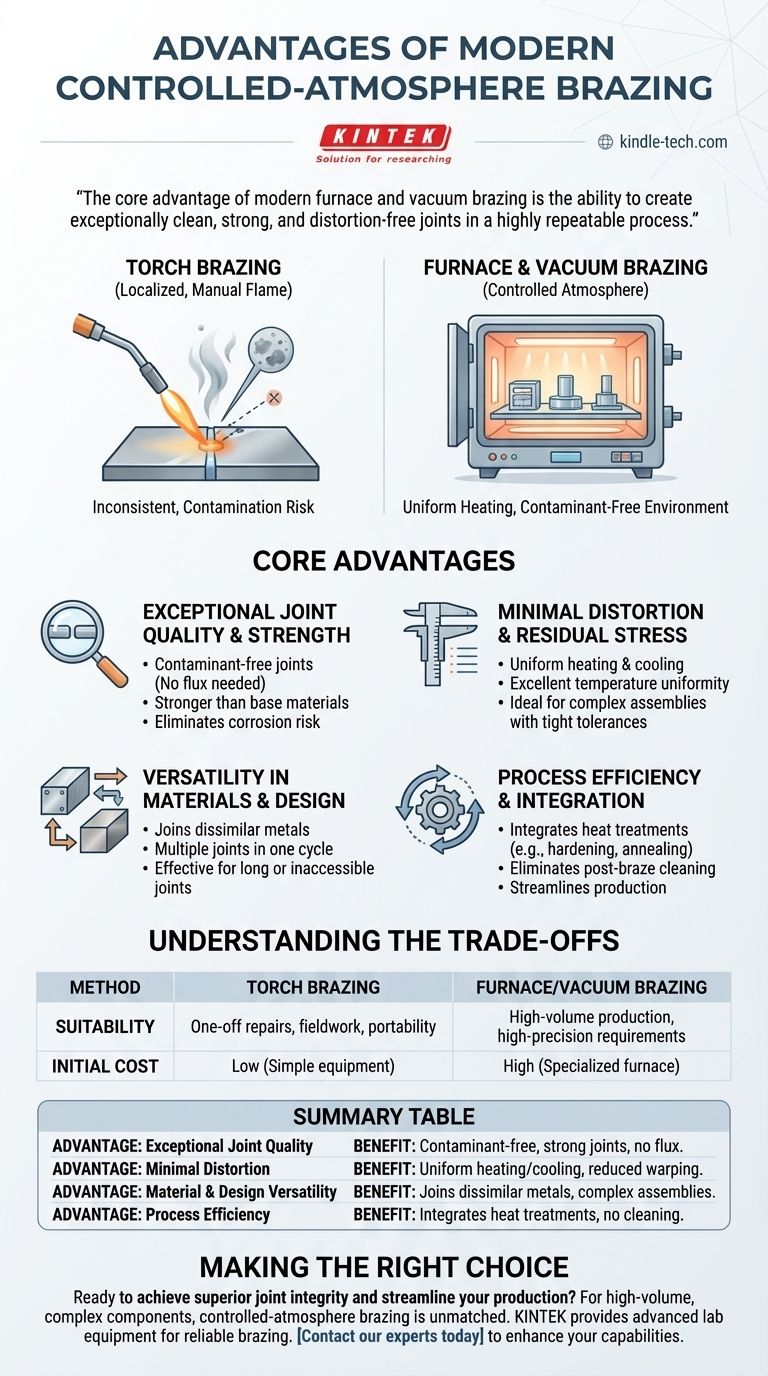

While your question is about torch brazing, the most significant advantages in modern manufacturing come from controlled-atmosphere methods like furnace and vacuum brazing. These processes offer superior control, cleanliness, and strength, making them ideal for high-precision or complex assemblies where manual torch methods would introduce inconsistencies and contamination.

The core advantage of modern furnace and vacuum brazing is the ability to create exceptionally clean, strong, and distortion-free joints in a highly repeatable process. This is achieved by precisely controlling the heating and cooling of the entire assembly within a protective atmosphere, eliminating the need for corrosive fluxes.

Understanding Furnace and Vacuum Brazing

Torch brazing involves a localized, manually applied flame. In contrast, furnace and vacuum brazing heat the entire component assembly inside a sealed chamber. This fundamental difference is the source of their primary advantages.

Exceptional Joint Quality and Strength

The controlled environment is key to quality. By removing oxygen and other contaminants, these methods produce superior joints.

This results in a contaminant-free joint, as impurities like oxides are prevented from forming or are removed by the vacuum. This process eliminates the risk of flux inclusions or corrosion that can compromise the joint over time.

The final joint is often stronger than the base materials themselves. The filler metal forms a thin, uniform film that provides high integrity and strength without fusing or damaging the parent metals.

Minimal Distortion and Residual Stress

Uniform heating and cooling are critical for maintaining the dimensional accuracy of components.

Furnace and vacuum brazing provide excellent temperature uniformity across the entire part. This slow, even heating and cooling cycle drastically reduces the internal stresses that cause warping and distortion.

This precision makes the process ideal for complex and delicate assemblies where maintaining tight tolerances is non-negotiable.

Versatility in Materials and Design

These methods are not limited to joining simple, identical metals.

They excel at joining dissimilar metals and parts with different thicknesses, which can be very difficult with other methods.

The process allows for the creation of multiple joints at once. An entire complex assembly with dozens of connection points can be brazed in a single cycle, ensuring consistency.

It's also highly effective for long or inaccessible joints, as the filler metal is drawn into the gaps uniformly by capillary action.

Process Efficiency and Integration

Beyond just joining parts, furnace brazing can be combined with other essential manufacturing steps.

The process can integrate heat treatments like hardening, annealing, or age hardening into a single furnace cycle. This saves significant time and cost by eliminating separate manufacturing steps.

Because the process is so clean, it eliminates the need for post-braze cleaning to remove flux, streamlining production.

Understanding the Trade-offs

While powerful, these methods are not universally applicable. Their primary limitations are cost and scale.

The required equipment—a specialized vacuum or atmosphere furnace—represents a significant capital investment compared to a simple brazing torch.

This makes furnace and vacuum brazing best suited for high-volume production runs or applications where the absolute highest joint integrity is required, such as in the aerospace or medical industries. They are less practical for one-off repairs or fieldwork.

Making the Right Choice for Your Goal

Selecting the right brazing method depends entirely on your project's specific requirements for precision, scale, and cost.

- If your primary focus is high-volume production of complex, high-precision parts: Furnace or vacuum brazing is the superior choice for its repeatability, strength, and integrated heat-treating capabilities.

- If your primary focus is portability, low initial cost, or simple one-off repairs: A manual method like torch brazing is more practical and cost-effective, despite requiring more operator skill and offering less process control.

Ultimately, understanding the distinct advantages of controlled-atmosphere brazing empowers you to choose the process that delivers the necessary quality and efficiency for your application.

Summary Table:

| Advantage | Benefit |

|---|---|

| Exceptional Joint Quality | Contaminant-free, strong joints without flux or corrosion risk. |

| Minimal Distortion | Uniform heating/cooling reduces warping for tight tolerances. |

| Material & Design Versatility | Joins dissimilar metals and complex assemblies in one cycle. |

| Process Efficiency | Integrates heat treatments and eliminates post-braze cleaning. |

Ready to achieve superior joint integrity and streamline your production process?

For high-volume manufacturing of complex or high-precision components, the controlled environment of furnace or vacuum brazing is unmatched. It ensures consistent, clean, and strong results batch after batch.

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed for reliable brazing processes. Our expertise helps laboratories and manufacturers optimize their joining operations for maximum efficiency and quality.

Contact our experts today to discuss how our solutions can enhance your brazing capabilities and meet your specific application needs.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Where is sinter used? A Guide to Its Critical Role in Manufacturing

- Which heat transfer can travel through the vacuum of space? Thermal Radiation Powers the Cosmos

- What are some of the most commonly used brazing metals? A Guide to Selecting the Right Filler Alloy

- What is the time of plasma nitriding? Optimize Your Cycle for Speed and Precision

- What temperature is needed to braze stainless steel? The critical guide to alloy-specific brazing

- What temperature is aluminum sintering? Master the 550°C-650°C Window for Strong Parts

- What role does a vacuum oven play in the drying process of ZIF-67 precursors? Ensure Purity for High-Quality Synthesis

- What is the primary function of a high-temperature annealing furnace in Ni-30Cr research? Master Alloy Homogenization