At its core, the primary advantage of a power press machine is its unparalleled ability to deliver high-speed, repeatable, and cost-effective metal forming. This is achieved through a mechanical system that converts rotational energy from a motor and flywheel into immense linear force, making it the foundation of modern mass production for stamped, punched, and formed components.

While many machines can shape metal, the power press stands out for its efficiency at scale. Its core advantage lies not just in the force it applies, but in the speed and consistency with which it can apply that force, cycle after cycle.

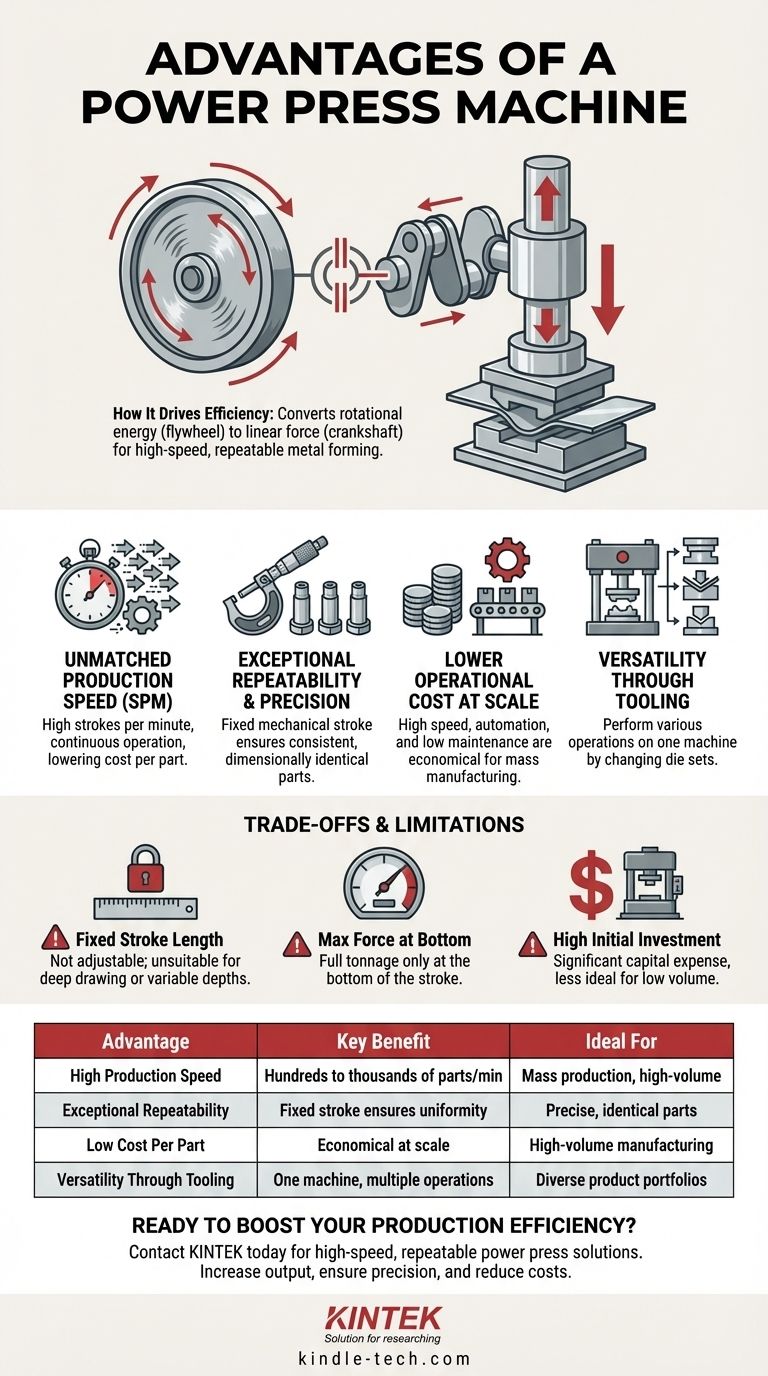

How a Power Press Drives Production Efficiency

Understanding the mechanics of a power press reveals why it is so effective. The design is elegantly simple and built for a single purpose: converting continuous rotation into powerful, discrete strokes.

The Flywheel: An Energy Reservoir

A power press uses a heavy flywheel that is kept in constant rotation by an electric motor. This flywheel acts like a mechanical battery, storing a massive amount of kinetic energy.

The Clutch and Crankshaft: Translating Energy into Force

When the operator activates the press, a clutch engages the flywheel, transferring its energy to a crankshaft. This mechanism, similar to the one in an engine, converts the rotational motion into the powerful up-and-down linear motion of the press ram.

The Die Set: Defining the Operation

The press itself provides the force, but the tooling—known as a die set—determines the outcome. This allows the same machine to perform a variety of operations like blanking, piercing, bending, or coining simply by changing the dies.

Key Advantages in Detail

The mechanical nature of a power press gives it several distinct advantages in a manufacturing environment, especially when high volume is a key requirement.

Unmatched Production Speed

Power presses are designed for speed, often measured in strokes per minute (SPM). High-speed models can run continuously, producing hundreds or even thousands of parts per minute when paired with automated coil feeders. This directly lowers the cost per part.

Exceptional Repeatability and Precision

Because the stroke length is determined by the fixed mechanics of the crankshaft, it is incredibly consistent. The ram descends to the exact same point with every cycle, ensuring every part is dimensionally identical. This level of repeatability is crucial for quality control and minimizes scrap.

Lower Operational Cost at Scale

While the initial investment is significant, the cost per piece is extremely low in high-volume production. The high speed, potential for automation, and low-maintenance mechanical design make them highly economical for mass manufacturing.

Versatility Through Tooling

A single power press can be a highly versatile asset. By investing in different die sets, a manufacturer can produce a wide portfolio of parts, from simple washers to complex automotive brackets, all on the same machine.

Understanding the Trade-offs and Limitations

No technology is perfect, and the advantages of a power press come with specific limitations. Acknowledging these is critical for making an informed decision.

Fixed Stroke Length

The biggest limitation is the fixed stroke. Unlike a hydraulic press where the stroke can be easily adjusted, a mechanical press has a set travel distance. This makes it less suitable for deep-drawing operations or jobs that require variable pressing depths.

Lack of Full Tonnage Through Stroke

A mechanical press only delivers its maximum rated tonnage at the very bottom of its stroke. The force is not consistent throughout the pressing action, which can be a limitation for certain forming or "coining" operations.

High Initial Investment

Power presses and the associated high-quality tooling represent a major capital expense. This makes them less practical for prototyping, custom fabrication, or low-volume production runs where the cost cannot be amortized over many thousands of parts.

Significant Safety Requirements

The immense force and high speed make power presses inherently dangerous if operated improperly. Modern presses require extensive safety systems, including light curtains, physical guarding, and two-hand controls, to protect operators.

Is a Power Press Right for Your Application?

Choosing the correct press technology depends entirely on your production goals. Use these points as a guide.

- If your primary focus is high-volume production of consistent parts: A power press is the industry standard and the most cost-effective solution due to its speed and automation capabilities.

- If your primary focus is absolute precision and part-to-part uniformity: The fixed mechanical action of a power press delivers unmatched repeatability, ensuring every part meets specification.

- If your primary focus is deep drawing or forming parts that require sustained pressure: You should evaluate a hydraulic press, which offers superior control over stroke length and pressure throughout the cycle.

- If you are working with prototypes or low-volume runs: The high tooling and setup costs of a power press make alternative methods, like a press brake or turret punch, far more economical.

Understanding these core principles ensures you select the right technology not just for the part you're making today, but for the long-term efficiency of your entire production line.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| High Production Speed | Hundreds to thousands of parts per minute | Mass production, high-volume runs |

| Exceptional Repeatability | Fixed mechanical stroke ensures part uniformity | Applications requiring precise, identical parts |

| Low Cost Per Part | Economical at scale due to speed and automation | High-volume manufacturing to reduce unit cost |

| Versatility Through Tooling | One machine can perform multiple operations with different dies | Diverse product portfolios using the same press |

Ready to Boost Your Production Efficiency?

If your operation demands high-volume, repeatable metal stamping, a power press from KINTEK is the solution. We specialize in providing robust lab and industrial equipment, including power presses, designed to meet the rigorous demands of modern manufacturing.

Partner with KINTEK to:

- Increase output with high-speed, automated pressing solutions.

- Ensure precision with machines built for unmatched repeatability.

- Reduce costs through efficient, scalable production systems.

Let our experts help you select the perfect power press for your needs. Contact us today to discuss your project and discover how KINTEK can enhance your production line!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation