In short, isostatic pressing provides superior material quality and design flexibility. Its primary advantages are the ability to create parts with highly uniform density and strength in all directions, and to form complex shapes that are impossible to make with traditional uniaxial pressing methods.

Traditional powder compaction methods introduce internal weaknesses and limit design freedom. Isostatic pressing overcomes these fundamental limitations by applying pressure equally from all directions, resulting in superior material integrity and greater geometric flexibility.

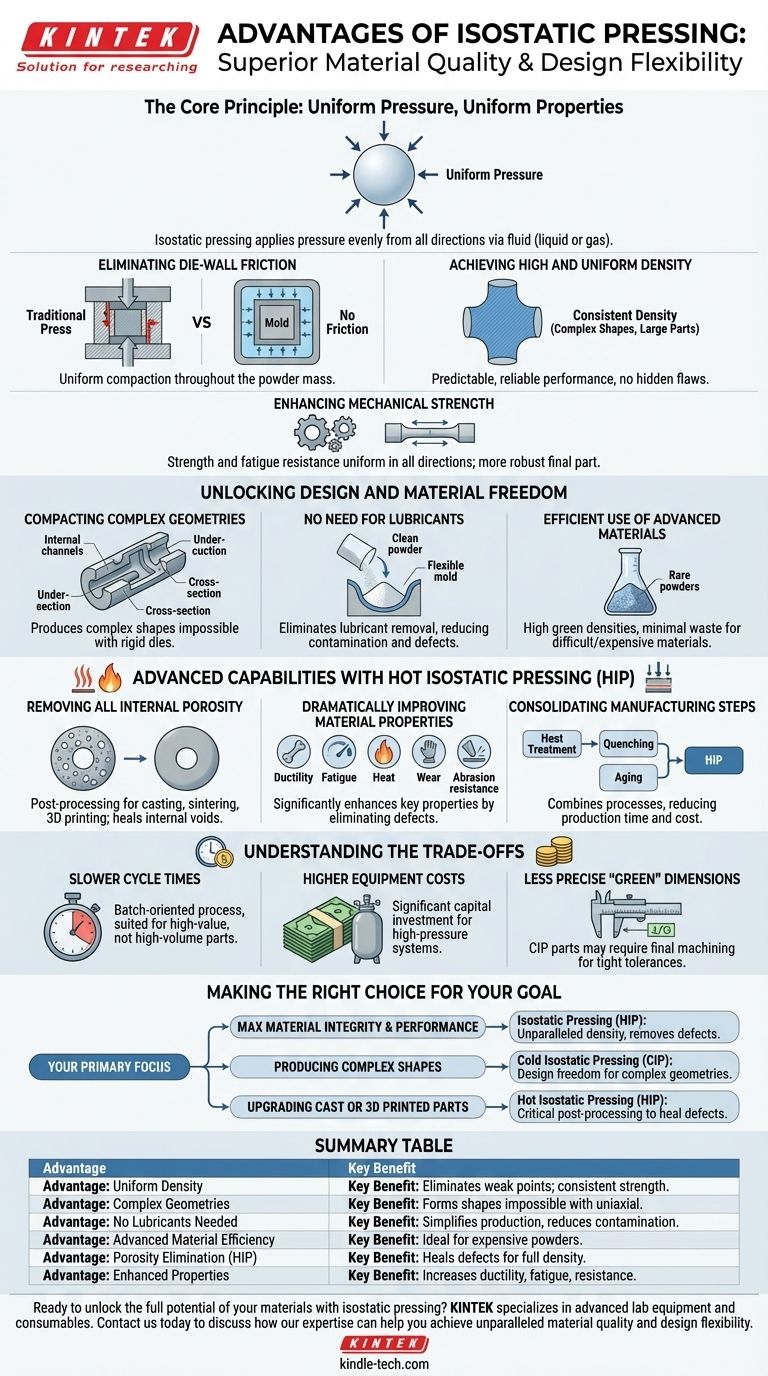

The Core Principle: Uniform Pressure, Uniform Properties

Isostatic pressing fundamentally changes how compaction forces are applied. Instead of a single-axis punch, it uses a fluid—either liquid (Cold Isostatic Pressing) or gas (Hot Isostatic Pressing)—to exert pressure evenly over the entire surface of the part.

Eliminating Die-Wall Friction

In conventional uniaxial pressing, friction between the powder and the rigid die walls prevents pressure from being transmitted evenly. This is a primary cause of density variations and weak points.

Isostatic pressing completely eliminates die-wall friction, allowing the compaction pressure to be applied uniformly throughout the powder mass.

Achieving High and Uniform Density

The direct result of uniform pressure is a part with exceptionally uniform density. This holds true even for parts with complex shapes or large height-to-diameter ratios, which are notoriously difficult for other methods.

This uniformity ensures predictable, reliable performance without hidden internal flaws.

Enhancing Mechanical Strength

Because the density is consistent throughout the component, the resulting mechanical properties, such as strength and fatigue resistance, are also uniform in all directions.

There are no inherent weak planes or internal stresses introduced during the compaction process, leading to a more robust final part.

Unlocking Design and Material Freedom

The use of a flexible mold and fluid pressure removes many of the constraints imposed by rigid metal dies, opening up new possibilities for engineers and designers.

Compacting Complex Geometries

Isostatic pressing excels at producing somewhat complex shapes that cannot be ejected from a rigid die cavity. This includes parts with undercuts, varying cross-sections, or internal cavities.

No Need for Lubricants

The process compacts powder effectively without the need for admixed lubricants. This simplifies production by eliminating the lubricant removal step (burn-off) required in other methods, which can be a source of contamination or defects.

Efficient Use of Advanced Materials

This method is highly effective for difficult-to-compact or expensive materials. It achieves high green densities with exceptional material utilization, minimizing waste of valuable powders.

Advanced Capabilities with Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) combines immense pressure with high temperature, transforming it into a powerful tool for not just forming parts, but for perfecting them.

Removing All Internal Porosity

HIP is used as a post-processing step to completely remove porosity in components made by casting, sintering, or additive manufacturing (3D printing).

It effectively heals internal voids and remedies issues like poor layer adhesion in 3D printed parts, creating a fully dense, uniform microstructure.

Dramatically Improving Material Properties

By eliminating internal defects, HIP significantly enhances key material properties. The process is proven to increase a part's ductility, fatigue resistance, and resistance to heat, wear, and abrasion.

Consolidating Manufacturing Steps

For certain materials, the HIP cycle can be engineered to combine heat treatment, quenching, and aging processes into a single, efficient operation. This consolidation can dramatically reduce overall production time and cost.

Understanding the Trade-offs

While powerful, isostatic pressing is not a universal solution. Understanding its limitations is key to making an informed decision.

Slower Cycle Times

Compared to high-speed automated uniaxial presses that can produce thousands of parts per hour, isostatic pressing is a slower, batch-oriented process. It is better suited for high-value components than for high-volume, low-cost parts.

Higher Equipment Costs

The high-pressure vessels and complex control systems required for isostatic pressing represent a significant capital investment compared to conventional mechanical or hydraulic presses.

Less Precise "Green" Dimensions

Parts formed via Cold Isostatic Pressing (CIP) often have less precise dimensional tolerances in their pre-sintered ("green") state compared to die-compacted parts. They typically require a final machining step to meet tight specifications.

Making the Right Choice for Your Goal

Selecting the correct process depends entirely on your project's specific requirements for performance, complexity, and volume.

- If your primary focus is maximum material integrity and performance: Isostatic pressing, particularly HIP, provides unparalleled density and removes the internal defects that limit other methods.

- If your primary focus is producing complex shapes from powder: Cold Isostatic Pressing (CIP) offers the design freedom to create geometries that are impossible to achieve with traditional uniaxial presses.

- If your primary focus is upgrading cast or 3D printed components: Hot Isostatic Pressing (HIP) is a critical post-processing step to heal defects and unlock the full potential of the material's properties.

By understanding these advantages, you can select the right pressing technology to meet the most demanding material and design specifications.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Uniform Density | Eliminates weak points; consistent strength in all directions. |

| Complex Geometries | Forms shapes impossible with uniaxial pressing (undercuts, cavities). |

| No Lubricants Needed | Simplifies production and reduces contamination risk. |

| Advanced Material Efficiency | Ideal for difficult-to-compact or expensive powders. |

| Porosity Elimination (HIP) | Heals internal defects in cast or 3D-printed parts for full density. |

| Enhanced Properties | Increases ductility, fatigue resistance, and wear/heat resistance. |

Ready to unlock the full potential of your materials with isostatic pressing?

KINTEK specializes in advanced lab equipment and consumables, providing the precise tools needed for superior material processing. Whether you're developing complex components or seeking to enhance the integrity of high-performance parts, our solutions are designed to meet your laboratory's specific needs.

Contact us today to discuss how our expertise can help you achieve unparalleled material quality and design flexibility.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- How much does an isostatic press cost? A Guide to Lab vs. Industrial Pricing

- What are the disadvantages of powder metallurgy? Key Limitations in Strength and Size

- What is the difference between sintering and pressing? A Guide to Powder Metallurgy Processes

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What is the process of isostatic graphite? A Guide to High-Performance, Uniform Material Creation