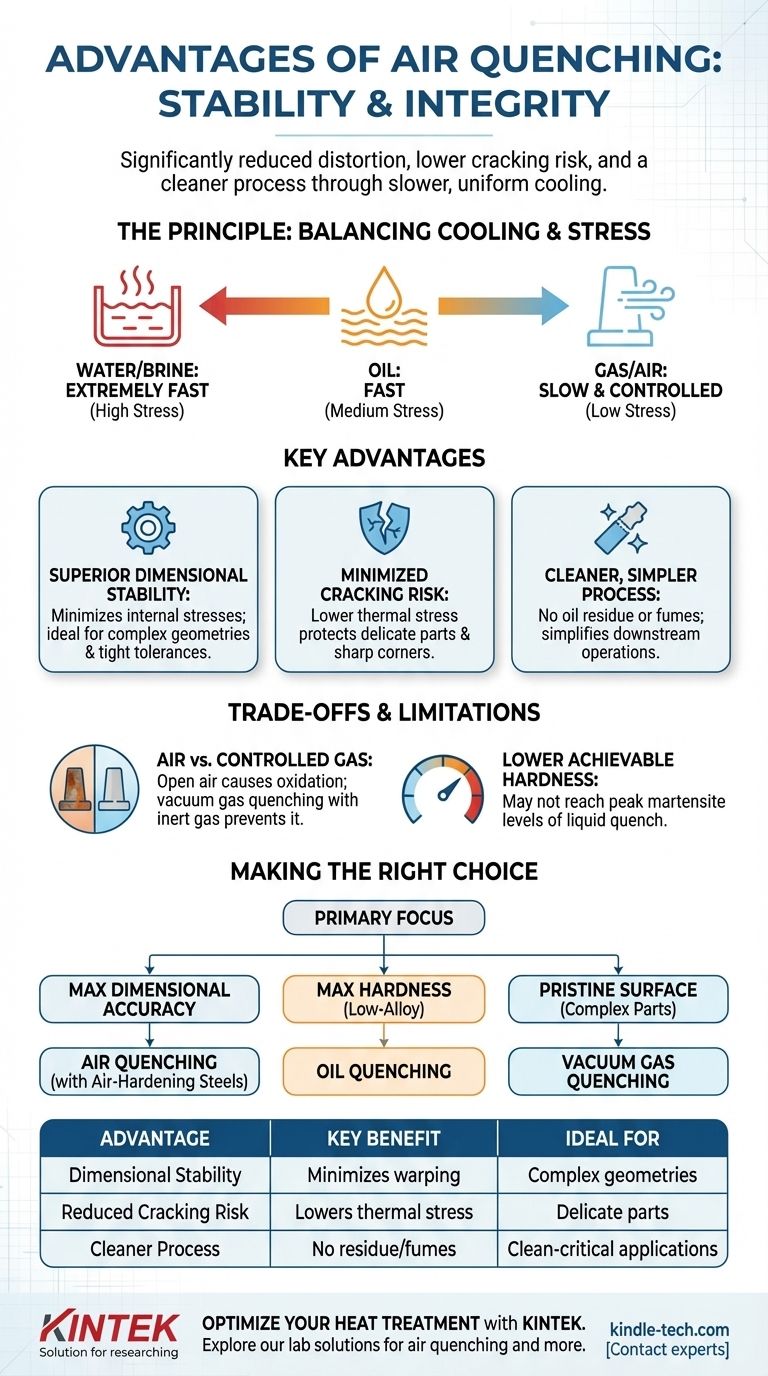

In short, the primary advantages of air quenching are significantly reduced part distortion, a lower risk of cracking, and a cleaner process compared to liquid-based methods. This is achieved by cooling the material more slowly and uniformly, which minimizes the internal stresses that cause these defects.

The decision to use air quenching is fundamentally a trade-off. You are choosing to prioritize dimensional stability and part integrity over achieving the absolute maximum hardness possible, a choice that is only suitable for specific high-alloy steels.

The Principle: Balancing Cooling Rate and Stress

To understand the advantages of air quenching, you must first understand the core goal of quenching in heat treatment.

What is Quenching?

Quenching is the process of rapidly cooling a heated metal part to lock in a specific, desirable crystal structure. For steel, this desired structure is typically martensite, which is extremely hard and strong.

The key is that the cooling must be fast enough to prevent the steel from forming softer, less desirable structures.

The Spectrum of Cooling Severity

Different quenching media extract heat at vastly different rates. This creates a spectrum of "quenching severity."

A typical hierarchy from fastest to slowest cooling is:

- Water/Brine: Extremely fast, but creates immense thermal shock.

- Oil: Fast, but gentler than water. The industry standard for many steels.

- Gas/Air: Slow and controlled, creating the least amount of thermal shock.

Why Slower Cooling Reduces Stress

When a part is plunged into a liquid, the surface cools almost instantly while the core remains hot. This massive temperature difference creates powerful internal stresses that can warp the part or even cause it to crack.

Air quenching, by cooling the part much more slowly and uniformly, dramatically reduces this thermal shock. The temperature gradient between the surface and the core is much smaller, minimizing internal stress.

Key Advantages of Air Quenching

The gentler nature of air cooling provides three main benefits, especially when compared to oil or water quenching.

Superior Dimensional Stability

Because it minimizes internal stresses, air quenching is the best method for maintaining a part's precise shape and dimensions. This is critical for complex geometries, thin sections, or parts with very tight tolerances.

Minimized Risk of Cracking

The high thermal stress from liquid quenching can easily crack delicate parts, sharp corners, or certain brittle alloys. Air quenching is a much safer process that makes cracking highly unlikely.

A Cleaner, Simpler Process

Liquid quenching involves managing large tanks of oil or water, which can create fumes, fire hazards, and require post-process cleaning to remove residue. Air quenching is a cleaner process that leaves parts free of oil, simplifying downstream operations.

Understanding the Trade-offs and Limitations

While advantageous, air quenching is not a universal solution. Its effectiveness is limited by critical trade-offs.

The Critical Distinction: Air vs. Controlled Gas

Standard air quenching is done in the open atmosphere. While it reduces distortion, the oxygen in the air will cause some surface oxidation and decarburization (loss of carbon from the surface), which can be undesirable.

This is different from vacuum gas quenching, which uses a sealed furnace filled with an inert gas like nitrogen or argon. This method provides the benefits of slow cooling without causing oxidation, resulting in a bright, clean surface.

Lower Achievable Hardness

The primary drawback of a slow cooling rate is that it may not be fast enough to form 100% martensite. As a result, parts quenched in air may not achieve the same peak hardness as they would if quenched in oil.

Limited to Specific "Air-Hardening" Steels

This limitation is crucial. Only certain types of steel can be hardened effectively with air. These are known as air-hardening steels.

These steels contain high amounts of alloying elements (like chromium, molybdenum, and manganese) that slow down the formation of soft structures. This gives the slow air quench enough time to cool the part past the "nose" of the TTT curve and form martensite. Common tool steels like A2, D2, and H13 are examples of air-hardening grades.

Making the Right Choice for Your Application

Selecting a quenching method requires matching the process to your material and your primary engineering goal.

- If your primary focus is maximum dimensional accuracy and part integrity: Air quenching is the ideal choice, provided you are using an air-hardening grade of steel.

- If your primary focus is achieving maximum hardness in a low-alloy steel: A more severe liquid quench, like oil, is necessary to achieve the required cooling rate.

- If your primary focus is a pristine, oxide-free surface on a complex part: Vacuum gas quenching with an inert gas is the required process.

Ultimately, understanding these trade-offs empowers you to select the quenching method that precisely aligns with your material and design requirements.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Dimensional Stability | Minimizes warping and distortion | Complex geometries, tight tolerances |

| Reduced Cracking Risk | Gentle cooling lowers thermal stress | Delicate parts, sharp corners, brittle alloys |

| Cleaner Process | No oil residue or fumes; simpler workflow | Applications requiring clean, post-process parts |

Need to optimize your heat treatment process for dimensional stability and part integrity?

At KINTEK, we specialize in providing the right lab equipment and consumables for your specific heat treatment challenges. Whether you're working with air-hardening tool steels or exploring vacuum gas quenching for pristine surfaces, our expertise can help you select the perfect solution to enhance your lab's efficiency and ensure the highest quality results.

Contact our experts today to discuss how we can support your laboratory's unique needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the benefits of heat treatment? Enhance Material Strength, Durability, and Performance

- How do you rejuvenate vacuum tubes? A Guide to Restoring Cathode Performance

- Why is a vacuum drying system utilized for PDVB nanoparticle preparation? Preserve Structure and Chemical Activity

- What role does a high-temperature heat treatment furnace play in Alloy 800H preparation? Optimize Surface Diffusion

- What does it mean to sinter metals? A Guide to Solid-State Fusion for Strong, Complex Parts

- How big is the vacuum furnace market? A Multi-Billion Dollar Industry Driven by High-Tech Demand

- What is the vacuum arc remelting process? Producing Ultra-Pure, High-Performance Metal Alloys

- What is the purpose of using a vacuum drying oven for Na3V2(PO4)3 (NVP) electrodes? Ensure Battery Stability