At its core, the sintering process transforms powdered materials into a solid, coherent mass using heat and pressure without melting the material to the point of liquefaction. This fundamental mechanism grants it a unique combination of advantages, ranging from superior material properties and the ability to create complex shapes to remarkable cost-effectiveness in high-volume production. It allows for the creation of nearly net-shaped parts with high repeatability, excellent surface finishes, and enhanced strength.

Sintering should be understood not just as a manufacturing method, but as a material engineering tool. It uniquely allows for the creation of parts with precisely controlled microstructures and properties, unlocking designs and performance characteristics that are often unattainable with traditional casting or machining.

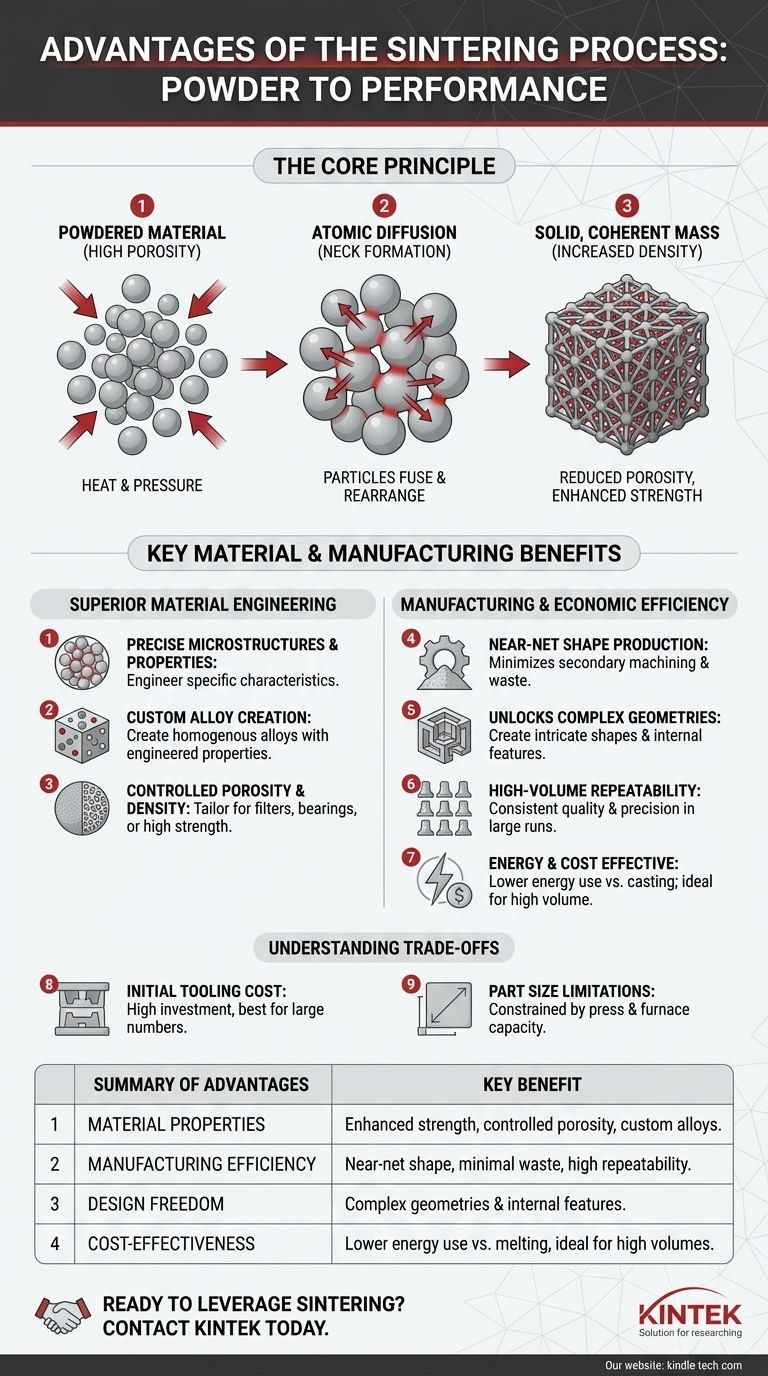

The Core Principle: Transforming Powder into Strength

Sintering is a process of atomic diffusion. By heating a compacted powder to a temperature below its melting point, atoms at the contact points of the particles diffuse across the boundaries, fusing the particles together and creating a solid piece.

Reducing Porosity and Increasing Density

The initial component is a compressed powder with significant empty space, or porosity, between particles. During sintering, particles fuse and rearrange, dramatically reducing this empty space.

This reduction in porosity leads to a denser final part, which is a primary factor in its increased strength and improved thermal and electrical conductivity.

Fusing Particles to Enhance Strength

As atoms migrate between particles, they form "necks" at the contact points. These necks grow over time, effectively welding the individual particles into a single, interconnected lattice.

This process is what gives a sintered part its mechanical integrity and strength, transforming a fragile "green" compact into a robust, durable component.

Alloying at the Atomic Level

Sintering is also an effective way to create alloys. Different elemental powders, such as iron, copper, nickel, and graphite, can be mixed before compaction.

During heating, these elements diffuse into one another, creating a homogenous alloy with specific, engineered properties throughout the final part.

Manufacturing and Economic Advantages

Beyond altering material properties, sintering offers significant production benefits that directly impact cost and design freedom.

Achieving Near-Net Shape and Reducing Waste

Sintering produces parts that are very close to their final dimensions, a state known as near-net shape.

This drastically minimizes or even eliminates the need for secondary machining operations, which saves time, reduces material waste, and lowers overall cost. This makes the process highly efficient and environmentally friendly.

Unlocking Complex Geometries

Molding powder allows for the creation of intricate shapes, internal voids, and complex features that would be difficult, expensive, or impossible to produce with subtractive methods like machining.

This advantage is critical for mass-producing complex components like gears, cams, and structural automotive parts.

High-Volume Repeatability and Precision

The use of durable, reusable molds and highly controlled process parameters ensures that every part produced is virtually identical.

Sintering delivers excellent dimensional accuracy and high repeatability over production runs of thousands or even millions of units, ensuring consistent quality and performance.

Energy and Cost Efficiency

Because sintering operates below the material's melting point, it consumes significantly less energy than casting processes.

This energy saving, combined with reduced material waste and minimal post-processing, makes sintering an exceptionally cost-effective method for medium- to high-volume manufacturing.

Understanding the Trade-offs

While powerful, sintering is not the optimal choice for every application. Understanding its limitations is key to using it effectively.

The Initial Tooling Cost

Creating the high-precision dies and molds required for powder compaction involves a significant upfront investment.

This initial cost means sintering is generally not economical for very low-volume production or one-off prototypes. The benefits are realized when tooling costs are amortized over a large number of parts.

Limitations on Part Size

The size of a sintered part is constrained by the capacity of the compaction press and the size of the furnace. Extremely large components are often not feasible with standard sintering equipment.

Residual Porosity Concerns

While sintering significantly reduces porosity, achieving 100% density is difficult and often requires secondary processes. For some extreme, high-stress applications, the minimal residual porosity might be a performance-limiting factor compared to a fully dense wrought or forged material.

How to Apply This to Your Project

Your choice of manufacturing process must align directly with your project's primary goal.

- If your primary focus is cost-effective mass production of complex parts: Sintering is an ideal choice, as its ability to create near-net shapes with high repeatability minimizes waste and post-processing costs over large volumes.

- If your primary focus is extreme material requirements: Choose sintering for components made from materials with very high melting points, like tungsten or molybdenum, which are impractical to process via melting.

- If your primary focus is unique material properties: Use sintering when you need to engineer a specific characteristic, such as the controlled porosity required for a filter or the specific alloy composition for a high-performance bearing.

Ultimately, adopting sintering allows you to engineer both the material and the manufacturing process simultaneously for an optimal outcome.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Properties | Enhanced strength, controlled porosity, and custom alloy creation. |

| Manufacturing Efficiency | Near-net shape production, minimal waste, and high repeatability. |

| Design Freedom | Ability to create complex geometries and internal features. |

| Cost-Effectiveness | Lower energy use vs. melting processes, ideal for high volumes. |

Ready to leverage sintering for your lab's production needs? KINTEK specializes in providing the precise lab equipment and consumables required for advanced sintering processes. Our solutions help you achieve superior material properties and manufacturing efficiency. Contact us today to discuss how we can support your project with reliable, high-performance sintering tools!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does a vacuum hot pressing sintering furnace facilitate TiBw/TA15 synthesis? Achieve 100% Dense Titanium Composites

- How does a vacuum hot press sintering furnace facilitate a high-quality bond? Achieve Superior Metallurgical Coating

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the advantages of using a vacuum hot pressing sintering furnace? Superior Density for Nanocrystalline Fe3Al