In essence, Hot Isostatic Pressing (HIP) is a manufacturing process that uses high temperature and uniform, high-pressure gas to eliminate internal porosity and improve the material properties of metals, ceramics, and composites. It functions as a healing step, densifying components to near 100% theoretical density, which dramatically enhances their mechanical performance and reliability.

The decision to use Hot Isostatic Pressing is not about incremental improvement; it is a strategic choice for applications where ultimate material integrity is non-negotiable. It trades higher cost and process complexity for unparalleled density, fatigue life, and performance in mission-critical components.

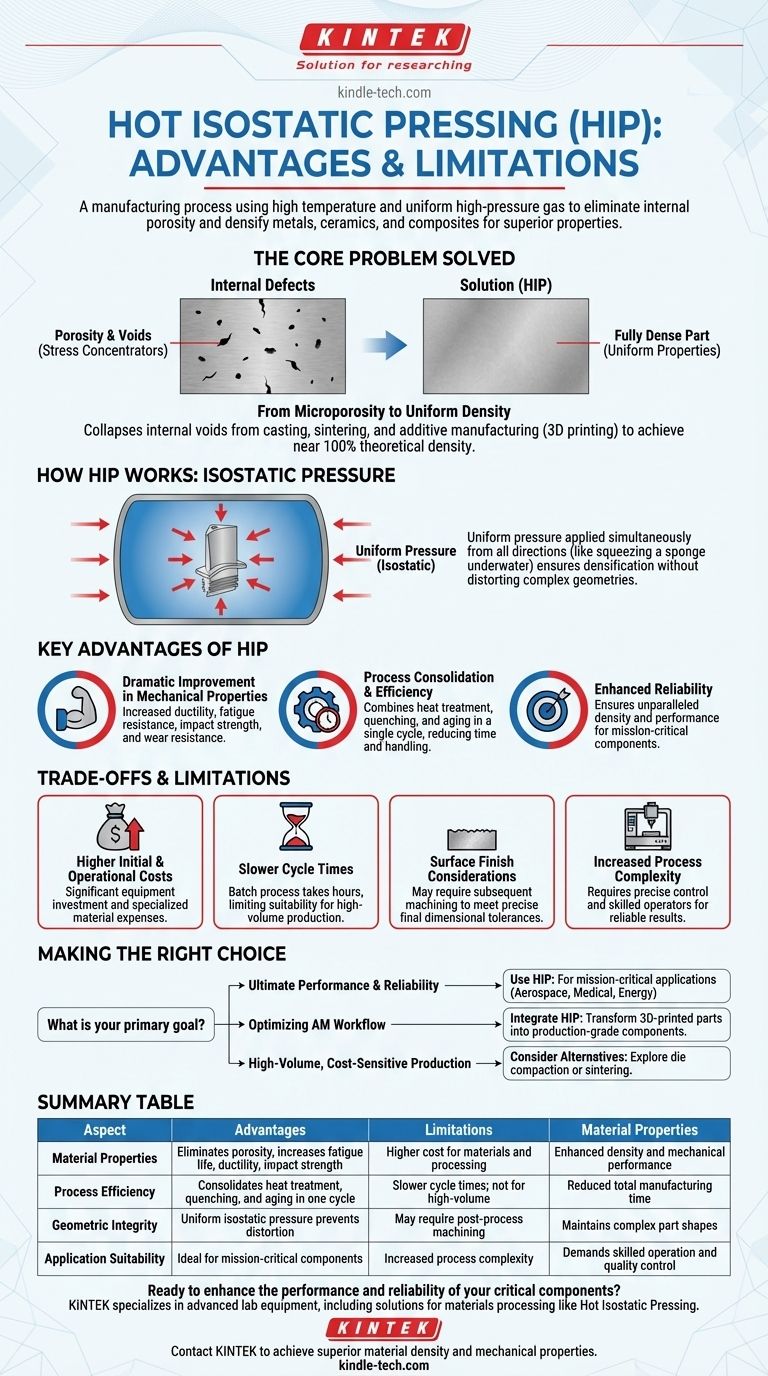

The Core Problem HIP Solves: Internal Defects

Parts produced through casting, sintering, or additive manufacturing often contain microscopic internal voids or defects. These flaws act as stress concentrators, becoming the initiation points for cracks and ultimate part failure.

From Microporosity to Uniform Density

In castings, microporosity is caused by gas entrapment or shrinkage during solidification. HIP subjects the component to a temperature high enough to make it pliable and a gas pressure that exceeds its yield strength, physically collapsing these internal voids.

The result is a fully dense part with a uniform grain structure and significantly improved mechanical properties.

Healing Additively Manufactured Parts

Additive manufacturing (3D printing) builds parts layer by layer, which can lead to incomplete fusion between layers or trapped gas porosity. HIP is exceptionally effective at bonding these layers together and closing internal pores, transforming a near-net-shape part into a fully consolidated, high-performance component.

The "How": Isostatic Pressure Explained

The key is the "isostatic" nature of the pressure. Unlike uniaxial pressing, which compresses a part from one or two directions and creates internal friction, HIP applies uniform pressure from all directions simultaneously.

Imagine squeezing a sponge underwater—the pressure is equal on all surfaces. This ensures the part densifies uniformly without distorting its overall geometry, regardless of its complexity.

Key Advantages of HIP Integration

Integrating HIP into a manufacturing workflow offers benefits that go far beyond simply removing pores. It is a transformative process that enhances both the part itself and the production timeline.

Dramatic Improvement in Mechanical Properties

By eliminating internal defects, HIP provides a significant and measurable boost to a material's performance. This includes increased ductility, fatigue resistance, impact strength, and wear resistance.

This allows engineers to design components that are lighter, stronger, and more reliable under extreme operating conditions.

Process Consolidation and Efficiency

Modern HIP systems can combine multiple thermal processing steps into a single cycle. A part can undergo heat treatment, quenching, and aging within the HIP unit itself, immediately after the densification cycle.

This consolidation can drastically reduce total manufacturing time, energy consumption, and material handling, leading to a more efficient overall workflow.

Understanding the Trade-offs and Limitations

While powerful, HIP is not a universal solution. Its benefits must be weighed against its inherent costs and process demands.

Higher Initial and Operational Costs

HIP equipment represents a significant capital investment. Furthermore, the process often requires the use of specialized, high-purity powders or careful pre-processing, which adds to the operational expense.

Slower Cycle Times

Compared to conventional methods like die compaction or extrusion, HIP is a batch process with a slower cycle time. Loading, pressurizing, heating, holding, cooling, and unloading can take several hours, limiting its use for high-volume, low-cost parts.

Surface Finish Considerations

The flexible tooling or container used in some HIP processes can result in a less precise surface finish compared to mechanical pressing. Consequently, critical surfaces often require subsequent machining to meet final dimensional tolerances, adding another step and cost to production.

Increased Process Complexity

Operating a HIP system requires precise control over high pressures, temperatures, and gas atmospheres. This demands skilled operators and robust quality control systems to ensure repeatable and reliable results.

Making the Right Choice for Your Goal

The decision to implement HIP depends entirely on the performance requirements and economic constraints of your component.

- If your primary focus is ultimate performance and reliability: Use HIP for mission-critical components in aerospace, medical implants, or energy applications where failure could be catastrophic.

- If your primary focus is optimizing an additive manufacturing workflow: Integrate HIP to transform 3D-printed metal parts from near-net-shape prototypes to fully dense, production-grade components.

- If your primary focus is high-volume, cost-sensitive production: Consider alternatives like conventional die compaction or sintering, as the cost and cycle time of HIP may not be justifiable.

Ultimately, leveraging Hot Isostatic Pressing correctly is a strategic decision to invest in material certainty.

Summary Table:

| Aspect | Advantages | Limitations |

|---|---|---|

| Material Properties | Eliminates porosity, increases fatigue life, ductility, and impact strength. | Higher cost for materials and processing. |

| Process Efficiency | Consolidates heat treatment, quenching, and aging into one cycle. | Slower cycle times; not suitable for high-volume production. |

| Geometric Integrity | Uniform isostatic pressure prevents distortion of complex shapes. | May require post-process machining for precise surface finishes. |

| Application Suitability | Ideal for mission-critical components in aerospace, medical, and energy sectors. | Increased process complexity demands skilled operators and robust quality control. |

Ready to enhance the performance and reliability of your critical components? KINTEK specializes in advanced lab equipment and consumables, including solutions for materials processing like Hot Isostatic Pressing. Our expertise helps laboratories and manufacturers achieve superior material density and mechanical properties. Contact us today to discuss how we can support your mission-critical applications with precision and reliability.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process