The fundamental advantage of coextrusion is its ability to combine multiple polymers into a single, unified profile during the manufacturing process. This allows for the creation of complex parts that leverage the distinct properties of different materials—such as rigidity, flexibility, or color—in one efficient step, yielding a superior and often more cost-effective product than multi-part assemblies.

Coextrusion moves beyond simple manufacturing; it is a design strategy. It empowers you to engineer a single component with tailored properties in specific areas, unlocking performance characteristics and economic efficiencies that are impossible with single-material extrusion.

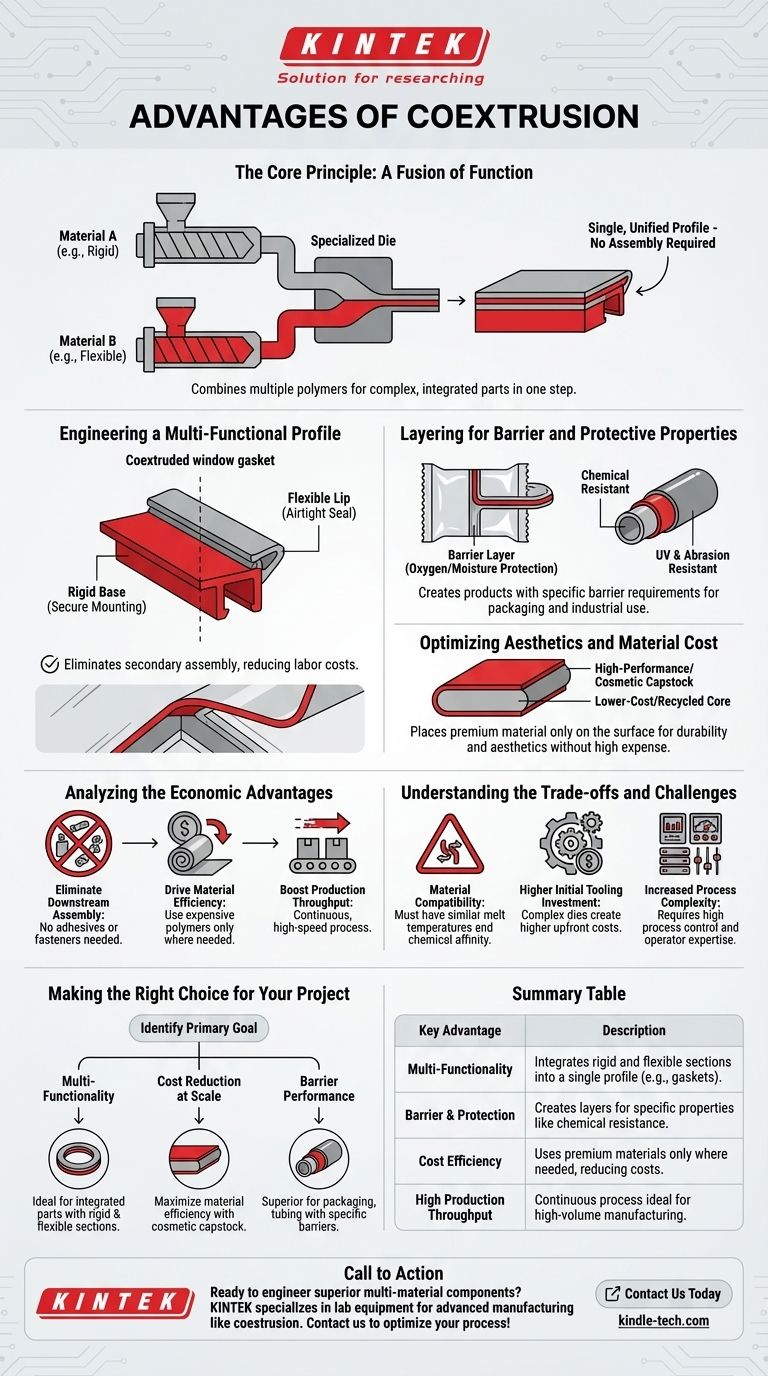

The Core Principle: A Fusion of Function

Coextrusion works by feeding multiple molten polymers from separate extruders into a single, specialized die. Inside the die, these material streams are combined to form a single, multi-layered profile before they cool and solidify.

Engineering a Multi-Functional Profile

The most common advantage is creating a part with both rigid and flexible sections. A classic example is a window gasket or door seal, where a rigid base provides a secure mounting point while a soft, flexible lip creates an airtight or watertight seal.

This eliminates the need to manufacture two separate parts and then assemble them, drastically simplifying the supply chain and reducing labor costs.

Layering for Barrier and Protective Properties

Coextrusion is critical for creating products with specific barrier requirements. In food packaging, one layer might provide structural integrity while a thin inner layer acts as an oxygen or moisture barrier, extending shelf life.

Similarly, in industrial applications like fuel lines, an inner layer can provide chemical resistance to the fuel, while an outer layer provides abrasion and UV resistance.

Optimizing Aesthetics and Material Cost

This process allows you to place a high-performance or cosmetically superior material only where it is needed: on the surface.

A common strategy is to extrude a thin, weather-resistant "capstock" of virgin, UV-stabilized polymer over a thick core made of lower-cost or recycled material. This delivers a durable, aesthetically pleasing finish without the expense of making the entire part from premium material.

Analyzing the Economic Advantages

While the functional benefits are clear, the economic case for coextrusion is often the deciding factor, particularly for high-volume production.

Eliminating Downstream Assembly

The most significant cost saving comes from eliminating secondary assembly operations. By creating a single, integrated component, you remove the need for adhesives, mechanical fasteners, and the labor required to join multiple parts.

Driving Material Efficiency

Coextrusion enables precise material placement. Using expensive polymers only for a thin functional or aesthetic layer allows the bulk of the product to be formed from more economical materials, directly lowering the bill-of-materials cost.

Boosting Production Throughput

As a continuous process, coextrusion can achieve very high production rates. Compared to the stop-and-start nature of injection molding or the multiple steps of fabrication and assembly, it is an extremely efficient method for producing linear profiles.

Understanding the Trade-offs and Challenges

Coextrusion is a powerful technique, but it is not a universal solution. Understanding its limitations is crucial for successful implementation.

The Challenge of Material Compatibility

You cannot combine just any two plastics. For a strong, permanent bond to form, the polymers must have similar melt temperatures and chemical affinity. If they are incompatible, they will delaminate, a failure known as poor adhesion. In some cases, a third, adhesive "tie layer" must be coextruded between them, adding complexity.

Higher Initial Tooling Investment

The dies required for coextrusion are significantly more complex and expensive to design and manufacture than those for single-material extrusion. This higher upfront cost means coextrusion is generally more suitable for high-volume production runs where the tooling cost can be amortized over many units.

Increased Process Complexity

Successfully managing multiple extruders, melt temperatures, and flow rates simultaneously requires a high degree of process control and operator expertise. Maintaining consistent quality and dimensional accuracy is more challenging than in a standard extrusion process.

Making the Right Choice for Your Project

To determine if coextrusion is the correct approach, evaluate your project's primary goal.

- If your primary focus is multi-functionality: Coextrusion is the ideal choice for creating integrated parts with both rigid and flexible sections, such as gaskets, hinges, or bumpers.

- If your primary focus is cost reduction at scale: Use coextrusion to cap a low-cost or recycled core with a thin cosmetic or protective layer, maximizing material efficiency.

- If your primary focus is barrier performance: This process is the superior method for producing multi-layer packaging, tubing, or pipes requiring specific gas, chemical, or moisture barriers.

By understanding its principles and trade-offs, you can leverage coextrusion to engineer innovative, high-performance products that solve complex design challenges efficiently.

Summary Table:

| Key Advantage | Description |

|---|---|

| Multi-Functionality | Integrates rigid and flexible sections into a single profile (e.g., gaskets, seals). |

| Barrier & Protection | Creates layers for specific properties like chemical resistance or UV protection. |

| Cost Efficiency | Uses premium materials only where needed, reducing material and assembly costs. |

| High Production Throughput | Continuous process ideal for high-volume manufacturing of linear profiles. |

Ready to engineer superior multi-material components?

KINTEK specializes in lab equipment and consumables for advanced manufacturing processes like coextrusion. Let our experts help you optimize material selection, process control, and product performance. Contact us today to discuss how we can support your laboratory's innovation and efficiency goals!

Visual Guide

Related Products

- Twin Screw Extruder Plastic Granulation Machine

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Touchscreen Automatic Vacuum Heat Press

People Also Ask

- What machine is used to make pellets? The Complete Guide to Pellet Mills & Production Systems

- What is the function of a stainless steel high-pressure reactor in PMMA/hBN synthesis? Achieve Precise Polymeric Control

- What is the role of high-speed melt mixing equipment? Key to RPE/CSPE Thermoplastic Elastomer Synthesis

- How does extrusion work step by step? A Guide to the Continuous Manufacturing Process

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films