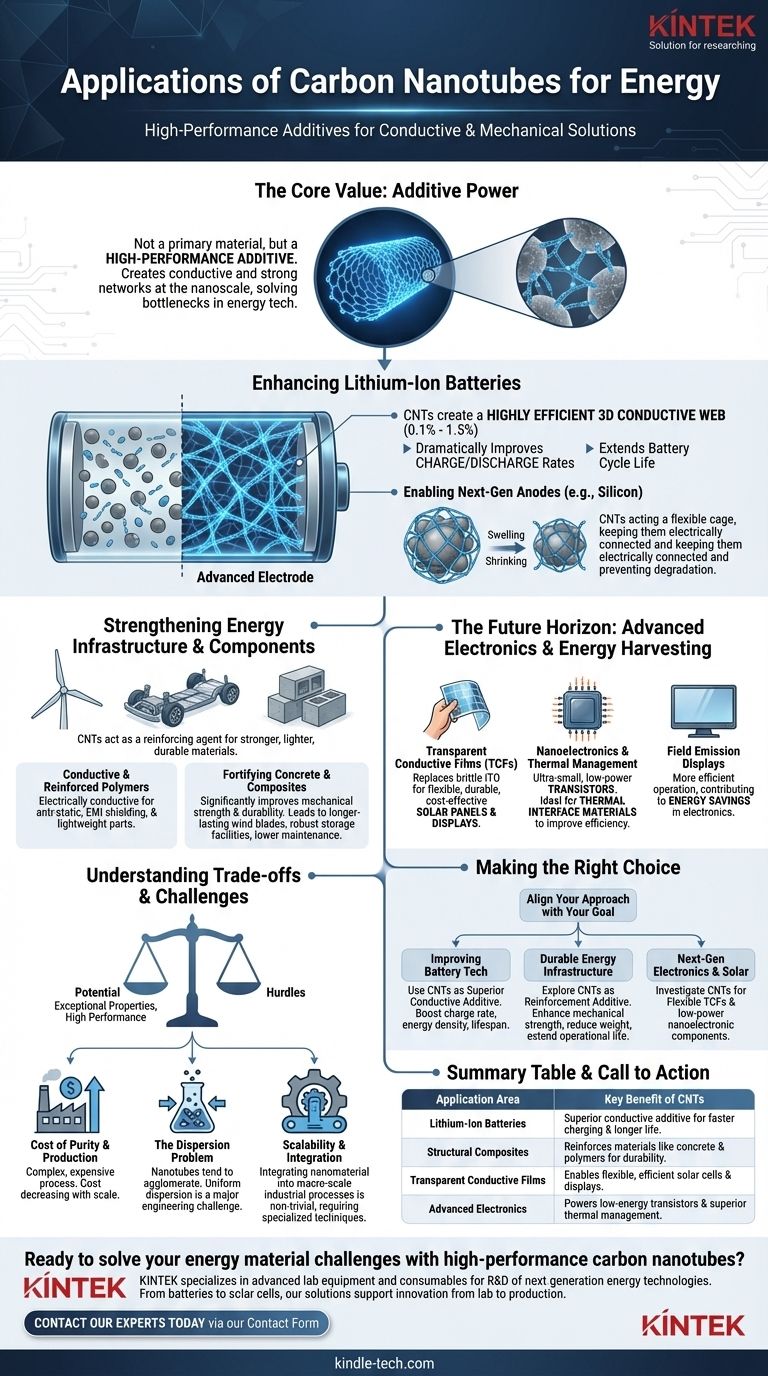

In the energy sector, carbon nanotubes (CNTs) are primarily valued for their exceptional electrical conductivity, mechanical strength, and unique nanoscale structure. Their most significant commercial application today is as a conductive additive in lithium-ion batteries. They are also being developed for use in structural composites for energy infrastructure, advanced electronics, and next-generation solar cells to improve efficiency and durability.

The core value of carbon nanotubes is not as a primary material, but as a high-performance additive. By creating electrically conductive and mechanically strong networks at the nanoscale, CNTs solve fundamental performance bottlenecks in existing energy technologies.

The Core Application: Enhancing Lithium-Ion Batteries

The most mature and impactful application of CNTs in the energy sector is within the electrodes of lithium-ion batteries. They serve as a superior replacement for traditional carbon black additives.

Why CNTs are Critical for Electrodes

Many active materials used in battery cathodes (like LFP) and anodes (like silicon) have inherently poor electrical conductivity. This limits how quickly a battery can be charged and discharged and reduces its overall efficiency.

How CNTs Create Conductive Pathways

Even at very low concentrations (0.1% to 1.5%), CNTs form a highly efficient, three-dimensional conductive web throughout the electrode. This network provides a superhighway for electrons, ensuring they can reach every active material particle.

This dramatically improves charge/discharge rates, increases energy density, and extends the battery's cycle life by ensuring more uniform electrochemical reactions.

Enabling Next-Generation Anodes

CNTs are crucial for enabling high-capacity silicon anodes. Silicon can store much more energy than traditional graphite, but it swells and shrinks dramatically during cycling, causing the electrode to degrade. The strong and flexible CNT network helps hold the silicon particles together and maintains electrical contact, solving this critical failure point.

Strengthening Energy Infrastructure and Components

CNTs act as a reinforcing agent in composites, creating materials that are stronger, lighter, and more durable for demanding energy applications.

Conductive and Reinforced Polymers

Adding CNTs to polymers can make them electrically conductive. This is essential for applications like anti-static or EMI-shielding enclosures for sensitive electronics and lightweight conductive parts used in vehicles or machinery.

Fortifying Concrete and Composites

In infrastructure, CNTs can significantly improve the mechanical strength and durability of materials like concrete or fiber-reinforced polymers. This could lead to longer-lasting wind turbine blades, more robust energy storage facilities, and more resilient infrastructure with lower lifetime maintenance costs.

The Future Horizon: Advanced Electronics and Energy Harvesting

The unique electronic properties of CNTs position them as a key material for next-generation, low-power devices and energy harvesting systems.

Transparent Conductive Films (TCFs)

CNTs can be used to create films that are both transparent and electrically conductive. These films are a potential replacement for the brittle and expensive indium tin oxide (ITO) used today in solar cells and displays, enabling more flexible, durable, and cost-effective solar panels.

Nanoelectronics and Thermal Management

The exceptional properties of CNTs allow for the creation of ultra-small, highly efficient transistors that consume less power. Their high thermal conductivity also makes them ideal for thermal interface materials, which help dissipate waste heat from high-power electronics, improving overall energy efficiency.

Field Emission Displays

CNTs can be deposited on glass to create highly efficient field emission displays. These devices require less energy to operate compared to conventional display technologies, contributing to energy savings in consumer and industrial electronics.

Understanding the Trade-offs and Challenges

Despite their immense potential, the widespread adoption of carbon nanotubes faces several practical hurdles that are critical to understand.

The Cost of Purity and Production

Manufacturing high-purity, defect-free CNTs remains a complex and relatively expensive process. The cost has been a significant barrier to their use in bulk applications, though it is steadily decreasing as production scales.

The Dispersion Problem

By their nature, nanotubes tend to clump together (or agglomerate) due to powerful van der Waals forces. Poor dispersion in a host material (like a polymer or battery slurry) can negate their benefits and even create defects. Achieving uniform dispersion is a major engineering challenge.

Scalability and Integration

Integrating a nanoscale material into macro-scale industrial manufacturing processes is not trivial. It often requires specialized equipment and new processing techniques, which can slow down adoption and increase initial implementation costs.

Making the Right Choice for Your Goal

To effectively leverage CNTs, you must align your approach with the specific performance goal you are trying to achieve.

- If your primary focus is improving existing battery technology: Use CNTs as a superior conductive additive to boost the charge rate, energy density, and lifespan of both current and next-generation electrode materials.

- If your primary focus is durable energy infrastructure: Explore CNTs as a reinforcement additive in composites and concrete to enhance mechanical strength, reduce weight, and extend the operational life of critical assets.

- If your primary focus is next-generation electronics and solar: Investigate CNTs for their potential in creating flexible transparent conductive films and ultra-efficient, low-power nanoelectronic components.

Ultimately, leveraging carbon nanotubes is about using their unique nanoscale properties to solve macro-level energy challenges.

Summary Table:

| Application Area | Key Benefit of CNTs |

|---|---|

| Lithium-Ion Batteries | Superior conductive additive for faster charging & longer life |

| Structural Composites | Reinforces materials like concrete & polymers for durability |

| Transparent Conductive Films | Enables flexible, efficient solar cells & displays |

| Advanced Electronics | Powers low-energy transistors & superior thermal management |

Ready to solve your energy material challenges with high-performance carbon nanotubes?

KINTEK specializes in providing advanced lab equipment and consumables for the research and development of next-generation energy technologies. Whether you are developing higher-capacity batteries, more durable composites, or efficient solar cells, our solutions support your innovation from lab to production.

Contact our experts today via our Contact Form to discuss how we can help you integrate carbon nanotubes into your energy applications.

Visual Guide

Related Products

- Aluminum Foil Current Collector for Lithium Battery

- High Purity Zinc Foil for Battery Lab Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How does ultra-low temperature laboratory equipment support reliability testing for batteries in extreme cold?

- Why is vacuum heating dehydration necessary for ionic liquid electrolytes? Optimize Sodium Battery Performance

- What role does a drying oven play in the preparation of NCM523 composite cathodes? Optimize Your Battery Performance

- How should carbon cloth used for high-temperature electrolysis be handled after operation? Prevent Irreversible Oxidative Damage

- What is the purpose of the stepwise pressing process for solid-state batteries? Achieve Low-Impedance Interfaces

- Why is precise control critical for Li6PS5Cl synthesis? Master Temperature & Atmosphere for Solid Electrolytes

- What are the advantages of using a thermostatic control chamber for flow batteries? Achieve Superior Data Integrity

- How does a dry impact-blending device facilitate the preparation of composite particles? Solvent-Free Coating Innovation