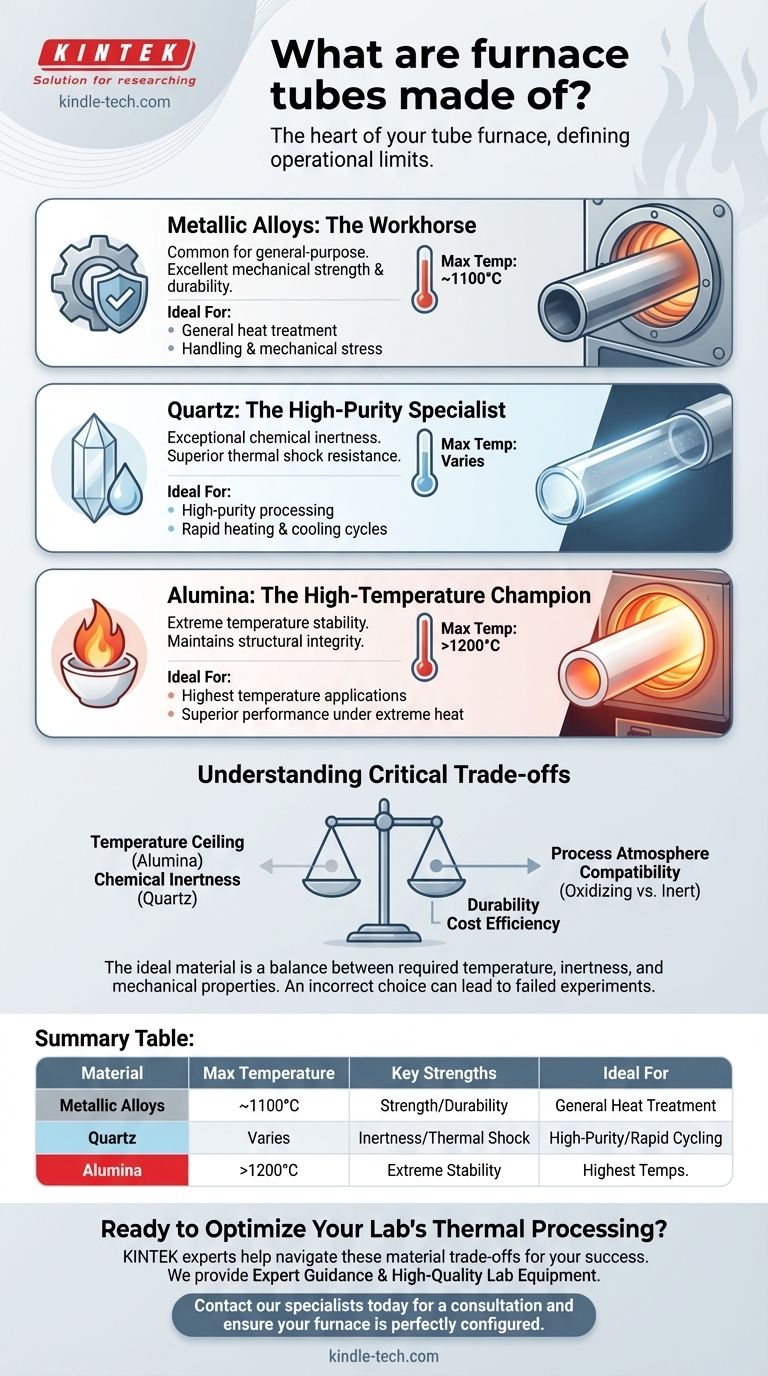

At their core, furnace process tubes are most commonly made from one of three material families: metallic alloys like stainless steel, high-purity quartz, or advanced ceramics like alumina. The specific material is chosen based on the furnace's maximum temperature, the chemical atmosphere required for the process, and the material being heated.

The selection of a furnace tube material is not about finding the "best" one, but about making a critical engineering trade-off. The ideal material for your application will always be a balance between required temperature resistance, chemical inertness, and mechanical durability.

Why Tube Material Governs Furnace Capability

The process tube is the heart of a tube furnace. It's the chamber that contains both your sample and the controlled atmosphere, while also being directly exposed to the furnace's heating elements.

Its material composition is therefore the primary factor that dictates the furnace's operational limits and applications.

Metallic Alloys: The Workhorse

Materials like stainless steel and other heat-resistant alloys are a common choice for general-purpose applications.

They offer excellent mechanical strength and are less prone to cracking from handling or mechanical stress compared to ceramics. These are often used in furnaces operating at temperatures up to approximately 1100°C.

Quartz: The High-Purity Specialist

Quartz (specifically fused silica) is used when purity and thermal shock resistance are paramount. It is exceptionally inert, meaning it won't react with or contaminate the materials being processed.

Its low thermal expansion coefficient allows it to withstand rapid temperature changes without cracking, making it ideal for processes requiring fast heating and cooling cycles.

Alumina: The High-Temperature Champion

For the highest temperature applications (typically >1200°C), alumina is the material of choice. As a high-purity ceramic, it has an extremely high melting point and maintains its structural integrity at temperatures where metals would fail.

Furnace linings and insulation often use alumina fibers for the same reason—its superior performance under extreme heat.

Understanding the Trade-offs

Choosing a tube material involves navigating a series of critical trade-offs. An incorrect choice can lead to failed experiments, damaged equipment, or contaminated samples.

Temperature Ceiling vs. Durability

While alumina tubes can reach the highest temperatures, they are brittle and must be handled with care. Metallic tubes are far more durable and resistant to mechanical shock but have a significantly lower maximum operating temperature.

Chemical Inertness vs. Cost

Quartz offers the best chemical purity for sensitive processes, but it can be more expensive and less robust than some alloys. While many alloys are stable, they can sometimes react with specific atmospheres or samples at elevated temperatures.

Process Atmosphere Compatibility

The tube material must be compatible with the process gas. For example, some metallic alloys may oxidize in an air atmosphere at high temperatures, requiring the use of an inert gas like argon or nitrogen. Quartz and alumina are stable in both oxidizing and inert atmospheres.

Selecting the Right Tube for Your Application

Your choice should be driven by the specific demands of your work.

- If your primary focus is general heat treatment below 1100°C: A stainless steel or heat-resistant alloy tube offers the best balance of performance, durability, and cost.

- If your primary focus is high-purity processing or requires rapid temperature changes: A quartz tube is the ideal choice due to its chemical inertness and excellent thermal shock resistance.

- If your primary focus is achieving the highest possible temperatures (above 1200°C): An alumina ceramic tube is the only suitable option for its superior stability under extreme heat.

Understanding these core material properties empowers you to select a furnace that is not just adequate, but perfectly suited to your specific technical goals.

Summary Table:

| Material | Max Temperature | Key Strengths | Ideal For |

|---|---|---|---|

| Metallic Alloys | Up to ~1100°C | Mechanical strength, durability | General-purpose heat treatment |

| Quartz | Varies | Chemical inertness, thermal shock resistance | High-purity processing, rapid cycling |

| Alumina | >1200°C | Extreme temperature stability | Highest temperature applications |

Ready to Optimize Your Lab's Thermal Processing?

Choosing the right furnace tube is critical for your experiment's success and equipment longevity. The experts at KINTEK are here to help you navigate these material trade-offs.

We provide:

- Expert Guidance: Our team will help you select the perfect tube material—be it stainless steel, quartz, or alumina—based on your specific temperature, atmosphere, and purity requirements.

- High-Quality Lab Equipment: KINTEK specializes in furnaces and consumables, ensuring you get reliable performance for all your laboratory needs.

Don't leave your results to chance. Contact our specialists today for a consultation and ensure your furnace is perfectly configured for your application.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the function of graphite seals in high-temperature tubular reactors? Ensure Hermetic Atmospheric Integrity

- Why use a three-zone tubular furnace for hydrolysis reactors? Master Precision Thermal Gradients for Purity

- What specific conditions does a tubular furnace provide for the reduction of Pt catalysts? Optimize Your Catalyst Performance

- What is the role of a tube furnace in the preparation of LiNbO3 coatings on NCM? Optimize Cathode Interface Stability

- In what way does a high-precision tube furnace facilitate the regulation of aluminum gradients? Master Cathode Synthesis

- Why are quartz sealing tubes and argon protection required during annealing of Fe-Mn-Cr alloys? Ensure Alloy Integrity

- What role does a tube atmosphere furnace play in UDA catalysts? Optimize Your Catalyst Synthesis with Precision

- What role does a vertical tube furnace play in alloy corrosion tests? Master Long-Term Atmospheric Control