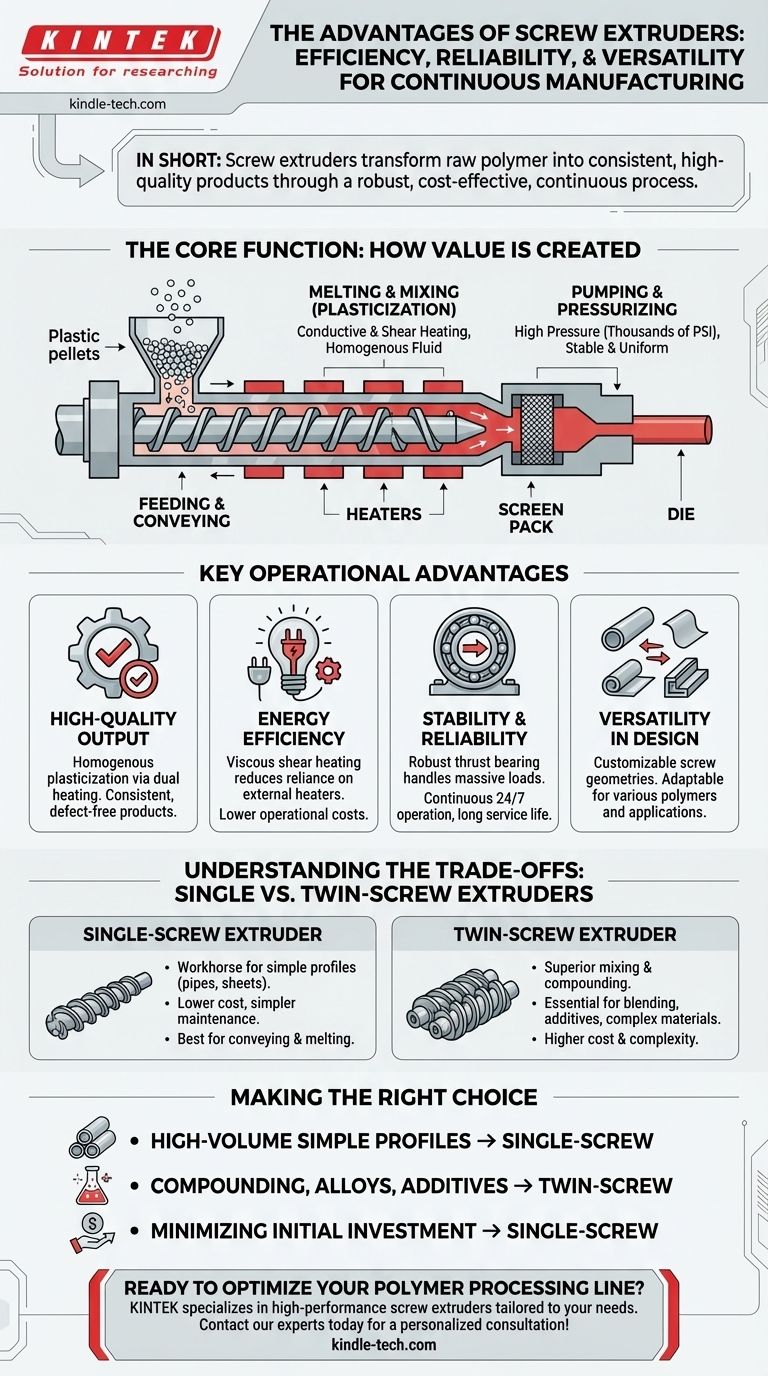

In short, screw extruders offer a powerful combination of efficiency, reliability, and versatility for continuous manufacturing. They excel at transforming raw polymer into a consistent, high-quality product through a mechanically robust and well-understood process, resulting in stable operation, long service life, and excellent cost-effectiveness for a wide range of applications.

The true advantage of a screw extruder isn't just a list of features, but its function as a reliable engine for continuous production. It provides the controlled melting, mixing, and pressure needed to consistently create high-quality products at scale.

The Core Function: How a Screw Extruder Creates Value

To understand the advantages, you must first understand the process. A screw extruder is a machine that uses a rotating screw inside a heated barrel to melt and convey thermoplastic material, forcing it through a die to create a continuous profile.

Feeding and Conveying

The process begins in the feed zone. Raw material, typically in the form of plastic pellets or powder, is gravity-fed from a hopper into the barrel at the rear of the screw. The rotation of the screw captures this material in its flights and pushes it forward.

Melting and Mixing (Plasticization)

As the material moves along the screw, it enters the compression and melting zones. The depth of the screw channel decreases, compressing the material. This compression, combined with heat from external barrel heaters and immense friction (shear heating), melts the plastic. This dual heating mechanism ensures the polymer becomes a homogenous, consistent fluid, a state known as plasticization.

Pumping and Pressurizing

In the final metering zone, the screw acts as a pump. It generates the high pressure—often thousands of PSI—required to push the molten plastic through the screen pack (for filtration) and the die. This stable pressure is critical for ensuring the final product has a consistent shape and uniform dimensions.

Key Operational Advantages Explained

Each stage of the extrusion process contributes to a set of distinct operational benefits. These are not just marketing points; they are direct results of the machine's fundamental design.

High-Quality Output and Good Plasticization

The combination of conductive heat from the barrel and shear heat from the screw's mechanical action creates a thoroughly mixed and uniform melt. This homogenous plasticization is the primary reason screw extruders produce high-quality, consistent products free from internal stresses or defects.

Energy Efficiency

While barrel heaters are needed for startup, a significant portion of the heat required to melt the plastic is generated by the mechanical shearing action of the screw itself. This phenomenon, known as viscous shear heating, means that once the process reaches a steady state, the reliance on external electrical heaters decreases, making the operation highly energy-efficient.

Stability and Reliability

Screw extruders are built for continuous, 24/7 operation. The axial pressure created by the screw is absorbed by a robust thrust bearing assembly, a critical component designed for massive loads. This heavy-duty construction is why extruders are known for their stable operation and exceptionally long service life with proper maintenance.

Versatility in Design

The "advanced design" of a screw extruder lies in its adaptability. Screw geometries can be custom-engineered for specific polymers and applications. Variables like the compression ratio, flight depth, and mixing elements can be modified to optimize performance, making the screw extruder a versatile tool for processing everything from pipes and tubing to films and custom profiles.

Understanding the Trade-offs: Single vs. Twin-Screw Extruders

The term "screw extruder" most often refers to a single-screw design, but it's crucial to understand its counterpart, the twin-screw extruder, to make an informed decision.

When a Single-Screw Excels

The single-screw extruder is the workhorse of the industry. Its simpler design makes it less expensive to purchase and maintain. It is the ideal choice for straightforward extrusion of profiles, sheets, pipes, and tubing from a single, well-behaving polymer. Its primary function is conveying and melting, not intensive mixing.

When a Twin-Screw is Necessary

A twin-screw extruder features two intermeshing screws. This design provides far superior mixing and compounding capabilities. It is essential for applications requiring the blending of polymers, the incorporation of additives like colorants and fillers, or for processing heat-sensitive or difficult-to-feed materials. This enhanced capability comes at a higher initial cost and increased operational complexity.

Making the Right Choice for Your Process

Selecting the right extruder depends entirely on your production goals and the materials you intend to process.

- If your primary focus is high-volume production of simple profiles (pipes, sheets, films) from a single polymer: A single-screw extruder offers the best combination of reliability, output, and cost-effectiveness.

- If your primary focus is compounding, creating polymer alloys, or mixing in additives and fillers: A twin-screw extruder is the necessary choice for its superior distributive and dispersive mixing capabilities.

- If your primary focus is minimizing initial capital investment for a basic extrusion task: The simpler design and lower cost of a single-screw extruder make it the clear starting point.

Ultimately, the screw extruder is the foundational machine of the plastics industry, providing a reliable and efficient method for converting raw polymer into valuable, finished goods.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| High-Quality Output | Homogenous plasticization via shear & conductive heating | Consistent, defect-free products with uniform dimensions |

| Energy Efficiency | Viscous shear heating reduces reliance on external heaters | Lower operational costs and sustainable processing |

| Stability & Reliability | Robust thrust bearing assembly for continuous operation | Long service life and minimal downtime for high-volume production |

| Versatility | Customizable screw geometry for different polymers/applications | Adaptable to various tasks from pipes to films and custom profiles |

Ready to optimize your polymer processing line?

At KINTEK, we specialize in providing high-performance lab equipment and consumables, including reliable screw extruders tailored to your specific needs. Whether you're involved in R&D, compounding, or high-volume production, our expertise ensures you get the right solution for efficient, continuous operation.

Let's discuss how a KINTEK screw extruder can enhance your productivity and product quality. Contact our experts today for a personalized consultation!

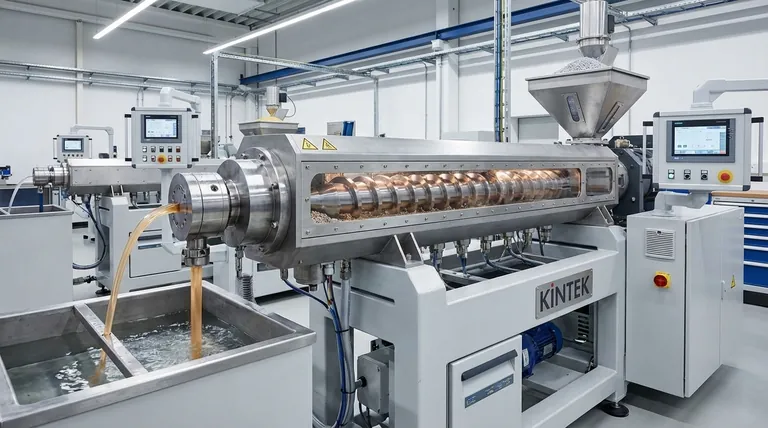

Visual Guide

Related Products

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What tool can break diamond? Understanding the Science and Techniques

- What precautions should be taken when using hydraulic forming or cutting equipment to prepare stainless steel corrosion specimens? Ensure Accuracy.

- What are the advantages of diamond cutting tool material? Achieve Superior Precision and Productivity

- What is a diamond machine? Unlock the Power of Diamond Tooling for Your Toughest Materials

- Are diamonds used in machines? Unlock Superior Performance with Diamond Tools