At its core, powder metallurgy (PM) offers a powerful combination of economic efficiency and material engineering that is often unmatched by other manufacturing processes. It excels at producing large quantities of complex, net-shape parts with high precision and minimal waste, giving you direct control over the component's final physical properties.

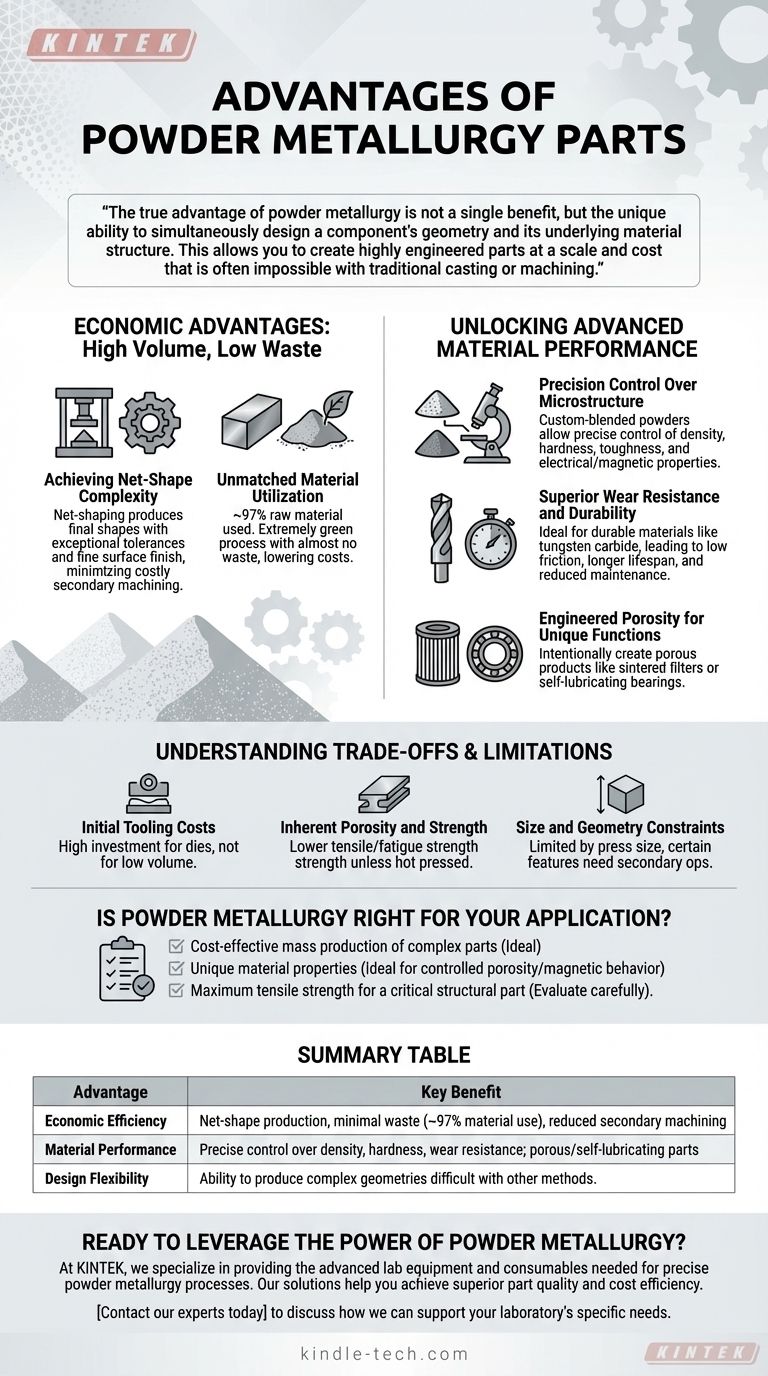

The true advantage of powder metallurgy is not a single benefit, but the unique ability to simultaneously design a component's geometry and its underlying material structure. This allows you to create highly engineered parts at a scale and cost that is often impossible with traditional casting or machining.

The Economic Advantages: High Volume, Low Waste

Powder metallurgy's primary appeal in many industries is its ability to produce parts with significant cost savings, especially at scale. These savings stem from its efficiency and process design.

Achieving Net-Shape Complexity

The PM process presses metal powder into a die that forms the component's final shape. This is known as net-shaping.

Because parts emerge from the process with exceptional tolerances and a fine surface finish, the need for costly and time-consuming secondary machining is drastically reduced or eliminated entirely. This is a massive advantage for complex parts that would otherwise require extensive milling or turning.

Unmatched Material Utilization

Powder metallurgy is an exceptionally "green" and lean manufacturing process.

Approximately 97% of the raw material used becomes part of the final product. Unlike subtractive methods like CNC machining where a significant portion of a metal block becomes scrap, PM generates almost no waste, directly lowering raw material costs.

Unlocking Advanced Material Performance

Beyond cost, powder metallurgy provides a unique platform for engineering specific material characteristics that are difficult or impossible to achieve with other methods.

Precision Control Over Microstructure

The process begins with powders that can be custom-blended. This allows for precise control over the final part's properties, such as density, hardness, toughness, and even electrical or magnetic characteristics.

By controlling the blend, compaction pressure, and sintering atmosphere, you can create a homogenous and uniform material structure optimized for a specific performance goal.

Superior Wear Resistance and Durability

PM is ideal for creating parts from materials known for extreme durability and high-temperature service, like tungsten carbide.

These materials result in components with exceptional wear resistance and a low friction coefficient. This leads to a longer operational lifespan and reduced maintenance needs for parts used in demanding applications like automotive engines and industrial tools.

Engineered Porosity for Unique Functions

A unique capability of powder metallurgy is the ability to intentionally create porous products.

This controlled porosity allows for the production of components like sintered filters, which permit gas or liquid to pass through. It also enables the creation of self-lubricating bearings, where the pores are impregnated with oil that is released during operation.

Understanding the Trade-offs and Limitations

While powerful, PM is not the solution for every application. Understanding its limitations is critical for making an informed decision.

Initial Tooling Costs

The hardened steel dies required to compact the metal powder are expensive to design and manufacture. This high initial investment means that powder metallurgy is generally not cost-effective for low-volume production runs. Its economic benefits are realized in high-volume manufacturing.

Inherent Porosity and Strength

Unless secondary processes like hot pressing are used, PM parts typically contain a small amount of residual porosity. This can result in lower tensile and fatigue strength compared to a fully dense part made from wrought bar stock or a forging. For highly-stressed structural applications, this trade-off must be carefully evaluated.

Size and Geometry Constraints

The process is limited by the size of the press and the practicalities of die design. Very large components are typically not feasible. Furthermore, certain geometric features like undercuts or threads perpendicular to the pressing direction cannot be formed and must be added in a secondary operation.

Is Powder Metallurgy Right for Your Application?

Choosing the right manufacturing process depends entirely on your primary goal. Use these points as your guide.

- If your primary focus is cost-effective mass production of complex parts: PM is an ideal choice, as its net-shaping capability minimizes material waste and costly post-processing.

- If your primary focus is a component with unique material properties (e.g., controlled porosity or specific magnetic behavior): PM offers a level of microstructural control that is difficult to achieve with other methods.

- If your primary focus is maximum tensile strength for a critical structural part: You must carefully evaluate if a PM part meets your specifications, or if a fully dense forged or machined component is more appropriate.

By understanding this blend of economic efficiency and material engineering, you can leverage powder metallurgy to solve complex manufacturing challenges.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Economic Efficiency | Net-shape production, minimal waste (~97% material use), reduced secondary machining |

| Material Performance | Precise control over density, hardness, and wear resistance; creation of porous or self-lubricating parts |

| Design Flexibility | Ability to produce complex geometries that are difficult with other methods |

Ready to leverage the power of powder metallurgy for your components?

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed for precise powder metallurgy processes. Whether you are developing new materials or scaling up production, our solutions help you achieve superior part quality and cost efficiency.

Contact our experts today to discuss how we can support your laboratory's specific powder metallurgy needs and help you unlock the full potential of this innovative manufacturing method.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press for Solid State Battery Research

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How long does sintering take? Unlock the Secrets to Optimizing Your Production Cycle

- What is the composition of pyrolysis liquids? A Deep Dive into Bio-Oil's Chemical Makeup

- What is a sputter coater? A Guide to High-Precision Thin Film Deposition

- What core process function does a Laboratory Oven perform during the coating modification of glass fiber membranes?

- What machine is used for cutting diamond? Discover the Laser Technology That Shapes Gems

- Why is pyrolysis important in waste management? Turn Waste into Fuel, Soil, and New Materials

- How long does it take to heat treat steel? From Hours to Days, Depending on Your Goal

- What role does the right ULT freezer play in a lab's success? Securing Your Most Valuable Samples