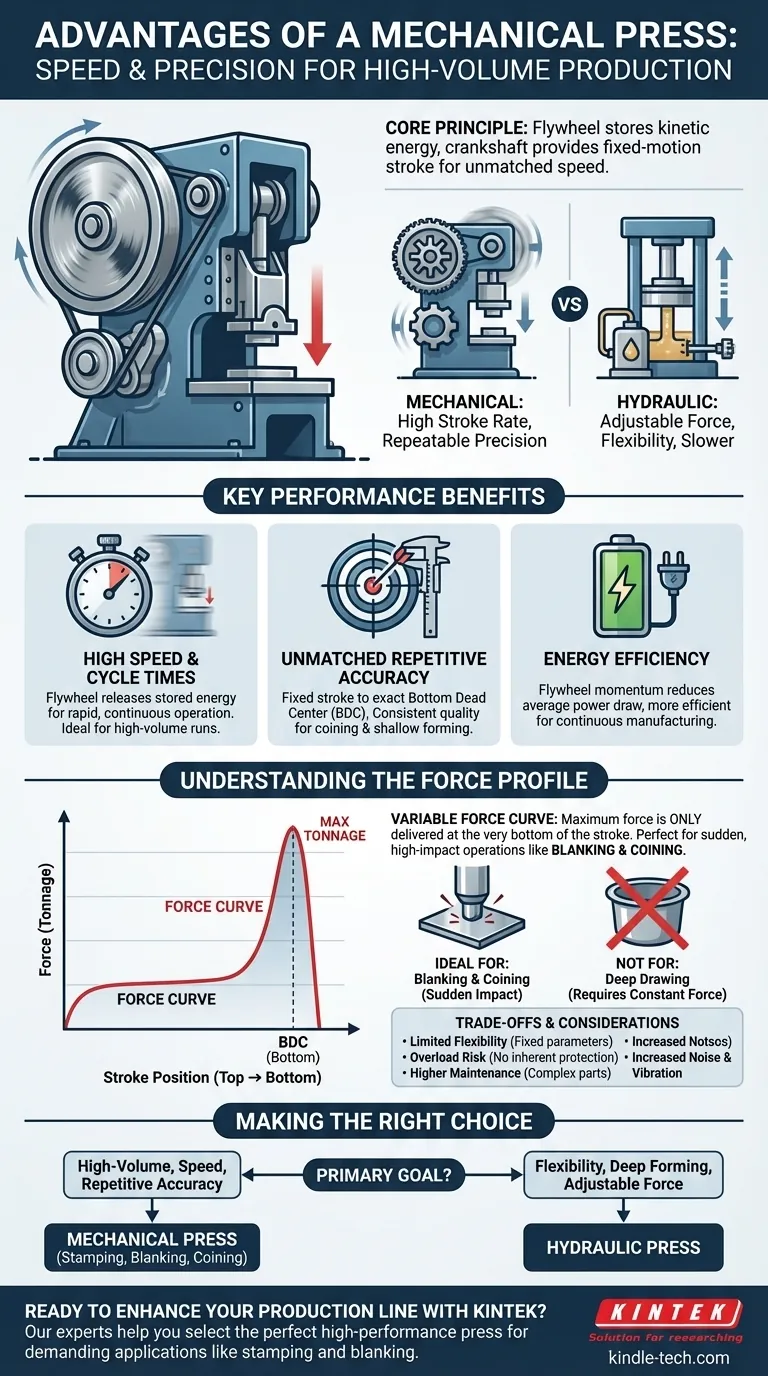

At its core, a mechanical press is designed for speed and repeatable precision. While hydraulic presses offer flexibility, the primary advantages of a mechanical press are its high stroke rate, exceptional accuracy at the bottom of the stroke, and energy efficiency, making it the standard for high-volume stamping, blanking, and coining operations.

The decision between a mechanical and hydraulic press is not about which is universally "better," but which is the correct tool for the job. A mechanical press trades the adjustable force of a hydraulic system for unmatched speed and consistency in repetitive manufacturing tasks.

The Mechanics of Speed and Precision

The design of a mechanical press is fundamentally different from a hydraulic one, giving it a distinct performance profile. Its advantages are a direct result of its core components.

The Crankshaft and Flywheel Principle

A mechanical press uses a motor to spin a heavy flywheel, which stores a massive amount of kinetic energy. When the press is activated, a clutch connects the flywheel to a crankshaft, which drives the ram down in a fixed-motion stroke, much like the piston in an engine.

This design allows for the rapid release of stored energy, enabling significantly faster cycle times than a hydraulic system, which must pump fluid to generate force.

Unmatched Repetitive Accuracy

The most critical advantage for many applications is its positional accuracy. Because the stroke length is determined by the fixed mechanical geometry of the crankshaft, the ram descends to the exact same point—known as bottom dead center (BDC)—on every single cycle.

This extreme repeatability is essential for operations like coining and shallow forming, where precise material compression is required to achieve consistent part quality across millions of cycles.

Energy Efficiency in High-Volume Runs

For continuous, high-volume production, a mechanical press is often more energy-efficient. The motor's primary job is to keep the flywheel at speed, drawing less power on average compared to a hydraulic pump that may need to run continuously to maintain pressure. The energy for the actual work comes from the flywheel's stored momentum.

Understanding the Force Profile

A common misconception is that a press's rated tonnage is available at all times. For a mechanical press, this is not true, and understanding its force curve is key to using it correctly.

A Variable Force Curve

A mechanical press only delivers its maximum rated tonnage at the very bottom of the stroke. The force available is significantly lower at the top and middle of the stroke.

This is a direct result of the leverage provided by the crankshaft. As the crank approaches the BDC position, the mechanical advantage skyrockets, allowing it to generate immense force over a very short distance.

Why This Matters for Application

This force profile makes a mechanical press ideal for jobs that require a sudden, massive impact at the end of the stroke, such as blanking (punching shapes out of metal) or coining.

However, it is poorly suited for deep-drawing operations, which require consistent force over a long distance to form a part without tearing it.

Understanding the Trade-offs

The advantages of a mechanical press come with clear limitations. Choosing the wrong type of press for an application can lead to damaged equipment, poor part quality, and inefficiency.

Limited Flexibility and Control

Unlike a hydraulic press where stroke length, speed, and pressure can be easily adjusted, these parameters are largely fixed in a mechanical press. Changing the stroke requires significant mechanical reconfiguration.

Overload Risk

A mechanical press has no inherent overload protection. If the force required exceeds the press's capacity, it will attempt to complete its stroke, which can lead to catastrophic failure of the dies or the press itself. Hydraulic systems, by contrast, use pressure relief valves to prevent damage.

Higher Maintenance Complexity

While robust, mechanical presses have more complex moving parts, such as clutches, brakes, and bearings. Maintaining these components requires specialized knowledge and can be more involved than servicing the simpler valving and seals of a hydraulic system.

Increased Noise and Vibration

The high-speed impact of the ram in a mechanical press generates significantly more noise and vibration than the smoother, controlled motion of a hydraulic press.

Making the Right Choice for Your Goal

Selecting the correct press technology requires a clear understanding of your primary manufacturing objective.

- If your primary focus is high-volume production and speed: The repetitive accuracy and high stroke rate of a mechanical press make it the superior choice for stamping, blanking, or coining.

- If your primary focus is flexibility and deep forming: A hydraulic press is better suited due to its full, constant tonnage throughout the stroke and easily adjustable controls.

- If your primary focus is lower initial cost and simple force control: A hydraulic press often presents a lower barrier to entry and is more forgiving for applications with variable force requirements.

Ultimately, choosing the right press is about matching the machine's fundamental strengths to the specific demands of your application.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| High Speed | Flywheel-driven crankshaft for rapid cycle times | High-volume production runs |

| Repetitive Accuracy | Fixed stroke to bottom dead center (BDC) | Coining, shallow forming, and stamping |

| Energy Efficiency | Flywheel stores kinetic energy, reducing average power draw | Continuous, high-volume manufacturing |

| Force at BDC | Maximum tonnage delivered at the bottom of the stroke | Blanking and operations requiring sudden, high impact |

Ready to enhance your production line with the speed and precision of a mechanical press? KINTEK specializes in high-performance lab and industrial equipment, including mechanical presses designed for demanding applications like stamping and blanking. Our experts will help you select the perfect press to maximize your efficiency and output. Contact us today to discuss your specific needs and discover how KINTEK can power your success!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What can XRF identify? Discover the Elements in Your Materials with Precision

- How is a hydraulic press so strong? Unlocking the Power of Force Multiplication

- What types of hydraulic press systems are used for research? Discover Pellet, Hot, and Isostatic Solutions

- How does a laboratory hydraulic press ensure the accuracy of test results? Master Precision Specimen Preparation

- What are the major parts of a press? A Guide to the Core Components of a Hydraulic Press

- What material is a hydraulic press made out of? Built with High-Strength Steel for Maximum Force

- What is a pellet mill used for? Transforming Powders into Precise Samples and Components

- What are the maintenance required for the hydraulic system? A Proactive Guide to Prevent Costly Failures