In applications demanding precision and stability, the advantages of thin film technology are definitive. Thin film components are chosen for their exceptionally tight tolerances, low noise, and superior stability across temperature changes. This performance, along with their suitability for high-frequency circuits, distinguishes them clearly from their thick film counterparts.

The choice between thin and thick film technology is a classic engineering trade-off. Thin film is the superior choice for applications where precision, stability, and high-frequency performance are non-negotiable, often involving a higher cost.

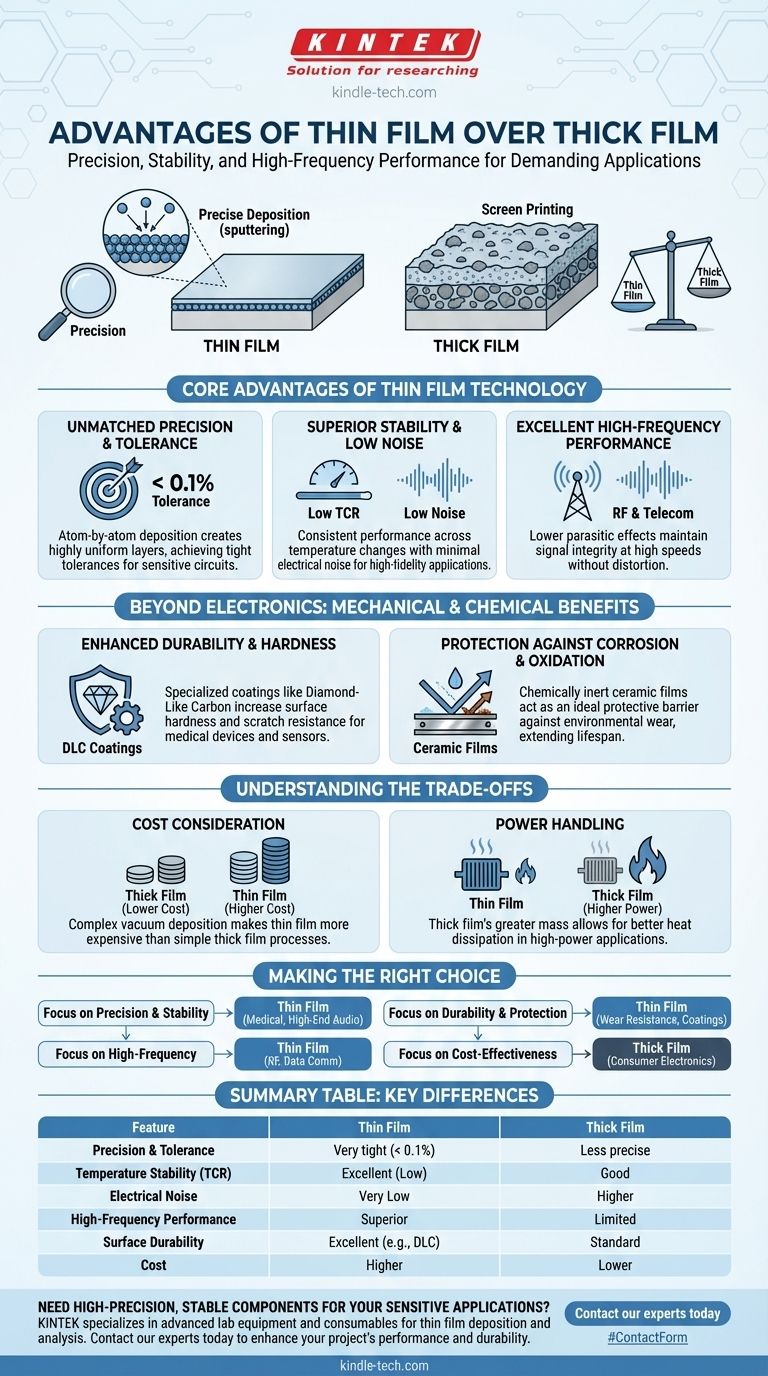

Core Advantages of Thin Film Technology

The benefits of thin film stem directly from its manufacturing process, where materials are deposited atom by atom or molecule by molecule in a vacuum. This meticulous process enables a level of control that is impossible to achieve with the screen-printing methods used for thick film.

Unmatched Precision and Tolerance

Thin film deposition techniques, like sputtering, allow for the creation of extremely uniform and precisely controlled layers.

This manufacturing control results in components, especially resistors, with very tight tolerances (often below 0.1%). This means the actual performance of the component is extremely close to its specified value, which is critical for sensitive circuits.

Superior Stability and Low Noise

A key advantage of thin film is its low Temperature Coefficient of Resistance (TCR). This means its electrical resistance changes very little as the temperature fluctuates, ensuring stable and predictable performance.

Furthermore, the uniform structure of thin film generates significantly less electrical noise than thick film. This makes it essential for high-fidelity audio, precision measurement tools, and sensitive sensor applications.

Excellent High-Frequency Performance

Thin film components are better suited for high-frequency applications, such as in radio frequency (RF) and telecommunications equipment.

Their construction results in lower parasitic capacitance and inductance, which helps maintain signal integrity at high speeds without distortion.

Beyond Electronics: Mechanical and Chemical Benefits

While often discussed in the context of resistors and circuits, thin film coatings provide significant protective advantages across many industries.

Enhanced Durability and Hardness

Specialized thin films, such as Diamond-Like Carbon (DLC), can dramatically increase the hardness and scratch resistance of a surface.

These coatings are applied to everything from medical devices and microelectronics to sensors, improving their lifespan and durability in demanding environments.

Protection Against Corrosion and Oxidation

Ceramic thin films are chemically inert and exceptionally hard, making them an ideal protective barrier.

They are widely used to shield materials from corrosion, oxidation, and wear. On cutting tools, for example, a ceramic thin film can extend the usable life by several orders of magnitude.

Understanding the Trade-offs

No technology is superior in every situation. The precision of thin film comes with specific considerations that make thick film a better choice for certain applications.

The Primary Factor: Cost

The vacuum deposition processes required for thin film are inherently more complex and expensive than the simple screen-printing and firing process used for thick film.

This cost difference is the primary reason thick film technology remains dominant in mass-market consumer electronics where a high degree of precision is not required.

Power Handling Limitations

Generally, thick film components can handle more power than their thin film equivalents. The greater mass of the resistive material in thick film allows it to dissipate more heat.

For high-power applications, thick film is often the more robust and cost-effective choice.

Making the Right Choice for Your Application

Selecting the correct technology requires a clear understanding of your project's primary goal.

- If your primary focus is precision and stability: Thin film is the correct choice for applications like medical sensors, test and measurement equipment, or high-end audio circuits.

- If your primary focus is high-frequency performance: Thin film is necessary for RF circuits and high-speed data communication to ensure signal integrity.

- If your primary focus is durability and surface protection: Specialized thin films like DLC or ceramics offer unparalleled resistance to wear, corrosion, and scratching.

- If your primary focus is cost-effectiveness for a general-purpose application: Thick film provides excellent value and is more than adequate for many consumer and automotive electronics.

Ultimately, understanding these core differences empowers you to select the right film technology based on performance requirements, not just preference.

Summary Table:

| Advantage | Thin Film | Thick Film |

|---|---|---|

| Precision & Tolerance | Very tight (< 0.1%) | Less precise |

| Temperature Stability (TCR) | Excellent (Low) | Good |

| Electrical Noise | Very Low | Higher |

| High-Frequency Performance | Superior (Lower parasitics) | Limited |

| Surface Durability | Excellent (e.g., DLC coatings) | Standard |

| Cost | Higher | Lower (Cost-effective) |

Need high-precision, stable components for your sensitive applications?

At KINTEK, we specialize in advanced lab equipment and consumables for thin film deposition and analysis. Whether you're developing medical sensors, RF circuits, or need durable protective coatings, our solutions deliver the precision and reliability your laboratory demands.

Contact our experts today to discuss how our thin film technology can enhance your project's performance and durability.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- CVD Diamond Cutting Tool Blanks for Precision Machining

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells