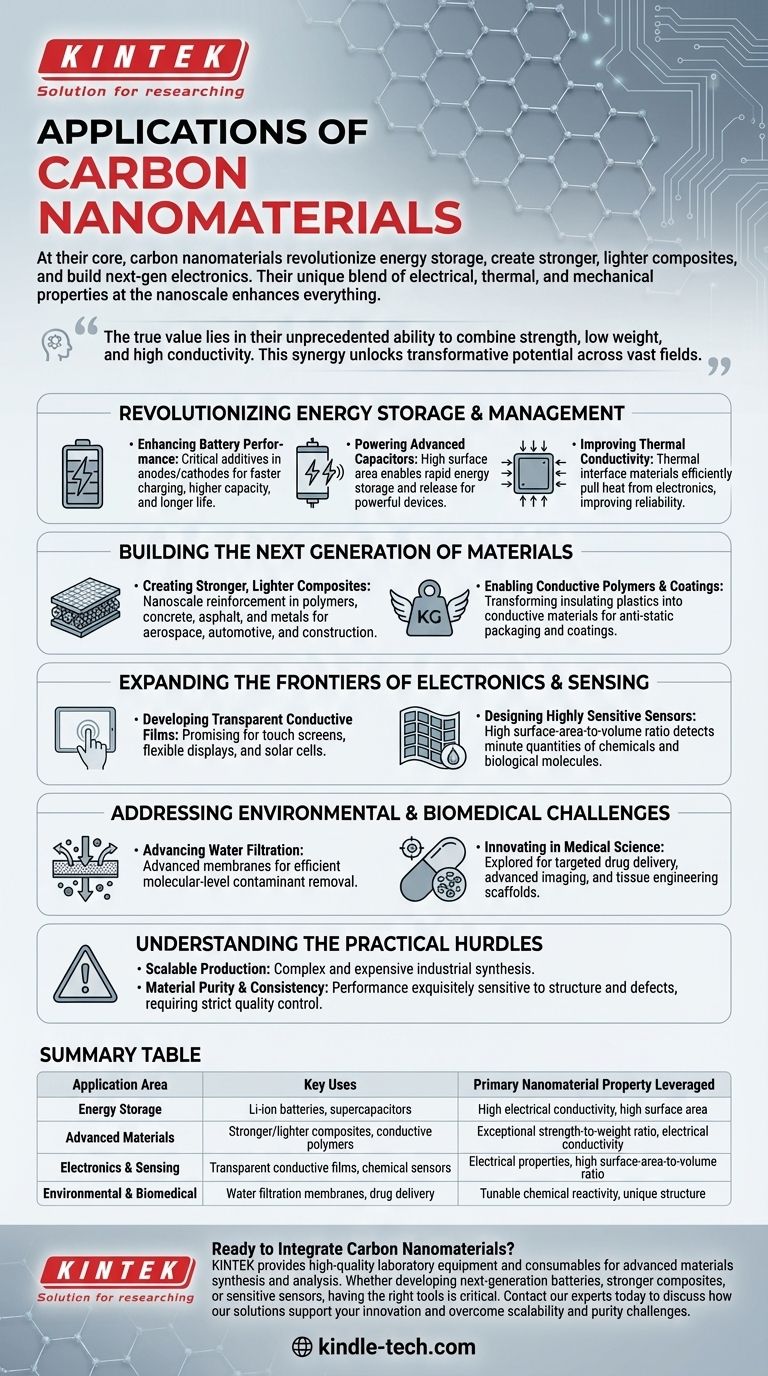

At their core, carbon nanomaterials are being applied to revolutionize energy storage, create stronger and lighter composite materials, and build the next generation of electronics and sensors. Their unique combination of electrical, thermal, and mechanical properties at the nanoscale allows them to enhance everything from lithium-ion batteries and reinforced concrete to transparent touch screens and biomedical devices.

The true value of carbon nanomaterials lies not in a single property, but in their unprecedented ability to combine strength, low weight, and high conductivity. This unique synergy is what unlocks their transformative potential across a vast range of industrial and scientific fields.

Revolutionizing Energy Storage and Management

One of the most significant impacts of carbon nanomaterials is in the field of energy. Their high surface area and excellent electrical conductivity directly address the core challenges of storing and managing electrical power more efficiently.

Enhancing Battery Performance

Carbon nanomaterials are critical additives in modern lithium-ion batteries. They are used in both the anode and cathode to improve electrical conductivity and structural integrity.

This enhancement allows batteries to charge faster, hold more energy, and endure more charge-discharge cycles without degrading.

Powering Advanced Capacitors

In supercapacitors, which require rapid energy storage and release, the incredibly high surface area of carbon nanomaterials is a key advantage. This property allows them to store significantly more charge than traditional materials, leading to more powerful energy storage devices.

Improving Thermal Conductivity

Effectively managing heat is a major bottleneck in modern electronics. Carbon nanomaterials are used to create thermal interface materials that efficiently pull heat away from sensitive components like computer processors, improving performance and reliability.

Building the Next Generation of Materials

By integrating carbon nanomaterials into existing materials, we can create composites with properties that were previously unattainable. They act as a nanoscale reinforcement, fundamentally changing the host material's characteristics.

Creating Stronger, Lighter Composites

When mixed into polymers, concrete, asphalt, or even metals, carbon nanomaterials create composites that are significantly stronger and more durable without adding significant weight.

This is a key application in aerospace, automotive (for fiber-reinforced polymers), and construction, where the strength-to-weight ratio is critical. They are even used to improve the durability of tires.

Enabling Conductive Polymers and Coatings

Most polymers are electrical insulators. By adding a small amount of carbon nanomaterials, these plastics can be transformed into conductive polymers. This is useful for applications like anti-static packaging for electronics and conductive coatings.

Expanding the Frontiers of Electronics and Sensing

The exceptional electrical properties and small size of carbon nanomaterials make them ideal candidates for innovating beyond the limits of traditional silicon-based electronics.

Developing Transparent Conductive Films

Carbon nanomaterials can be used to create films that are both electrically conductive and optically transparent. This makes them a promising material for next-generation touch screens, flexible displays, and solar cells.

Designing Highly Sensitive Sensors

The high surface-area-to-volume ratio of these materials makes them extremely sensitive to their surrounding environment. This enables the creation of highly advanced sensors capable of detecting minute quantities of specific chemicals or biological molecules.

Addressing Environmental and Biomedical Challenges

The unique physical and chemical properties of carbon nanomaterials are also being leveraged to solve complex problems in environmental remediation and medicine.

Advancing Water Filtration

Carbon nanomaterials can be fashioned into advanced membranes for wastewater treatment. Their structure allows them to filter out contaminants at a molecular level with high efficiency.

Innovating in Medical Science

In the biomedical field, researchers are exploring the use of carbon nanomaterials for targeted drug delivery, advanced imaging techniques, and as scaffolds for tissue engineering, opening new avenues for treatment and diagnostics.

Understanding the Practical Hurdles

While the potential applications are vast, the widespread adoption of carbon nanomaterials faces several real-world challenges that are important to acknowledge.

The Challenge of Scalable Production

Producing high-quality, uniform carbon nanomaterials at an industrial scale can be complex and expensive. The cost of synthesis remains a significant barrier for many bulk applications.

Ensuring Material Purity and Consistency

The performance of a nanomaterial is exquisitely sensitive to its structure and purity. Even minor defects or impurities can drastically alter its electrical or mechanical properties, making quality control a critical challenge.

Making the Right Choice for Your Goal

The application of carbon nanomaterials is dictated entirely by the specific property you need to leverage for your project.

- If your primary focus is energy innovation: Leverage their high surface area and electrical conductivity to improve the performance of batteries and supercapacitors.

- If your primary focus is materials science: Use them as a reinforcing additive to create stronger, lighter, and more durable composites for structural applications.

- If your primary focus is advanced electronics: Capitalize on their unique electrical properties to build next-generation sensors and transparent conductive films.

Ultimately, carbon nanomaterials provide a powerful new toolkit for engineering materials from the atom up, enabling us to solve some of our most pressing technological challenges.

Summary Table:

| Application Area | Key Uses | Primary Nanomaterial Property Leveraged |

|---|---|---|

| Energy Storage | Lithium-ion batteries, supercapacitors | High electrical conductivity, high surface area |

| Advanced Materials | Stronger/lighter composites, conductive polymers | Exceptional strength-to-weight ratio, electrical conductivity |

| Electronics & Sensing | Transparent conductive films, chemical sensors | Electrical properties, high surface-area-to-volume ratio |

| Environmental & Biomedical | Water filtration membranes, drug delivery | Tunable chemical reactivity, unique structure |

Ready to Integrate Carbon Nanomaterials into Your Research or Product Development?

KINTEK specializes in providing high-quality laboratory equipment and consumables essential for the synthesis, processing, and analysis of advanced materials like carbon nanomaterials. Whether you are developing next-generation batteries, stronger composites, or sensitive sensors, having the right tools is critical for success.

Contact our experts today to discuss how our solutions can support your innovation and help you overcome the challenges of scalability and purity in your nanomaterial applications.

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

People Also Ask

- Why is deposition uniformity a critical factor in device manufacturing? Ensuring Yield and Electrical Performance

- What is the purpose of using electrolytic polishing on copper foils? Optimize Your CVD Graphene & hBN Growth Surface

- What are sputtering targets? Essential for High-Quality Thin Film Deposition

- What are the applications of thin film semiconductor? From Microchips to Solar Energy

- What are the limitations of DC sputtering? Understanding Material Compatibility and Process Challenges

- What is flame synthesis method for carbon nanotubes? Scalable, Low-Cost Production for Industrial Applications

- What is the process of thin film optical coating? Precision Light Control for Lenses & Mirrors

- What are the disadvantages of RF sputtering? Navigating the Trade-offs of Thin Film Deposition