off for CNTs highly dependent on the application and manufacturing process.

Making the Right Choice for Your Application

Choosing a material requires balancing theoretical performance with practical reality.

- If your primary focus is ultimate theoretical strength for research or a niche application: Carbon nanotubes represent the absolute peak of material science potential.

- If your primary focus is a practical, cost-effective strength improvement today: Advanced steel alloys or conventional carbon fiber are more mature and accessible technologies for large structures.

- If your primary focus is creating high-performance composites with a lower environmental load: CNTs present a compelling case over traditional additives like carbon black due to their efficiency.

Ultimately, understanding carbon nanotubes means appreciating the difference between their flawless theoretical potential and the practical, cost-driven reality of engineering today.

Summary Table:

| Material | Key Strength Characteristic | Strength-to-Weight Ratio vs. CNTs |

|---|---|---|

| Steel | High tensile strength, but very dense | Significantly lower |

| Kevlar | Excellent for impact resistance, polymer-based | Lower |

| Carbon Fiber | High strength, mature composite technology | Lower |

| Carbon Nanotubes (CNTs) | Extreme tensile strength, ultra-lightweight | Highest known |

Unlock the potential of carbon nanotubes in your lab.

KINTEK specializes in high-performance lab equipment and consumables, providing the tools you need to innovate with advanced materials like CNTs. Whether you're developing next-generation composites or conducting cutting-edge materials research, our solutions are designed to support your success.

Contact our experts today to discuss how we can help you achieve superior results.

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the temperature resistance of graphite? Unlocking Its High-Temp Potential in Your Lab

- What is the maximum working temperature of graphite? Unlock High-Temp Performance with the Right Atmosphere

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- What is the thermal conductivity of graphite at high temperatures? A Guide to Thermal Management in Extreme Heat

- Is graphite good in high temperature? Unlocking Its Extreme Heat Potential