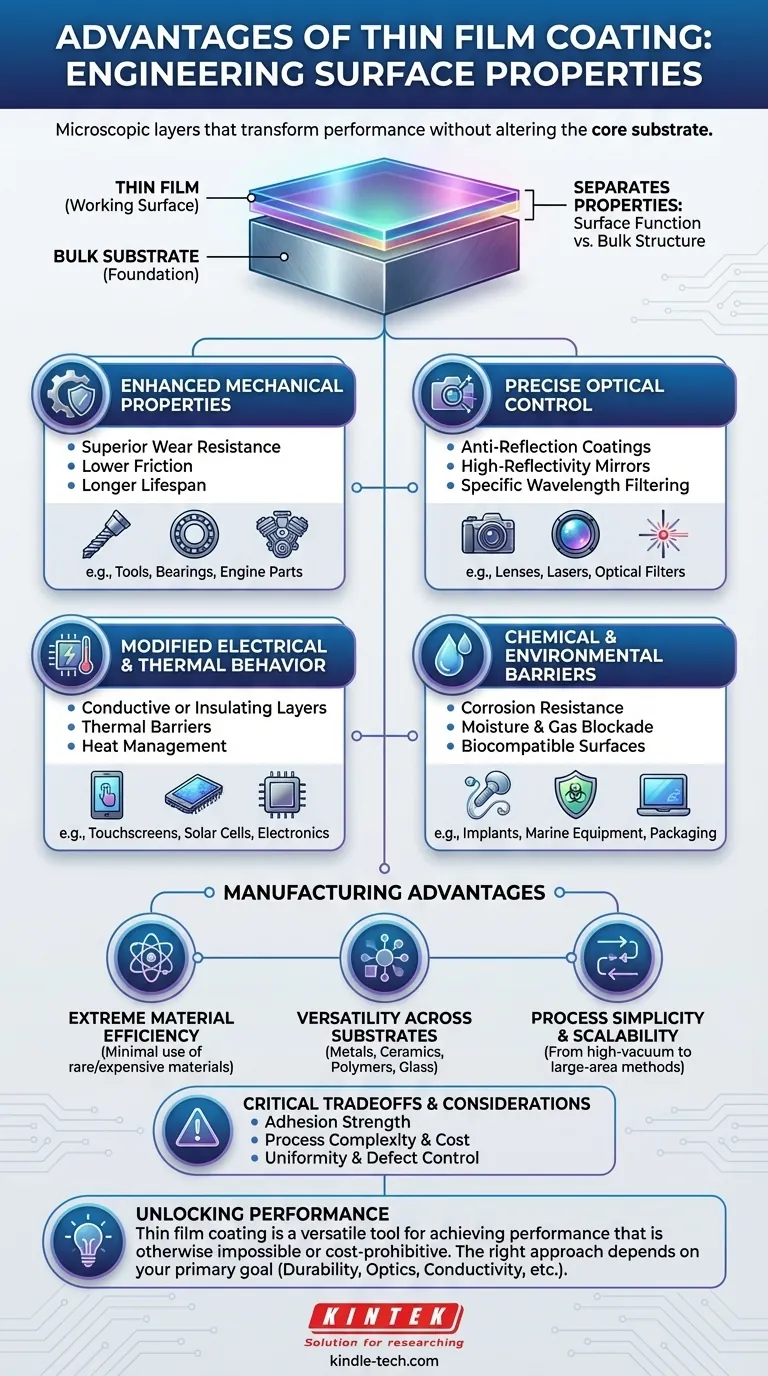

At its core, thin film coating is a technology used to apply a microscopic layer of material onto a surface, fundamentally altering its properties without changing the underlying substrate. The primary advantages are the ability to add new functions—like wear resistance, optical filtering, or electrical conductivity—to a bulk material with extreme precision and minimal use of resources.

Thin film coatings are not just protective layers; they are a strategic method for engineering surface properties. They enable performance and functionality that the base material alone cannot achieve, often with significant gains in efficiency and durability.

How Thin Films Transform a Surface

To understand the advantages, it's crucial to first understand the principle. A thin film acts as the new "working surface" of an object, while the bulk material provides the structural foundation.

Defining "Thin" Film

A thin film is a layer of material ranging from fractions of a nanometer to several micrometers in thickness. At this scale, the properties of the film can be dramatically different from the same material in bulk form.

The Principle of Surface Engineering

This technology separates the desired surface properties (e.g., hardness, reflectivity) from the required bulk properties (e.g., strength, weight, cost). You can use a cheap, lightweight plastic for a device's body but apply a thin film to give its lens a scratch-resistant, anti-reflective surface.

Key Performance Advantages

The true power of thin films lies in the wide range of functional properties they can introduce to a substrate.

Enhanced Mechanical Properties

By depositing very hard materials like titanium nitride (TiN) or diamond-like carbon (DLC), you can drastically improve a component's surface. This leads to superior wear resistance, lower friction, and a longer operational lifespan for tools, bearings, and engine parts.

Precise Control of Light

Thin films are essential in optics. By stacking multiple layers of specific materials and thicknesses, engineers can create highly specialized coatings. These include anti-reflection coatings for camera lenses, high-reflectivity mirrors for lasers, and band-pass filters that only allow specific wavelengths of light to pass through.

Modified Electrical and Thermal Behavior

Thin films can be used to add electrical functionality. Transparent conductive oxides (like ITO) are used in touchscreens and solar cells. Conversely, insulating films like silicon dioxide are fundamental to manufacturing microchips. They can also act as thermal barriers, managing heat in high-performance electronics.

Chemical and Environmental Barriers

A dense, non-porous thin film can seal a substrate from its environment. This is critical for preventing corrosion on metals, blocking moisture permeation in electronics, and creating biocompatible surfaces for medical implants.

Understanding the Manufacturing Advantages

Beyond performance, the methods used to create thin films offer their own set of benefits.

Extreme Material Efficiency

Because the layers are incredibly thin, the amount of material required is minuscule. This makes it economically feasible to use expensive or rare materials, like gold or platinum, to achieve a desired surface effect without making the entire object out of them.

Versatility Across Substrates and Scales

Thin films can be applied to a vast range of substrates, including metals, ceramics, polymers, and glass. The processes for creating them can be adapted for different needs. For example, some methods excel at coating complex 3D shapes, while others are designed for massive, flat surfaces like architectural glass.

Process Simplicity and Low Temperatures

While some methods require high vacuum and temperature, others like the sol-gel process are known for their relative simplicity. These techniques allow for excellent film uniformity over large areas and can often be performed at low temperatures, making them suitable for coating heat-sensitive substrates like plastics.

Critical Trade-offs and Considerations

Thin film technology is powerful but not without its challenges. Objectivity requires acknowledging them.

The Challenge of Adhesion

A coating is only as effective as its bond to the substrate. Poor adhesion can cause the film to peel, flake, or delaminate, rendering it useless. Achieving a strong, durable bond is a critical and often complex aspect of the coating process.

Process Complexity and Cost

High-performance films created with processes like Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) require sophisticated, high-vacuum equipment. The initial capital investment and operational complexity for these systems can be substantial.

Uniformity and Defect Control

Microscopic defects like pinholes, cracks, or variations in thickness can compromise the entire function of the film. Maintaining strict process control to ensure uniformity and minimize defects is essential, especially in high-precision applications like optics and semiconductors.

Making the Right Choice for Your Goal

Selecting the right thin film approach depends entirely on your primary objective.

- If your primary focus is mechanical durability: Investigate hard coatings like TiN or DLC, typically applied via PVD, as they offer the best wear resistance for tools and components.

- If your primary focus is optical precision: Focus on dielectric or metallic stacks applied via methods like sputtering or evaporation, which allow for nanometer-level thickness control.

- If your primary focus is cost-effective, large-area coverage: Explore atmospheric pressure techniques like the sol-gel method or spray pyrolysis, especially if extreme performance is not the top priority.

- If your primary focus is creating a conductive, transparent layer: Your best option will likely be sputtered Transparent Conductive Oxides (TCOs) like Indium Tin Oxide (ITO).

Ultimately, thin film coating is a versatile and powerful tool for unlocking material performance that would otherwise be impossible or cost-prohibitive.

Summary Table:

| Advantage Category | Key Benefits |

|---|---|

| Mechanical Properties | Wear resistance, lower friction, longer lifespan |

| Optical Control | Anti-reflection, high reflectivity, precise filtering |

| Electrical & Thermal | Conductive or insulating layers, thermal management |

| Chemical & Environmental | Corrosion resistance, moisture barriers, biocompatibility |

| Manufacturing Efficiency | Material efficiency, versatility, process simplicity |

Ready to engineer superior surface properties for your components?

KINTEK specializes in advanced thin film coating solutions and lab equipment. Whether you need to enhance wear resistance, achieve precise optical filtering, or add electrical functionality to your substrates, our expertise can help you select the right coating process and materials for your specific application.

Contact our experts today to discuss how our thin film technologies can improve your product's performance, durability, and efficiency.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems