In manufacturing, presses are machines that use immense force to fundamentally change the shape of a material. They are the workhorses of production, responsible for everything from stamping car body panels and forging engine components to extruding plastic pipes and forming molds.

The core function of a manufacturing press is to apply a controlled, powerful force to a workpiece, precisely shaping, cutting, or forming it between a tool (a die) and a bed.

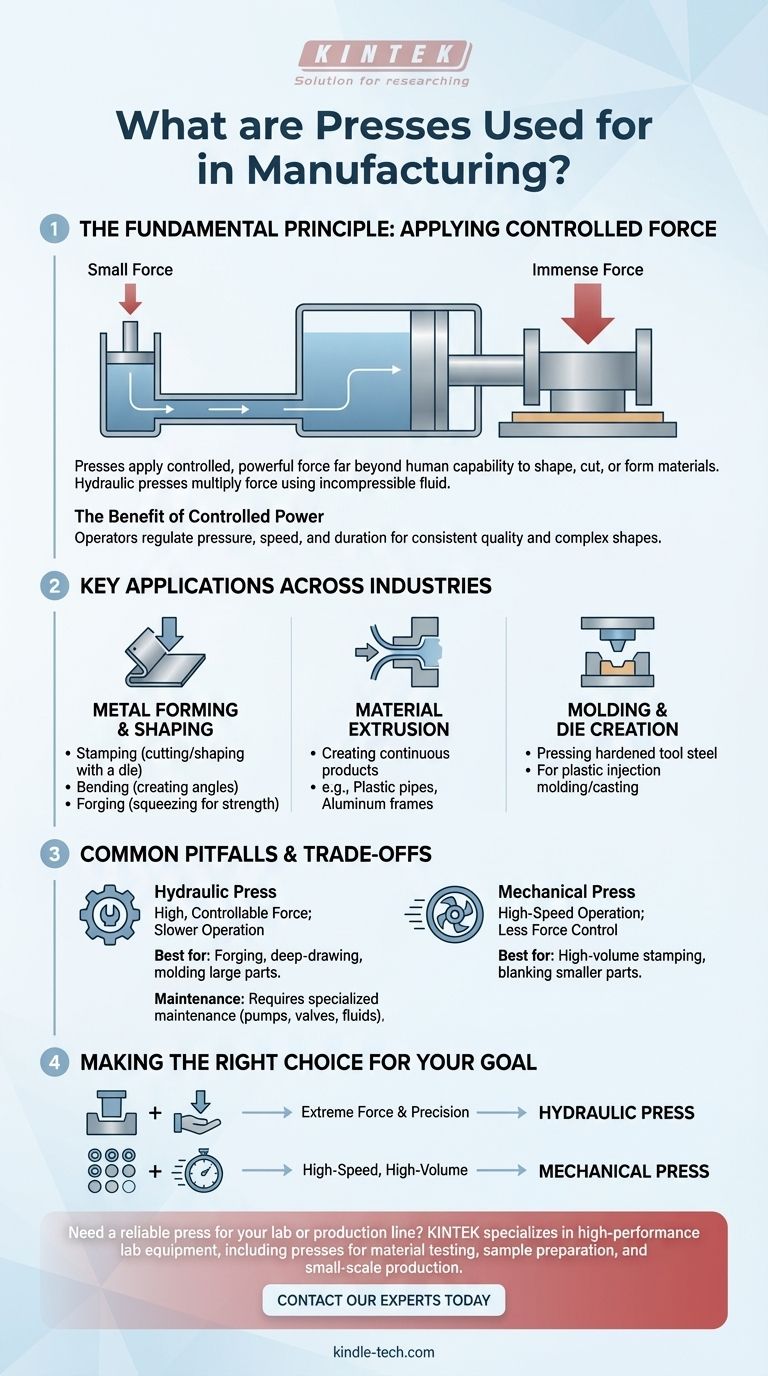

The Fundamental Principle: Applying Controlled Force

The defining characteristic of any press is its ability to generate and apply force far beyond human capability. This allows manufacturers to work with robust materials like steel and aluminum with high precision and repeatability.

How a Hydraulic Press Works

Many industrial presses are hydraulic. They operate on a simple principle: a small amount of force applied to a small piston in a sealed system of incompressible fluid (like oil) generates a significantly larger force on a bigger piston. This force multiplication is what allows a hydraulic press to exert thousands of tons of pressure.

The Benefit of Controlled Power

This massive force isn't just brute strength; it's highly controllable. Operators can precisely regulate the pressure, speed, and duration of the press stroke, ensuring consistent quality and complex shapes for every part produced.

Key Applications Across Industries

The ability to precisely shape materials with force makes presses indispensable in nearly every manufacturing sector. Their applications are diverse and critical to modern production lines.

Metal Forming and Shaping

This is the most common use for presses. It includes stamping, where a sheet of metal is cut or shaped by a die; bending, which creates angles in metal plates; and forging, where a metal billet is squeezed under extreme pressure to form a dense, strong part like a crankshaft.

Material Extrusion

Presses are used to force material through a shaped die to create a long, continuous product. A key example is the extrusion of plastic pipes or aluminum window frames, where raw material is pushed through a die to create the final profile.

Molding and Die Creation

Beyond making final products, presses are also used to create the molds and dies that other manufacturing processes rely on. This involves pressing hardened tool steel into a specific shape, which will then be used for tasks like plastic injection molding or casting.

Common Pitfalls and Trade-offs

While powerful, choosing and operating a press involves understanding its limitations. The type of press chosen has significant implications for production speed, cost, and capability.

Speed vs. Power

Hydraulic presses offer immense, controllable force but are often slower than their counterparts. Mechanical presses, which use a flywheel and crank system, are much faster and ideal for high-volume stamping but typically offer less force and stroke control.

Maintenance and Complexity

Hydraulic systems, with their pumps, valves, and fluids, require specialized maintenance. Leaks can be a point of failure, leading to downtime and environmental concerns if not managed properly.

Making the Right Choice for Your Goal

The best type of press is entirely dependent on the specific manufacturing task.

- If your primary focus is extreme force and precision for large parts: A hydraulic press is the superior choice for applications like deep-drawing, forging, or molding.

- If your primary focus is high-speed, high-volume production of smaller parts: A mechanical press is ideal for rapid stamping and blanking operations.

Ultimately, presses are the foundational tools that translate raw materials into the finished goods that shape our world.

Summary Table:

| Press Type | Key Characteristic | Primary Application |

|---|---|---|

| Hydraulic Press | High, controllable force; slower operation | Forging, deep-drawing, molding large parts |

| Mechanical Press | High-speed operation; less force control | High-volume stamping, blanking of smaller parts |

Need a reliable press for your lab or production line?

KINTEK specializes in high-performance lab equipment, including presses for material testing, sample preparation, and small-scale production. Whether you need precise force control for R&D or a durable solution for consistent results, our expertise ensures you get the right equipment for your specific laboratory needs.

Contact our experts today to find the perfect press for your application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the factors that affect pellet quality? Master KBr Pellet Prep for Flawless FTIR Results

- What is metal forming with a hydraulic press? Harnessing Immense Force for Precision Shaping

- How is a laboratory hydraulic press utilized for nanoporous material precursors? Optimize Density & Uniformity

- What is forging in hydraulic press? Master Controlled Metal Forming with Sustained Pressure

- How does a laboratory hydraulic press improve regenerated leather quality? Enhance Strength and Density

- How much weight can a hydraulic press do? Understand Force vs. Weight for Safe Operation

- Why is press forging used for large forging? For Superior Internal Integrity in Massive Components

- What are the three applications of a hydraulic press? From Metal Forming to Lab Precision