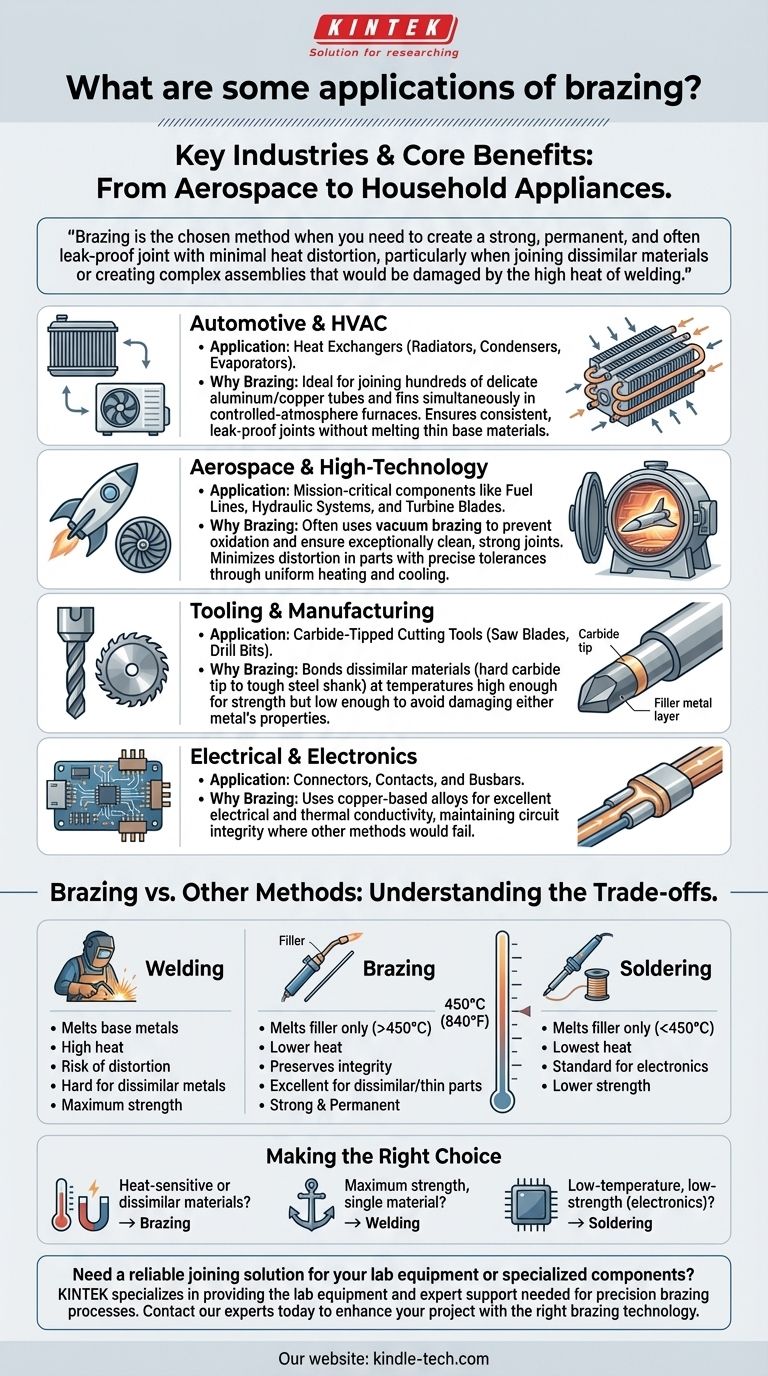

From aerospace components to common household appliances, brazing is a critical joining technology used to manufacture a vast array of products. Its key applications include creating the complex tube-and-fin assemblies in heat exchangers (like automotive radiators and air conditioners), joining hard carbide tips to steel cutting tools, assembling sensitive aerospace parts, and connecting pipes and valves in plumbing and HVAC systems.

Brazing is the chosen method when you need to create a strong, permanent, and often leak-proof joint with minimal heat distortion, particularly when joining dissimilar materials or creating complex assemblies that would be damaged by the high heat of welding.

Where Brazing Excels: A Look at Key Industries

Brazing is not a one-size-fits-all solution. It is selected for specific engineering problems where its unique advantages over welding or soldering are paramount.

Automotive and HVAC

In automotive and air conditioning systems, heat exchangers like radiators, evaporators, and condensers are essential. These parts consist of hundreds or thousands of small, delicate joints between aluminum or copper tubes and fins.

Brazing is ideal here because it can join all these connections simultaneously in a controlled-atmosphere furnace. This mass-production capability, often using automatic brazing machines, ensures consistent, leak-proof joints without melting the thin base materials.

Aerospace and High-Technology

The aerospace industry relies on brazing for mission-critical components. Large, complex assemblies like fuel lines, hydraulic systems, and turbine blade components are often joined using vacuum brazing.

This process takes place in a vacuum, which prevents oxidation and ensures an exceptionally clean, strong joint. Most importantly, it provides uniform heating and cooling, which minimizes the risk of distortion in parts that must meet extremely precise tolerances.

Tooling and Manufacturing

Many cutting tools, from saw blades to drill bits, consist of a tough steel body and an extremely hard cutting edge made of a material like tungsten carbide. Welding these two dissimilar materials is often impractical.

Brazing provides the perfect solution. It allows the carbide tip to be bonded to the steel shank at a temperature high enough to create a strong joint but low enough to avoid damaging the properties of either metal.

Electrical and Electronics

Components that must carry an electrical current, such as connectors, contacts, and busbars, benefit from brazing.

Using a filler metal like a copper-based alloy ensures the finished joint has excellent electrical and thermal conductivity. This maintains the integrity of the electrical circuit, which would be compromised by a less conductive joining method.

Understanding the Trade-offs: Brazing vs. Other Methods

To truly understand brazing's applications, you must know when not to use it. Its value is defined by its relationship to other common joining processes.

Brazing vs. Welding

Welding involves melting the base metals themselves to fuse them together, creating a very strong, homogenous joint. However, this high heat can warp and distort the parts, and it is difficult to weld dissimilar metals.

Brazing uses a lower temperature that only melts a filler metal, not the base metals. This preserves the integrity of the parts and is the superior choice for joining dissimilar metals or thin-walled components.

Brazing vs. Soldering

Both brazing and soldering use a filler metal to join parts without melting them. The key distinction is temperature.

Technically, any process using a filler metal that melts below 450°C (840°F) is soldering. Any process above that temperature is brazing. This higher temperature gives brazed joints significantly greater strength and temperature resistance than soldered joints.

Making the Right Choice for Your Project

Selecting the correct joining method depends entirely on your project's specific requirements for strength, materials, and thermal sensitivity.

- If your primary focus is joining heat-sensitive or dissimilar materials: Brazing is the ideal solution, as it creates a strong bond with minimal thermal impact on the base metals.

- If your primary focus is maximum strength in a single-material assembly: Welding is often the superior choice, as it fuses the base metals into one continuous part.

- If your primary focus is a low-temperature, low-strength application like electronics: Soldering is the correct and established industry standard.

By understanding these core principles, you can select the right joining method not by habit, but by precise engineering requirements.

Summary Table:

| Industry | Key Application | Why Brazing is Used |

|---|---|---|

| Automotive & HVAC | Heat exchangers (radiators, condensers) | Mass-production of leak-proof joints on thin, delicate materials |

| Aerospace | Turbine blades, fuel lines, hydraulic systems | Clean, strong joints with minimal distortion in vacuum furnaces |

| Tooling | Carbide-tipped cutting tools (drill bits, saw blades) | Bonds dissimilar metals (carbide to steel) without damaging them |

| Electrical | Connectors, busbars, contacts | Maintains excellent electrical and thermal conductivity in the joint |

Need a reliable joining solution for your lab equipment or specialized components?

Brazing is the ideal method for creating strong, permanent bonds in heat-sensitive or complex assemblies. At KINTEK, we specialize in providing the lab equipment and expert support needed for precision brazing processes. Whether you're developing custom components or maintaining critical systems, our solutions ensure integrity and performance.

Contact our experts today to discuss how we can enhance your project with the right brazing technology.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is oxidation in brazing? How to prevent it for strong, durable joints