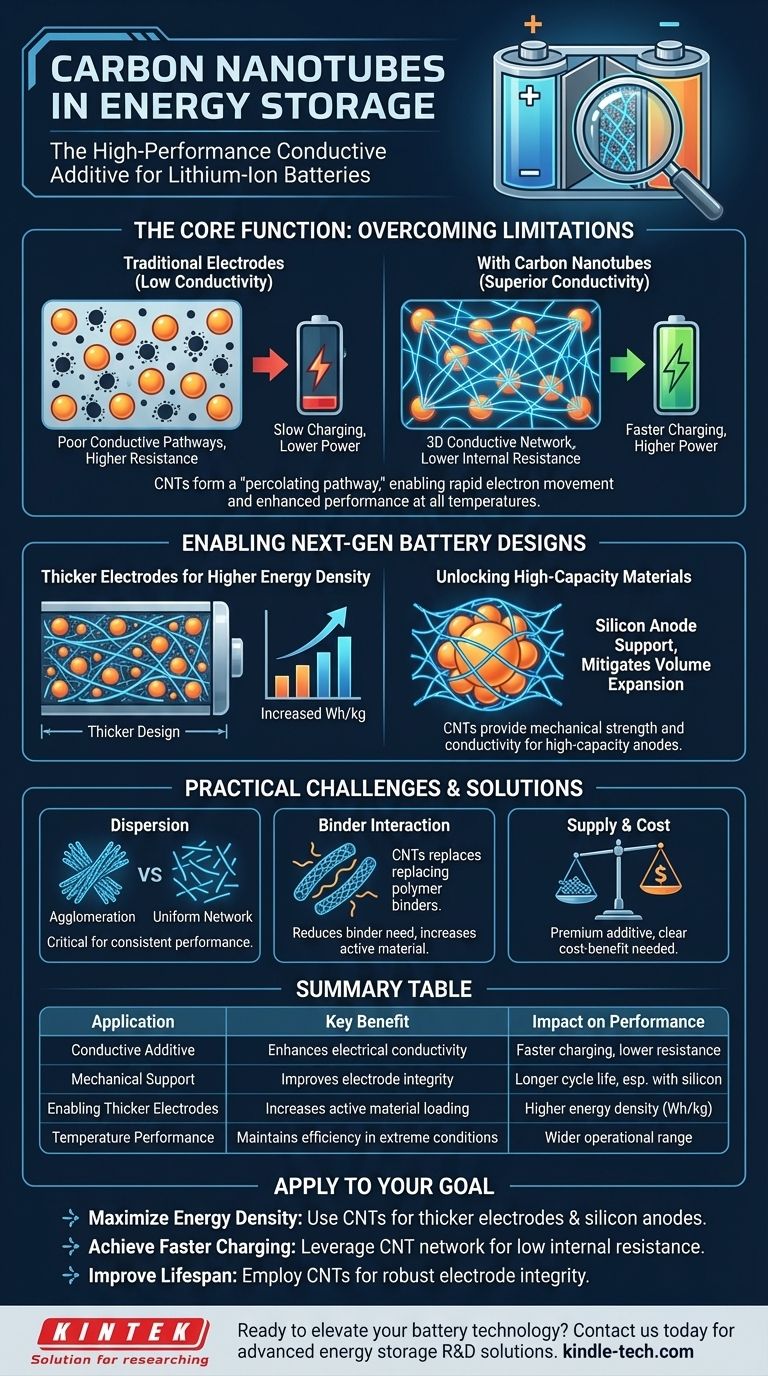

In energy storage, the single most significant application for carbon nanotubes (CNTs) is as a high-performance conductive additive in the electrodes of lithium-ion batteries. By incorporating even a small percentage of CNTs, manufacturers can dramatically improve electrical conductivity and mechanical resilience, which in turn unlocks higher energy density, faster charging speeds, and a wider operational temperature range.

Carbon nanotubes are not a replacement for the primary energy-storing materials in a battery. Instead, they act as a critical enabler—an internal scaffolding that creates a highly efficient electrical and mechanical network, allowing for thicker, more powerful electrode designs that were previously impractical.

The Core Function: Overcoming Electrode Limitations

The active materials used in battery electrodes, such as silicon in anodes or NMC in cathodes, are excellent at storing lithium ions but are often poor electrical conductors. This inherent limitation creates a bottleneck that slows down performance.

The Problem of Low Conductivity

Traditional electrodes rely on additives like carbon black to create conductive pathways. However, these materials require higher loadings and are less effective at forming a robust, long-range network, which limits the electrode's thickness and power capability.

How CNTs Provide a Solution

Due to their extreme aspect ratio (very long and thin) and exceptional electrical conductivity, CNTs form a superior, three-dimensional conductive network throughout the electrode. A tiny amount of CNTs can create a "percolating pathway," much like steel rebar reinforces a large volume of concrete.

This network drastically lowers the electrode's internal resistance, ensuring electrons can move quickly and efficiently to and from the active material during charging and discharging.

The Impact on Performance

Lower internal resistance directly translates to better rate capability, meaning the battery can be charged and discharged faster with less energy lost as heat. This improved conductivity also enhances performance at both low and high temperatures.

Enabling Next-Generation Battery Designs

The true value of carbon nanotubes lies in their ability to enable designs that push the boundaries of energy storage. They solve not just an electrical problem but also a mechanical one.

Thicker Electrodes for Higher Energy Density

The most straightforward way to increase a battery's energy capacity is to make the electrodes thicker, packing in more active material. CNTs provide the essential electronic conductivity and mechanical strength required to make these thick electrodes viable, directly boosting the energy density (Wh/kg) of the cell.

Unlocking High-Capacity Materials

Next-generation anode materials like silicon promise a massive leap in energy capacity. However, they suffer from extreme volume expansion during charging, which quickly destroys the electrode and kills the battery's cycle life. The flexible and strong CNT network helps bind the electrode together, accommodating this stress and significantly improving durability.

Optimizing Both Cathode and Anode

The benefits of CNTs are not limited to one side of the battery. They are increasingly used in both anodes and cathodes to enhance conductivity, improve mechanical integrity, and enable the use of more advanced active materials across the entire cell.

Understanding the Trade-offs and Practical Challenges

While CNTs offer significant advantages, their implementation is not a simple drop-in process. Success requires addressing key manufacturing and formulation challenges.

The Critical Challenge of Dispersion

Carbon nanotubes have a strong tendency to bundle together, a phenomenon known as agglomeration. If they are not properly dispersed into a uniform network within the electrode slurry, they can create defects and lead to inconsistent, poor performance. Achieving good dispersion is a primary focus of battery R&D.

Binder Interaction and Formulation

CNTs can reduce or, in some cases, eliminate the need for traditional polymer binders that hold the electrode together. While this can further increase energy density, it requires a complete redesign of the electrode slurry chemistry, moving from a simple additive to a core structural component.

Supply Chain and Cost

As a specialized, high-performance material, the cost and supply chain for battery-grade CNTs are critical considerations. While prices are decreasing as adoption grows, they remain a premium additive compared to conventional carbon black, requiring a clear cost-benefit justification.

How to Apply This to Your Goal

The decision to use CNTs should be driven by a specific performance target.

- If your primary focus is maximizing energy density: Use CNTs to enable thicker electrodes and to help manage the mechanical stress of high-capacity silicon anodes.

- If your primary focus is achieving faster charging: Leverage the highly conductive CNT network to minimize internal resistance and heat generation during high-power operation.

- If your primary focus is improving battery lifespan and reliability: Employ the robust mechanical properties of CNTs to maintain electrode integrity through thousands of charge cycles, especially when using materials prone to expansion.

Ultimately, carbon nanotubes serve as a key enabling technology, unlocking performance gains that are fundamental to the future of energy storage.

Summary Table:

| Application | Key Benefit | Impact on Battery Performance |

|---|---|---|

| Conductive Additive | Enhances electrical conductivity | Faster charging, lower resistance |

| Mechanical Support | Improves electrode integrity | Longer cycle life, especially with silicon anodes |

| Enabling Thicker Electrodes | Increases active material loading | Higher energy density (Wh/kg) |

| Temperature Performance | Maintains efficiency in extreme conditions | Wider operational range |

Ready to elevate your battery technology with carbon nanotubes? KINTEK specializes in providing high-quality lab equipment and consumables tailored for advanced energy storage R&D. Whether you're developing next-generation lithium-ion batteries or optimizing electrode formulations, our solutions help you achieve superior performance and reliability. Contact us today to discuss how we can support your innovation goals!

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- High Purity Zinc Foil for Battery Lab Applications

- Aluminum Foil Current Collector for Lithium Battery

- Electrode Polishing Material for Electrochemical Experiments

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites

- What are the common applications for carbon cloth? Unlock Its Potential in Energy & Electrochemical Systems

- How should carbon cloth used for high-temperature electrolysis be handled after operation? Prevent Irreversible Oxidative Damage

- What are the four main types of sensors? A Guide to Power Source and Signal Type