A muffle furnace provides unparalleled process control and purity by isolating the heated material from the heating source itself. Its key advantages include exceptional temperature uniformity and the prevention of sample contamination, making it ideal for sensitive applications. However, these benefits come at the cost of slower heating times and limited access to the interior during operation.

A muffle furnace is not simply a high-temperature oven; it is a controlled environment. Its fundamental value lies in trading the raw speed of direct heating for the absolute purity and thermal uniformity required for sensitive scientific and industrial processes.

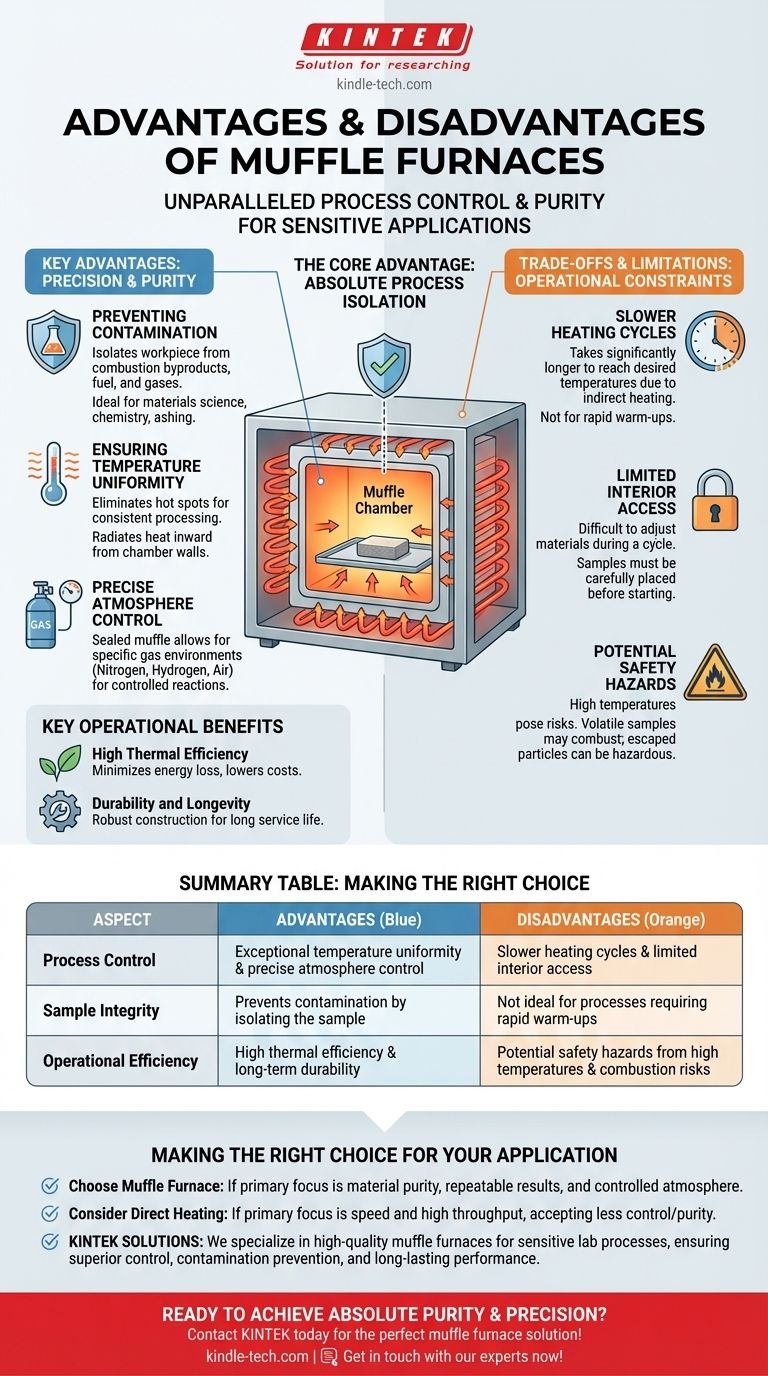

The Core Advantage: Absolute Process Isolation

The defining characteristic of a muffle furnace is its inner chamber, or "muffle," which separates the workload from the heating elements. This design is the source of its most significant benefits.

Preventing Contamination

The muffle acts as a physical barrier, protecting the workpiece from combustion byproducts, fuel, and other gases from the heating source. This isolation is critical in applications like materials science, chemistry, and ashing, where any external influence could contaminate the sample and invalidate the results.

Ensuring Temperature Uniformity

By heating the chamber walls, which then radiate heat inward, the furnace provides a highly uniform and stable thermal environment. This eliminates the hot spots and uneven temperatures often found in direct-heating furnaces, ensuring that the entire sample is processed consistently.

Precise Atmosphere Control

The sealed nature of the muffle allows for precise control over the internal atmosphere. The chamber can be filled with specific gases like nitrogen, hydrogen, or air to facilitate or prevent certain chemical reactions during the heating process, a crucial feature for advanced materials engineering.

Key Operational Benefits

Beyond its core function of isolation, the modern muffle furnace is engineered for efficiency and reliability in demanding environments.

High Thermal Efficiency

Muffle furnaces are designed with high-quality insulation and heat-resistant materials. This minimizes energy loss, retains heat effectively, and contributes to lower operational costs over the long term.

Durability and Longevity

Their robust construction ensures a long service life even under continuous high-temperature use. This reliability makes them a practical and cost-effective investment for laboratories and industrial settings.

Understanding the Trade-offs and Limitations

While powerful, the design of a muffle furnace introduces several operational constraints that must be considered.

Slower Heating Cycles

Compared to open-flame methods, muffle furnaces take significantly longer to reach the desired temperature. The indirect heating process is inherently slower, making them less ideal for projects that demand rapid warm-ups or high throughput.

Limited Interior Access

The enclosed design makes it difficult to access or adjust materials once a heating cycle has begun. All samples must be carefully placed before starting the process, which limits its flexibility for dynamic experiments.

Potential Safety Hazards

High temperatures present inherent risks. Specific concerns include the potential for volatile samples to combust upon contact with the hot interior. Furthermore, any particles that escape a poorly sealed muffle can pose a hazard to the surrounding area and equipment.

Making the Right Choice for Your Application

Selecting the right heating equipment depends entirely on the priorities of your process.

- If your primary focus is material purity and repeatable results: The isolation and superior temperature uniformity of a muffle furnace are essential.

- If your primary focus is speed and high throughput: You may need to explore direct heating methods, accepting the potential for less temperature control and sample contamination.

- If your primary focus is controlled atmosphere processing: A muffle furnace is one of the most effective and reliable tools for this specific requirement.

Ultimately, choosing a muffle furnace is a strategic decision to prioritize control and precision over operational speed.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Process Control | Exceptional temperature uniformity & precise atmosphere control | Slower heating cycles & limited interior access during operation |

| Sample Integrity | Prevents contamination by isolating the sample | Not ideal for processes requiring rapid warm-ups |

| Operational Efficiency | High thermal efficiency & long-term durability | Potential safety hazards from high temperatures & combustion risks |

Ready to achieve absolute purity and precision in your lab processes?

At KINTEK, we specialize in providing high-quality muffle furnaces and other lab equipment designed for sensitive applications in materials science, chemistry, and ashing. Our solutions ensure superior temperature control, contamination prevention, and long-lasting performance to meet your specific laboratory needs.

Contact us today to find the perfect muffle furnace for your application and enhance your lab's efficiency and reliability. Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a muffle furnace and its uses? Achieve Contamination-Free High-Temperature Processing

- What is the function of muffle furnace in food industry? Ensure Accurate Ash Determination for Quality Control

- What is a muffle furnace used to measure? Unlock Precise Sample Analysis with High-Temp Heating

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating

- What is the difference between a muffle furnace and an oven? Choose the Right High-Temperature Tool