At its core, the primary disadvantage of an induction furnace is its complete lack of refining capacity. Unlike other furnace types, it cannot remove impurities from the charge material, meaning the quality of the metal you put in directly dictates the quality of the metal you get out. This fundamental limitation creates several significant operational constraints.

An induction furnace is a highly precise and efficient melting tool, not a refining vessel. Its main drawbacks stem from its inability to purify metal, requiring high-quality, clean raw materials and making it inflexible for certain operational schedules.

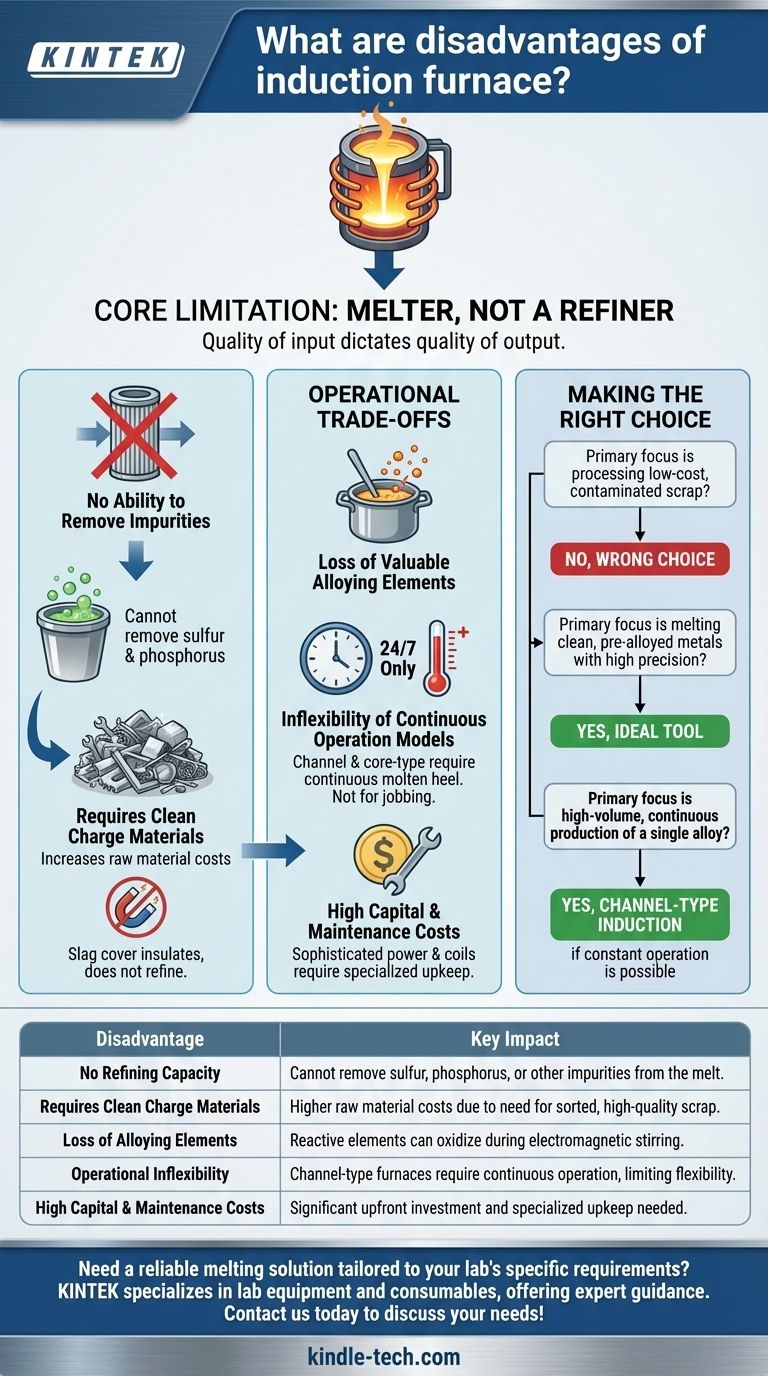

The Core Limitation: An Induction Furnace is a Melter, Not a Refiner

The clean, contained, and flameless nature of induction heating is its greatest strength, but it is also the source of its primary weakness. It lacks the vigorous chemical reactions needed for purification.

No Ability to Remove Impurities

An induction furnace cannot remove undesirable elements like sulfur and phosphorus from the melt. There is no mechanism to facilitate the chemical reactions that draw these contaminants out of the metal and into a slag layer.

This means if you charge the furnace with scrap metal containing high levels of impurities, the final product will also contain those impurities.

The Critical Need for Clean Charge Materials

As a direct consequence, induction furnaces demand a supply of clean, well-sorted charge materials of a known chemical composition. The scrap must be free of excessive rust, oil, dirt, and other non-metallic contaminants.

This requirement often increases the cost of raw materials compared to operations using furnaces, like an Electric Arc Furnace (EAF), that can handle lower-grade, less expensive scrap.

Limited Slag Functionality

While a slag cover can be used in an induction furnace, its role is primarily to insulate the melt, prevent heat loss, and reduce gas absorption. It does not perform the active chemical refining seen in other furnace types.

The gentle stirring action of the induction field is not sufficient to promote the intense slag-metal interaction required for purification.

Understanding the Operational Trade-offs

Beyond the inability to refine, several other practical disadvantages arise that influence the furnace's suitability for a given application.

Loss of Valuable Alloying Elements

While induction furnaces generally cause less overall metal loss (oxidation) than fuel-fired or arc furnaces, a subtle issue remains. The electromagnetic stirring continuously brings metal to the surface, where highly reactive alloying elements can still oxidize and be lost.

This requires careful monitoring of the melt chemistry and the potential need to re-add expensive alloys just before pouring to meet specifications, adding a layer of process control and cost.

Inflexibility of Continuous Operation Models

Certain designs, particularly channel and core-type induction furnaces, are extremely energy-efficient but operate like a transformer where a loop of molten metal acts as the secondary coil.

This design requires that a molten "heel" be maintained at all times. They cannot be easily shut down or cooled, making them suitable only for continuous, 24/7 operations with very few alloy changes. This rigidity makes them a poor choice for jobbing foundries that run intermittently or handle diverse materials.

High Capital and Maintenance Costs

The sophisticated power supplies, capacitors, and water-cooled copper coils represent a significant upfront investment. While highly reliable, these systems require specialized knowledge for maintenance and repair. The refractory lining also requires periodic replacement, which can lead to operational downtime.

Making the Right Choice for Your Operation

Choosing a furnace technology requires aligning its capabilities with your operational goals. The "disadvantages" of an induction furnace are only disadvantages if they conflict with your primary objective.

- If your primary focus is processing low-cost, contaminated scrap: An induction furnace is the wrong choice, as it cannot refine the material to a higher quality.

- If your primary focus is melting clean, pre-alloyed metals with high precision and minimal contamination: The induction furnace is the ideal tool, as its "disadvantages" are irrelevant to this goal.

- If your primary focus is high-volume, continuous production of a single alloy: A channel-type induction furnace offers unmatched efficiency, provided you can accommodate its need for constant operation.

Understanding these limitations is the key to leveraging the induction furnace's unparalleled precision and efficiency for the right application.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| No Refining Capacity | Cannot remove sulfur, phosphorus, or other impurities from the melt. |

| Requires Clean Charge Materials | Higher raw material costs due to need for sorted, high-quality scrap. |

| Loss of Alloying Elements | Reactive elements can oxidize during electromagnetic stirring. |

| Operational Inflexibility | Channel-type furnaces require continuous operation, limiting flexibility. |

| High Capital & Maintenance Costs | Significant upfront investment and specialized upkeep needed. |

Need a reliable melting solution tailored to your lab's specific requirements? KINTEK specializes in lab equipment and consumables, offering expert guidance to help you choose the right furnace technology for your application. Whether you're melting clean alloys or need flexible operational schedules, our team can provide the ideal equipment to enhance your lab's efficiency and precision. Contact us today to discuss your needs and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the process of vacuum quenching? Achieve Superior Hardness with a Pristine Surface Finish

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering