The primary advantages of Hot Isostatic Pressing (HIP) are its ability to eliminate internal porosity and achieve nearly 100% theoretical density in metal components. This process dramatically improves mechanical properties such as fatigue life, ductility, and wear resistance, while also relieving internal stresses. For parts made via casting or additive manufacturing, HIP heals internal defects and weak layer bonds, creating a uniform, monolithic microstructure with properties that can rival or exceed those of traditionally forged materials.

Hot Isostatic Pressing is not merely a finishing step; it is a transformative process. By applying high heat and uniform gas pressure, it fundamentally closes the internal voids that are the primary source of failure in high-performance components, turning a porous or layered structure into a fully dense, solid part.

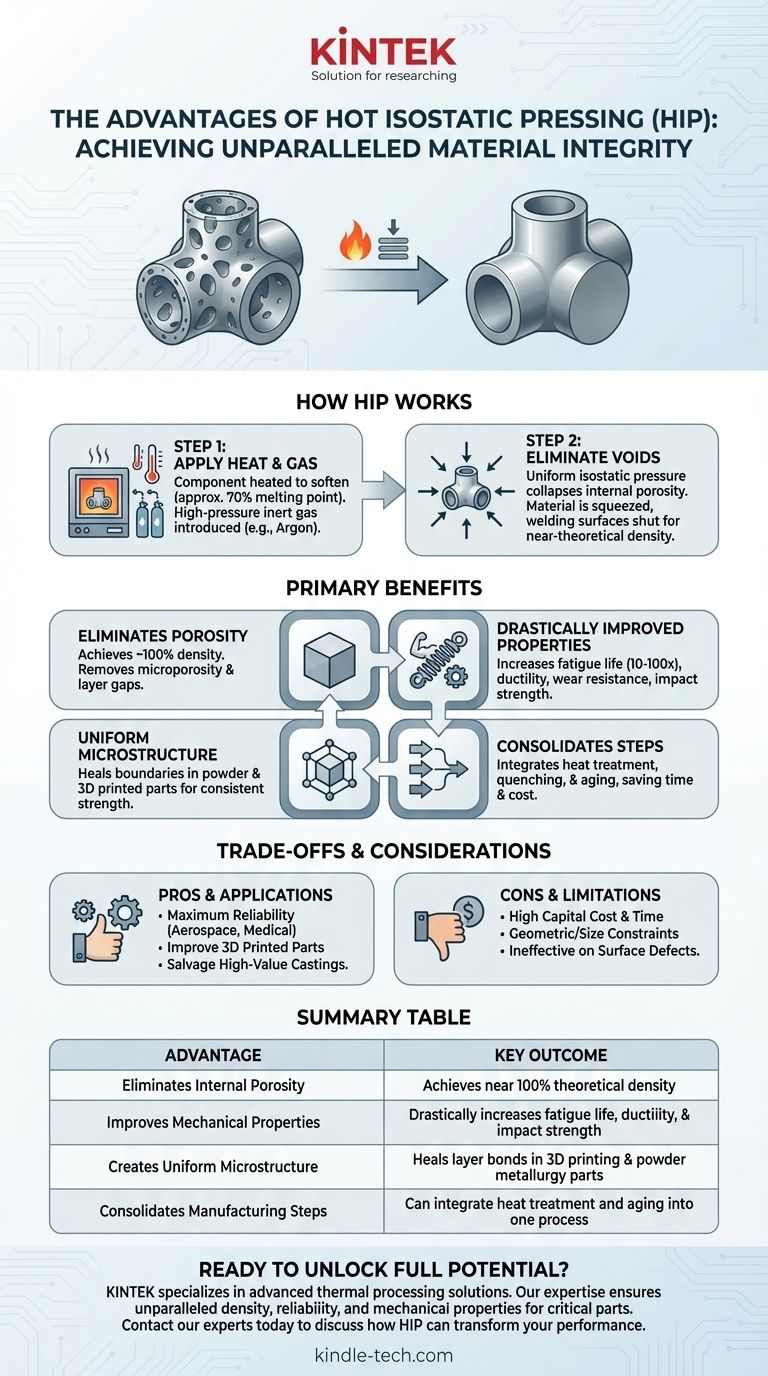

How Hot Isostatic Pressing Fundamentally Works

Hot Isostatic Pressing (HIP) subjects a component to both elevated temperature and high-pressure gas from all directions simultaneously. This combination is the key to its effectiveness.

The Role of Heat and Pressure

First, the component is heated in the HIP vessel to a temperature high enough to soften the material, making it malleable on a microscopic level. This temperature is typically around 70% of the material's melting point.

Once the material is pliable, extremely high-pressure inert gas (like argon) is introduced, exerting uniform pressure on every surface of the part. This isostatic pressure effectively collapses any internal voids, pores, or microscopic gaps within the material.

Achieving Near-Theoretical Density

Because the pressure is applied equally from all directions, it squeezes the material together and welds the internal surfaces of these voids shut. The result is a fully dense component with its internal defects eliminated, bringing its density close to the theoretical maximum for that alloy.

The Primary Benefits of HIP Treatment

The physical elimination of internal defects is the root cause of the significant performance improvements seen in HIP-treated parts.

Eliminating Internal Porosity

HIP is unmatched in its ability to remove internal microporosity in castings and the microscopic voids that can form between layers in additively manufactured (3D printed) parts. This creates a solid, homogenous material.

Drastically Improved Mechanical Properties

With internal defects removed, there are fewer initiation points for cracks to form and grow. This leads to a dramatic increase in fatigue life, which can be improved by a factor of 10 to 100 times. It also enhances ductility, impact strength, and wear resistance.

Creating a Uniform Microstructure

For powder metallurgy and 3D printed parts, HIP helps to heal the boundaries between individual powder particles or printed layers. This process creates a consistent and uniform microstructure, ensuring that the part's strength is the same in all directions.

Consolidating Manufacturing Steps

Modern HIP processes can integrate heat treatment, quenching, and aging cycles into a single session. This consolidation can reduce the total number of manufacturing steps, saving significant production time and cost for complex components.

Understanding the Trade-offs and Considerations

While powerful, HIP is not a universal solution. Understanding its limitations is critical for making an informed decision.

Cost and Complexity

HIP equipment represents a significant capital investment, and the process itself adds cost and time to the manufacturing cycle. It is typically reserved for high-value components where performance and reliability are non-negotiable.

Geometric and Sizing Constraints

Parts must physically fit inside the HIP unit's heated pressure vessel. This places a practical limit on the size of the components that can be treated.

Not a Cure for Surface Defects

HIP is only effective on internal, hermetically sealed voids. It cannot close surface-breaking cracks or pores because the pressurized gas will enter the crack, equalizing the pressure and preventing it from closing. Parts with surface defects require other repair methods.

When to Choose Hot Isostatic Pressing

Applying HIP should be a strategic decision based on your component's requirements and failure modes.

- If your primary focus is maximum reliability and fatigue life: Use HIP for critical components in aerospace, medical implants, or power generation where failure could be catastrophic.

- If your primary focus is improving additively manufactured parts: Use HIP as a standard post-processing step to achieve mechanical properties comparable to wrought or forged materials.

- If your primary focus is salvaging high-value castings: Use HIP to eliminate internal microporosity, improving mechanical performance and increasing the yield of acceptable parts.

- If your primary focus is cost-sensitive, non-critical parts: The added expense of HIP is likely not justified, and conventional heat treatments are more appropriate.

By understanding its function, you can leverage HIP not just as a repair step, but as a strategic tool to achieve unparalleled material integrity.

Summary Table:

| Advantage | Key Outcome |

|---|---|

| Eliminates Internal Porosity | Achieves near 100% theoretical density |

| Improves Mechanical Properties | Drastically increases fatigue life, ductility, and impact strength |

| Creates Uniform Microstructure | Heals layer bonds in 3D printing and powder metallurgy parts |

| Consolidates Manufacturing Steps | Can integrate heat treatment and aging into one process |

Ready to unlock the full potential of your high-performance components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing, to serve the demanding needs of laboratories and manufacturers in aerospace, medical, and additive manufacturing. Our expertise ensures your critical parts achieve unparalleled density, reliability, and mechanical properties.

Contact our experts today to discuss how HIP can transform your material performance and product reliability.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components