In essence, Physical Vapor Deposition (PVD) is a cornerstone technology for applying high-performance thin films across a vast range of industries. Its applications span from aerospace and microelectronics to medical devices and industrial tools, where it is used to enhance durability, add specific optical or electrical properties, and protect components from harsh environments.

The core value of PVD lies in its ability to deposit exceptionally pure, dense, and high-performance thin coatings onto a substrate within a vacuum. This control over the film's properties is what makes it indispensable for manufacturing advanced components.

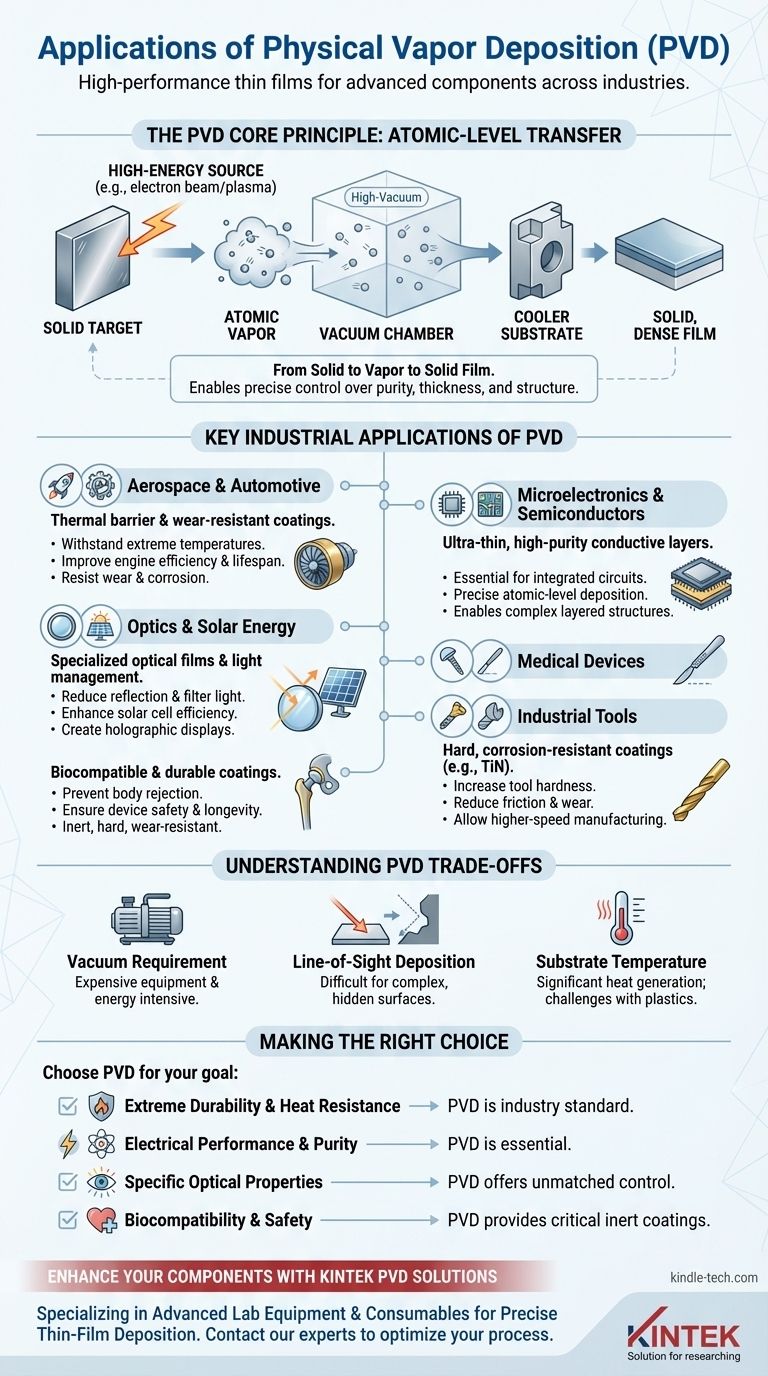

The Core Principle: Why PVD is So Versatile

Physical Vapor Deposition is fundamentally a process of transferring a material on an atomic level. It is a "physical" process because the material changes its physical state—from solid to vapor and back to solid—without undergoing a chemical reaction.

From Solid to Vapor

The process begins in a high-vacuum chamber containing the material to be deposited, known as the target. A high-energy source, such as an electron beam or plasma, strikes the target with immense force.

This energy transforms the solid material directly into a vapor, releasing individual atoms or molecules.

From Vapor to Solid Film

These vaporized atoms then travel through the vacuum chamber and strike the object being coated, which is called the substrate. Upon contact with the cooler substrate, the vapor rapidly condenses, forming a thin, dense, and highly-adherent solid film.

This entire process allows for incredible control over the coating's purity, thickness, and structure.

Key Industrial Applications of PVD

The precision of PVD allows engineers to tailor surface properties for specific performance goals. This versatility has led to its adoption in nearly every high-tech industry.

Aerospace and Automotive

In aerospace, PVD is used to apply dense, temperature-resistant coatings to engine components. These films act as thermal barriers, allowing parts to withstand extreme temperatures and improving engine efficiency and lifespan.

For automotive parts, PVD provides durable coatings that resist wear and corrosion, extending the life of critical components.

Microelectronics and Semiconductors

The manufacturing of integrated circuits and semiconductors relies heavily on PVD. It is used to deposit the ultra-thin, high-purity conductive layers of metal required to build microscopic circuits.

Its precision is essential for creating the complex, layered structures found in modern microprocessors and memory chips.

Optics and Solar Energy

PVD is used to apply specialized optical films to lenses, glass, and solar panels. These coatings can reduce reflection, filter specific wavelengths of light, or, in the case of solar cells, enhance light absorption to improve efficiency.

It is also used to create holographic displays and other advanced optical components.

Medical Devices

For medical implants and surgical tools, biocompatibility and durability are critical. PVD is used to apply inert, hard, and wear-resistant coatings that prevent rejection by the body and ensure the longevity and safety of the device.

Industrial Tools

One of the most common applications is applying hard, corrosion-resistant coatings to cutting tools, drills, and dies. Coatings like Titanium Nitride (TiN) dramatically increase tool hardness and lubricity, reducing wear and allowing for higher-speed manufacturing operations.

Understanding the Trade-offs

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

Requirement for Vacuum

The entire PVD process must take place in a high-vacuum chamber. This equipment is expensive and requires significant energy, making the process more costly than some conventional coating methods like electroplating.

Line-of-Sight Deposition

Most PVD processes are "line-of-sight," meaning the vaporized atoms travel in a straight line from the target to the substrate. This can make it difficult to achieve a uniform coating on complex, three-dimensional shapes with hidden surfaces or deep crevices.

Substrate Temperature

The PVD process generates significant heat, which can be a limitation for temperature-sensitive substrates like plastics. While low-temperature PVD processes exist, they present their own set of engineering challenges.

Making the Right Choice for Your Goal

Selecting a coating technology depends entirely on the primary performance requirement for your component.

- If your primary focus is extreme durability and heat resistance: PVD is the industry standard for aerospace components and high-performance cutting tools.

- If your primary focus is electrical performance and purity: PVD is essential for depositing the precise, thin conductive films required in semiconductors and microelectronics.

- If your primary focus is specific optical properties: PVD offers unmatched control for applying anti-reflective or light-filtering films for lenses and solar cells.

- If your primary focus is biocompatibility: PVD provides inert, safe, and durable coatings critical for medical implants and surgical instruments.

Ultimately, PVD is a foundational technology for engineering materials at the atomic level to achieve superior performance.

Summary Table:

| Industry | Key PVD Application | Primary Benefit |

|---|---|---|

| Aerospace & Automotive | Thermal barrier coatings on engine parts | Extreme temperature resistance & durability |

| Microelectronics | Conductive layers for circuits | High-purity, precise thin films |

| Optics & Solar Energy | Anti-reflective & light-absorption films | Enhanced optical performance & efficiency |

| Medical Devices | Biocompatible coatings on implants | Wear resistance & safety |

| Industrial Tools | Hard coatings like Titanium Nitride (TiN) | Increased tool hardness & lifespan |

Ready to enhance your components with high-performance PVD coatings?

At KINTEK, we specialize in advanced lab equipment and consumables for precise thin-film deposition. Whether you're developing cutting-edge semiconductors, durable aerospace components, or life-saving medical devices, our solutions are designed to meet the stringent demands of your industry.

We provide:

- State-of-the-art PVD systems for R&D and production.

- Expert technical support to optimize your coating process.

- High-purity targets and consumables for consistent results.

Let's discuss how our expertise can help you achieve superior material performance. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition