In pharmaceutical manufacturing, the primary advantages of a ball mill are its ability to produce exceptionally fine powders, handle toxic substances safely through its enclosed system, and maintain product sterility. This simple yet effective technology is suitable for a wide range of applications, including both wet and dry grinding processes, making it a versatile tool for particle size reduction.

The core value of a ball mill in pharmacy isn't just its grinding power, but its operational simplicity and closed-system design. This design inherently provides the critical benefits of sterility and operator safety, which are often non-negotiable in pharmaceutical settings.

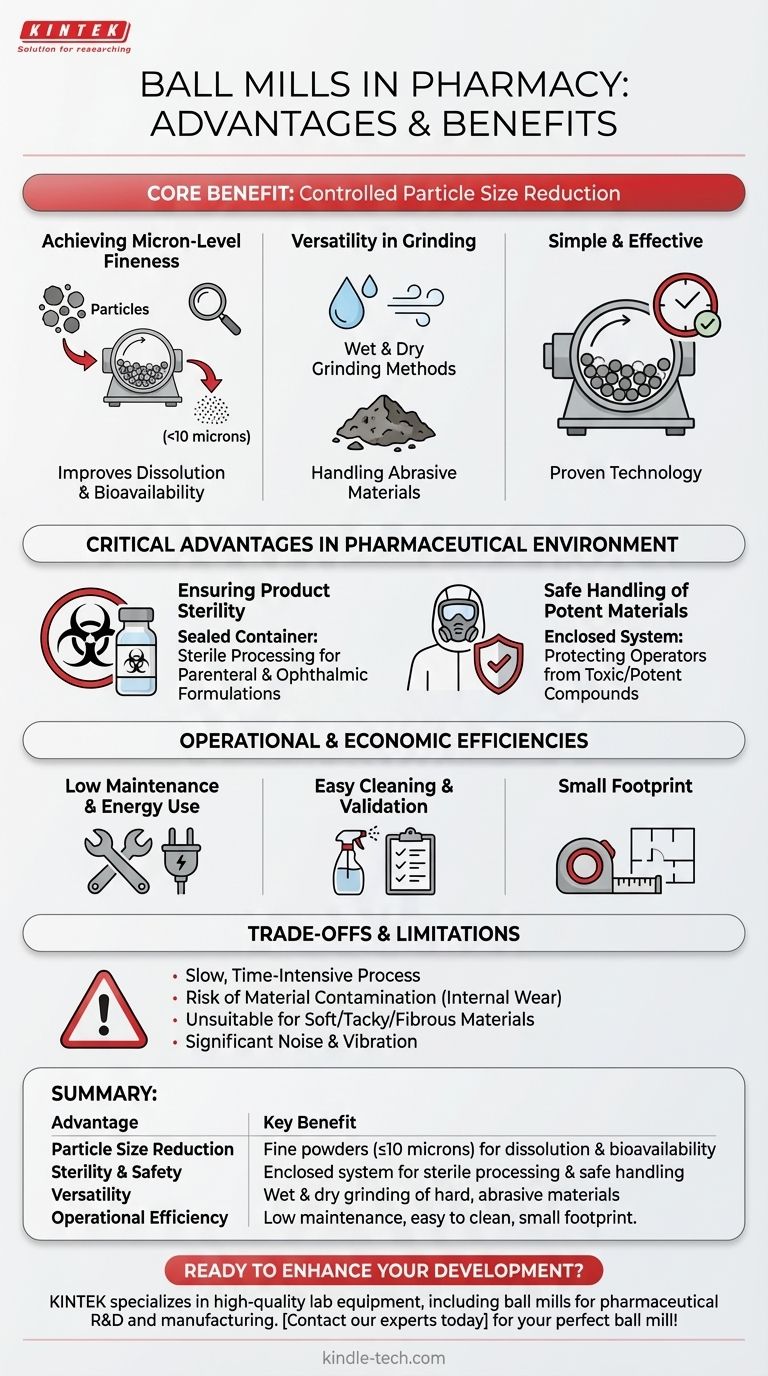

The Core Benefit: Controlled Particle Size Reduction

The fundamental purpose of a ball mill is to reduce the size of solid materials. In pharmacy, the precision and versatility of this process are critical for drug efficacy and manufacturability.

Achieving Micron-Level Fineness

A ball mill excels at producing a very fine powder. It can consistently reduce particle sizes to 10 microns or less.

This level of fineness is crucial for improving the dissolution rate and bioavailability of poorly soluble active pharmaceutical ingredients (APIs).

Versatility in Grinding Processes

The technology is highly adaptable, suitable for both wet and dry grinding methods. This allows formulators to select the best process based on the material's properties and the desired final product characteristics.

Handling Abrasive Materials

Many pharmaceutical compounds and excipients can be hard and abrasive. The ball mill's simple, robust mechanism is highly effective at milling these abrasive materials without excessive wear on the primary equipment.

Critical Advantages in a Pharmaceutical Environment

Beyond simple grinding, the ball mill's design offers specific advantages that are essential for meeting the strict requirements of pharmaceutical production.

Ensuring Product Sterility

Because the grinding takes place in a completely sealed container, a ball mill is ideal for manufacturing sterile products. This is a significant advantage for producing parenteral (injectable) and ophthalmic (eye) formulations, where preventing microbial contamination is paramount.

Safe Handling of Potent Materials

The enclosed system also ensures operator safety when working with highly potent or toxic compounds. It minimizes the risk of airborne powder exposure, protecting personnel and preventing cross-contamination in the facility.

Operational and Economic Efficiencies

While not the fastest technology, the ball mill offers practical benefits that make it an attractive option from an operational and financial perspective.

Low Maintenance and Energy Use

The mechanical design is straightforward, leading to low maintenance costs and reliable operation. Compared to more complex milling technologies, it also tends to have a lower energy consumption.

Ease of Cleaning and Small Footprint

The simple container design makes the ball mill relatively easy to clean and validate between batches. Furthermore, it typically requires minimal installation space, a practical benefit in crowded lab or manufacturing environments.

Understanding the Trade-offs and Limitations

To make an informed decision, you must weigh the advantages against the inherent limitations of the technology. A ball mill is not the right solution for every milling task.

It Is a Slow Process

The primary disadvantage is that ball milling is a slow, time-intensive process. For high-volume manufacturing where speed is critical, other technologies may be more suitable.

Risk of Material Contamination

Continuous impact from the grinding media can cause wear on the internal surface of the mill. This creates a potential risk of product contamination, which must be carefully monitored.

Unsuitability for Certain Materials

Ball mills are ineffective for size reduction of soft, tacky, or fibrous materials. These substances tend to coat the grinding media and the mill interior, preventing efficient milling.

Noise, Vibration, and Scale

The process generates significant noise and vibration, which may require special facility considerations. Additionally, the capacity for single batches is often limited compared to other industrial milling systems.

Making the Right Choice for Your Goal

Selecting a ball mill depends entirely on your specific pharmaceutical objective.

- If your primary focus is sterility and safety: A ball mill is an excellent choice for developing parenteral products or handling highly potent APIs due to its enclosed design.

- If your primary focus is achieving maximum fineness for a difficult API: This technology is highly effective for reducing hard, crystalline materials to the low-micron range to improve bioavailability.

- If your primary focus is process speed and high-volume output: You should evaluate other technologies, as the slow milling time of a ball mill may become a significant bottleneck.

Ultimately, the ball mill remains a foundational technology in pharmacy because it reliably solves core challenges of particle size, sterility, and safety in a single, cost-effective unit.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Particle Size Reduction | Produces fine powders (≤10 microns) for improved dissolution and bioavailability. |

| Sterility & Safety | Enclosed system ensures sterile processing and safe handling of toxic/ potent compounds. |

| Versatility | Suitable for both wet and dry grinding of hard, abrasive materials. |

| Operational Efficiency | Low maintenance, easy to clean/validate, and has a small footprint. |

Ready to enhance your pharmaceutical development with reliable milling solutions?

KINTEK specializes in high-quality lab equipment, including ball mills designed for the precise needs of pharmaceutical R&D and manufacturing. Our expertise ensures you get the right equipment for sterile processing, safe handling of potent APIs, and achieving the fine particle sizes critical for drug efficacy.

Contact our experts today to discuss your specific application and find the perfect ball mill for your laboratory!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Hybrid High Energy Vibratory Ball Mill for Lab Use

People Also Ask

- What are the roles of a vacuum dryer and agate mortar in NZVI treatment? Optimize Your Nanomaterial Reactivity

- What is the difference between a ball mill and a tumbling mill? A Guide to Grinding Equipment Types

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation

- What is the function of a vibratory ball mill in the synthesis of lithium-rich double perovskite precursors? Maximize Reactivity

- What is the function of an agate mortar and pestle in solid-state battery preparation? Ensure High Purity Mixing

- What is the function of an eccentric shaft mixer? Solve Nano-Agglomeration in Composite Powders

- Why is uniform nano-powder grinding necessary for martensitic steel creep resistance? Achieve Structural Integrity

- What is the role of laboratory-grade grinders and sieves in sample prep? Ensure High-Precision Corrosion Analysis