In short, Hot Isostatic Pressing (HIP) elevates Powder Metallurgy (PM) by creating components with near-perfect density. This process eliminates the inherent porosity left by conventional PM, resulting in vastly superior mechanical properties, structural integrity, and overall performance for demanding applications.

The decision between conventional PM and HIP is not about which is universally "better," but about matching the process to the performance requirement. Conventional PM is cost-effective for many applications, while HIP is a necessary investment for parts where failure is not an option.

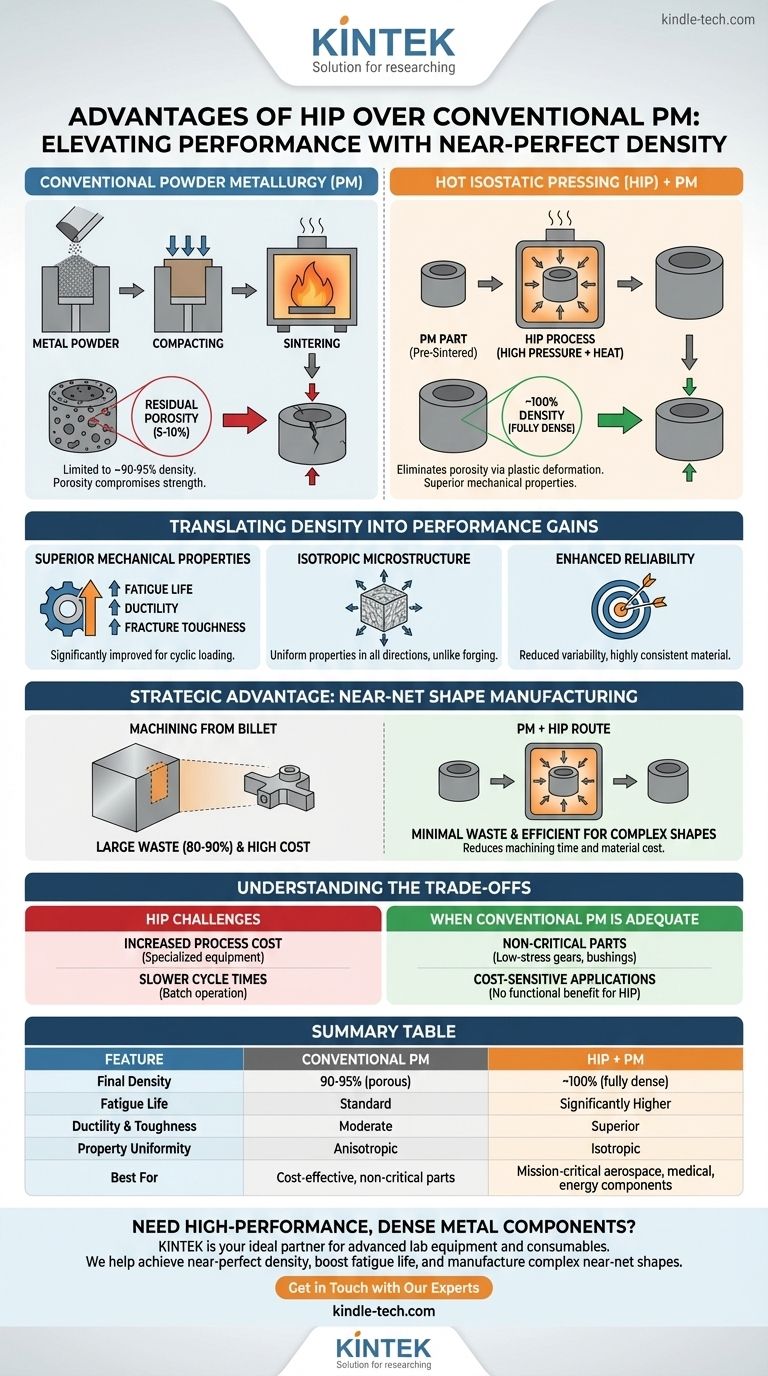

The Fundamental Difference: Eliminating Porosity

The core advantage of HIP stems from its ability to solve the primary weakness of conventional powder metallurgy: residual porosity.

The Limit of Conventional PM

Conventional Powder Metallurgy (PM) involves compacting metal powder in a die and then sintering it. Sintering heats the part to bond the particles together.

Even after sintering, a network of tiny, unavoidable voids, known as porosity, remains within the material. This porosity, often 5-10% by volume, acts as a stress concentrator and compromises the part's ultimate strength.

How HIP Achieves Full Density

Hot Isostatic Pressing (HIP) is typically used as a secondary step after initial sintering. The process subjects the component to extremely high inert gas pressure at an elevated temperature.

This combination of heat and isostatic (uniform from all directions) pressure causes the material to plastically deform on a microscopic level. The voids collapse and metallurgically bond, resulting in a fully dense part with virtually no internal porosity.

Translating Density into Performance Gains

Achieving near 100% density is not just a theoretical benefit; it unlocks tangible and critical improvements in material performance.

Superior Mechanical Properties

By eliminating pores that initiate cracks, HIP dramatically improves key material properties. This includes a significant increase in ductility, fracture toughness, and most importantly, fatigue life. For components subjected to cyclic loading, this is the single most important advantage.

Isotropic and Homogeneous Microstructure

Because the pressure is applied uniformly from all directions, the resulting material properties are isotropic, or the same in all directions. This is a distinct advantage over processes like forging, which can create directional grain flow and anisotropic properties.

Enhanced Reliability and Consistency

The HIP process reduces the variability between parts. By removing the random nature of porosity, it produces a highly consistent material, ensuring that the weakest point of one part is much closer to the weakest point of the next. This increases component reliability and simplifies engineering design.

The Strategic Advantage: Near-Net Shape Manufacturing

Beyond material properties, the combination of PM and HIP offers significant manufacturing advantages over traditional methods like forging or machining from billet.

Reducing Machining Waste and Cost

The PM process can create complex parts very close to their final dimensions, known as near-net shape. Using HIP to densify this shape is far more efficient than starting with a large block of expensive material (like titanium or a superalloy) and machining away 80-90% of it.

Enabling Complex Geometries

HIP allows engineers to design and manufacture intricate shapes with high-performance materials that would be impossible or prohibitively expensive to produce using other methods.

Understanding the Trade-offs

While powerful, HIP is not a universal solution. Its benefits must be weighed against practical considerations.

Increased Process Cost

HIP requires specialized equipment and adds a significant step to the manufacturing chain. This makes it more expensive than conventional PM for a given part. The cost must be justified by the performance requirement.

Slower Cycle Times

The HIP process itself is a batch operation that can take several hours. This adds to the overall production lead time compared to the simpler "press-and-sinter" workflow of conventional PM.

When It's Overkill

For many applications, the mechanical properties offered by conventional PM are perfectly adequate. For low-stress gears, bushings, or structural components in non-critical environments, the added expense of HIP provides no functional benefit.

Making the Right Choice for Your Goal

Selecting the appropriate process requires a clear understanding of your component's end-use and design constraints.

- If your primary focus is cost-sensitive, non-critical parts: Conventional PM offers an excellent balance of properties and economy.

- If your primary focus is ultimate performance and reliability: HIP is the required standard for mission-critical aerospace, medical, and energy applications where fatigue life and structural integrity are paramount.

- If your primary focus is creating complex, high-strength parts while minimizing material waste: The PM + HIP route is often the most cost-effective and capable manufacturing strategy.

By understanding this distinction, you can select the powder metallurgy process that aligns perfectly with your component's performance demands and budget.

Summary Table:

| Feature | Conventional PM | HIP + PM |

|---|---|---|

| Final Density | 90-95% (porous) | ~100% (fully dense) |

| Fatigue Life | Standard | Significantly Higher |

| Ductility & Toughness | Moderate | Superior |

| Property Uniformity | Anisotropic | Isotropic |

| Best For | Cost-effective, non-critical parts | Mission-critical aerospace, medical, energy components |

Need High-Performance, Dense Metal Components?

If your project demands the superior mechanical properties and reliability that only Hot Isostatic Pressing (HIP) can provide, KINTEK is your ideal partner. We specialize in advanced lab equipment and consumables, serving the precise needs of laboratories and manufacturers working with high-performance materials.

We can help you:

- Achieve near-perfect density and eliminate the weaknesses of porosity.

- Boost fatigue life and fracture toughness for mission-critical applications.

- Manufacture complex, near-net shapes efficiently, reducing material waste and cost.

Contact us today to discuss how our expertise can enhance your component performance. Let's find the right powder metallurgy solution for your goals.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is the sinter HIP process? Achieve Near-Perfect Density in a Single Cycle

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What advantages does a warm isostatic press offer over a traditional uniaxial press for Li6PS5Cl electrolyte sheets?

- What is hot isostatic pressing treatment porosity? Achieve 100% Material Density for Critical Components

- What is the HIP process of casting? Transform Castings into High-Performance Components

- What is the purpose of using a high-vacuum diffusion pump system for pre-treating powder capsules in HIP? Avoid PPBs

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance