The primary advantages of Spark Plasma Sintering (SPS) revolve around its remarkable speed, lower processing temperatures, and the ability to produce materials with superior density and finer microstructures compared to conventional methods. By directly passing a pulsed DC current through the powder and die, SPS combines rapid heating with mechanical pressure to consolidate materials in minutes rather than the hours required by traditional furnaces.

Spark Plasma Sintering is not merely an incremental improvement over conventional sintering; it is a transformative technology. Its core advantage lies in using a unique combination of heat, pressure, and electrical fields to consolidate materials so quickly that detrimental effects like grain growth are suppressed, unlocking new possibilities for advanced material design.

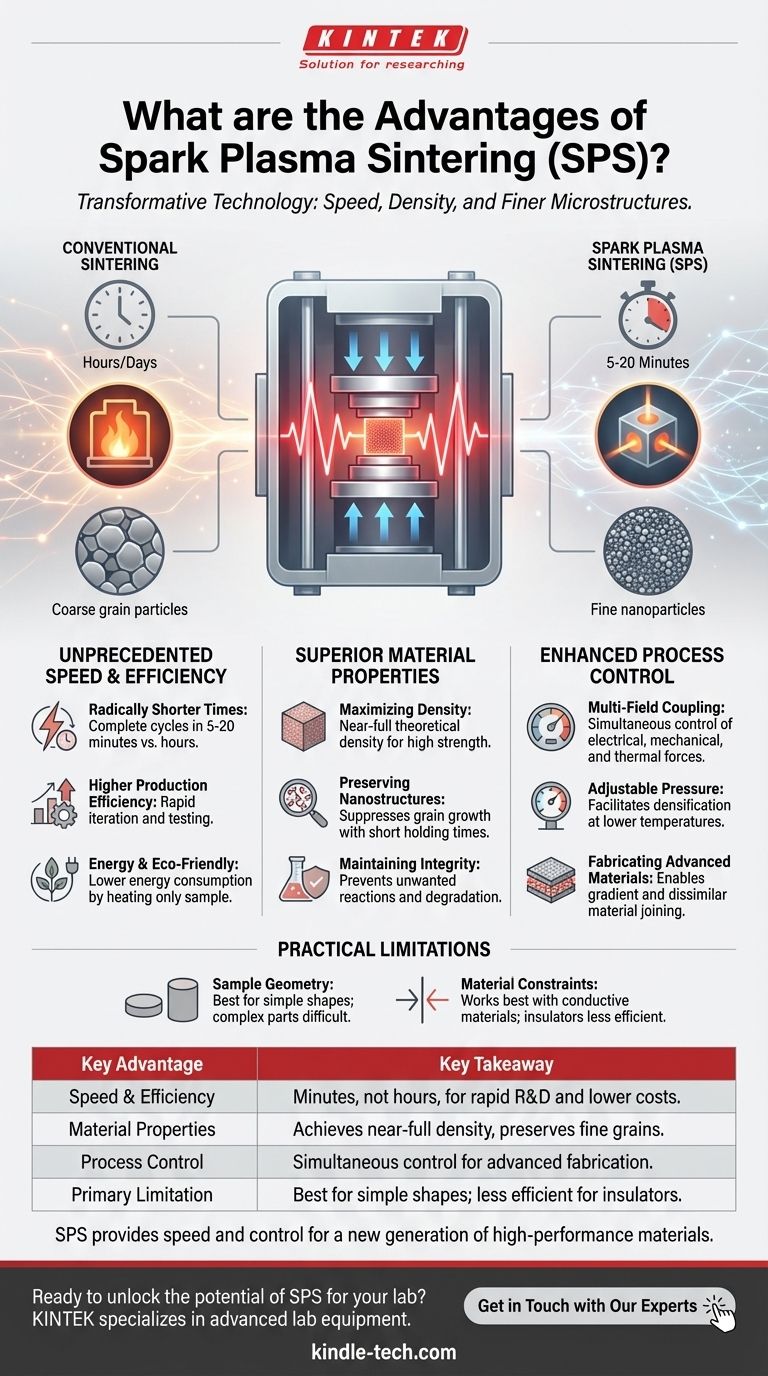

The Core Advantage: Unprecedented Speed and Efficiency

Conventional sintering is often a slow, energy-intensive process. SPS fundamentally changes this timeline by using a more direct and efficient heating mechanism.

Radically Shorter Sintering Times

The most cited benefit of SPS is its speed. The direct joule heating of the sample and graphite tooling allows for extremely rapid temperature increases, often hundreds of degrees Celsius per minute.

This means a full sintering cycle, which could take many hours or even days in a conventional furnace, can often be completed in 5 to 20 minutes with SPS.

Higher Production Efficiency

This dramatic reduction in processing time directly translates to higher throughput. For research and development, it allows for rapid iteration and testing of new material compositions.

Energy Efficiency and Environmental Friendliness

By heating only the sample and its immediate tooling, rather than an entire large furnace chamber, SPS consumes significantly less energy per cycle. This not only reduces operational costs but also lowers its environmental footprint.

Achieving Superior Material Properties

The speed of SPS is not just for efficiency; it is the key to creating materials with characteristics that are difficult or impossible to achieve through other means.

Maximizing Density

The combination of high pressure and rapid heating is extremely effective at eliminating porosity between powder particles. SPS consistently produces materials with near-full theoretical density, which is critical for maximizing mechanical strength, thermal conductivity, and other performance metrics.

Preserving Nanostructures and Fine Grains

In conventional sintering, prolonged exposure to high temperatures causes small grains to coarsen and grow. This is often undesirable as it can degrade mechanical properties like hardness and strength.

Because the holding time at peak temperature is so short in SPS, it effectively suppresses this grain growth. This makes it the ideal technique for consolidating nanomaterials while preserving their unique nanoscale features and associated properties.

Maintaining Raw Material Integrity

The lower overall sintering temperatures and short duration help to prevent unwanted chemical reactions, phase decomposition, or degradation of the initial raw materials.

Enhanced Process Control and Versatility

SPS provides operators with multiple levers to precisely control the consolidation process, enabling the creation of complex and novel materials.

The Power of Multi-Field Coupling

SPS is a multi-field coupled process, meaning it simultaneously applies and controls electrical, mechanical (pressure), and thermal forces. This high degree of control allows for fine-tuning the sintering process to suit the specific needs of the material.

Adjustable Sintering Pressure

The ability to apply significant mechanical pressure throughout the cycle is a key differentiator from pressureless sintering. This pressure aids in particle rearrangement and plastic deformation, facilitating densification at lower temperatures.

Fabricating Advanced Materials

The precise control offered by SPS makes it uniquely suited for producing advanced materials that are beyond the reach of conventional techniques. This includes gradient materials, where composition changes across the sample, and joining dissimilar materials.

Understanding the Practical Limitations

While powerful, SPS is not a universal solution. It's essential to recognize its trade-offs.

Sample Geometry and Size

The primary limitation is sample geometry. SPS is best suited for producing simple shapes like discs, cylinders, or rectangular bars that can be contained within a graphite die. Complex, near-net-shape parts are generally not feasible.

Furthermore, the size of components is often limited by the press capacity and the size of the vacuum chamber, with most systems geared toward research-scale or small-part production.

Material Constraints

SPS works best with materials that have at least some electrical conductivity. While insulating materials like many ceramics can be sintered, it requires careful die design and can be less efficient than with conductive materials.

Making the Right Choice for Your Goal

SPS is a specialized tool that excels in specific scenarios. Choosing it depends entirely on your material and performance objectives.

- If your primary focus is preserving nanostructures or fine grains: SPS is the clear choice, as its speed prevents the grain growth that plagues slower, conventional methods.

- If your primary focus is achieving maximum density in difficult-to-sinter materials: The combination of pressure and rapid heating makes SPS exceptionally effective for consolidating refractory metals, carbides, and advanced ceramics.

- If your primary focus is rapid material development and prototyping: The short cycle times of SPS allow you to test dozens of compositions or processing parameters in the time it would take to run a single conventional furnace cycle.

Ultimately, Spark Plasma Sintering provides a level of speed and control that enables the creation of a new generation of high-performance materials.

Summary Table:

| Key Advantage | Key Takeaway |

|---|---|

| Speed & Efficiency | Sintering cycles completed in minutes, not hours, for rapid R&D and lower energy costs. |

| Material Properties | Achieves near-full density and preserves fine grains/nanostructures for superior performance. |

| Process Control | Simultaneous control of temperature, pressure, and electrical fields enables advanced material fabrication. |

| Primary Limitation | Best suited for simple shapes (discs, cylinders) and is less efficient for insulating materials. |

Ready to unlock the potential of Spark Plasma Sintering for your lab?

If your research or production depends on creating high-density materials, preserving nanostructures, or accelerating your materials development cycle, KINTEK has the expertise and equipment to help.

We specialize in providing advanced lab equipment and consumables, including solutions for sintering and materials processing. Our team can help you determine if SPS is the right technology to achieve your material performance goals.

Contact us today to discuss your specific application and discover how we can support your laboratory's success.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication

- What are the parameters for spark plasma sintering? Master Speed, Pressure & Temperature Control