At their core, presses are fundamental tools used across countless industries to shape, bond, test, or compact materials through the application of controlled force. Their applications range from large-scale industrial manufacturing, such as forming car parts and crushing vehicles, to precise laboratory work like creating pharmaceutical pellets and testing the properties of novel materials.

The true value of a press lies not just in its power, but in its versatility. By controlling pressure, and sometimes heat, this single technology enables everything from mass production and material analysis to research and development.

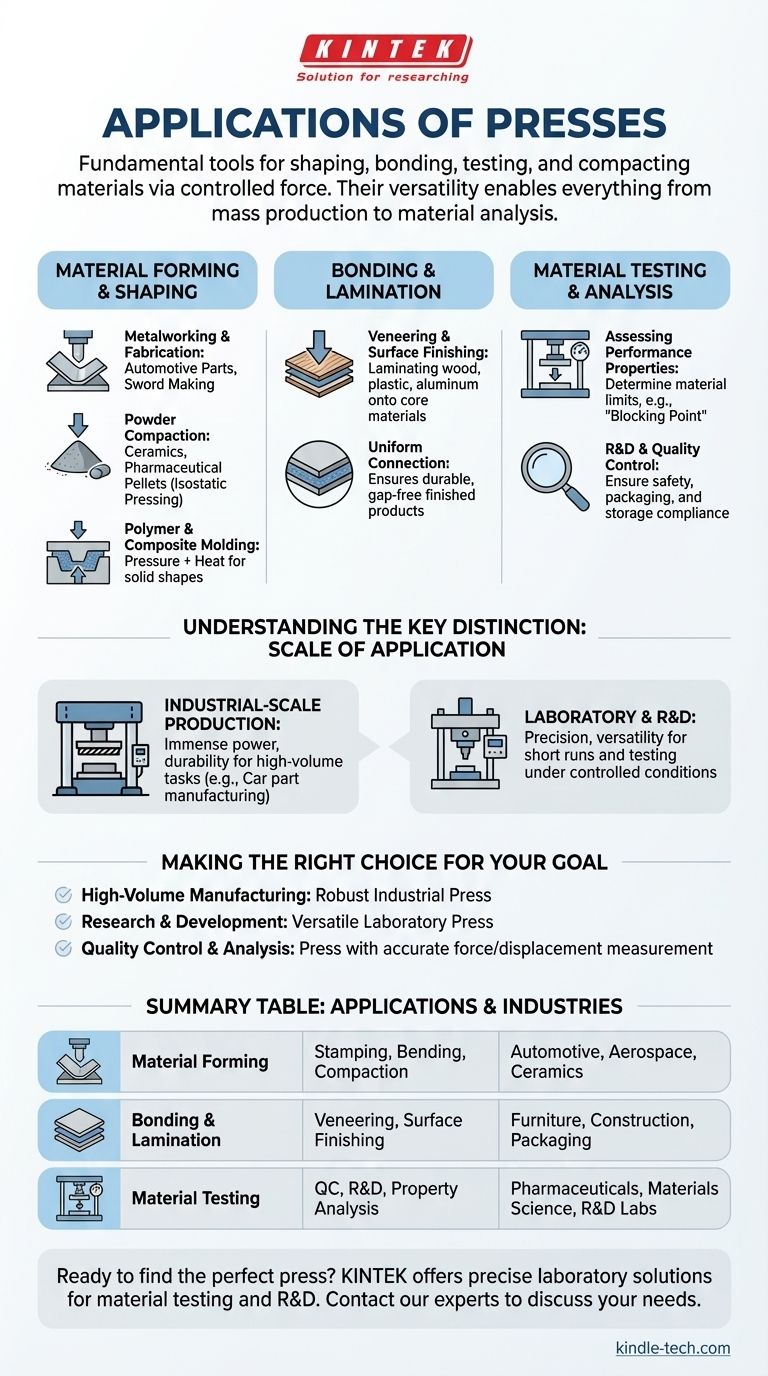

Material Forming and Shaping

The most common application of a press is to physically alter the shape of a material. This is achieved by applying force that exceeds the material's ability to resist deformation, forcing it into a new, desired form.

Metalworking and Fabrication

Presses are essential in metalworking for tasks that require immense force. Electric and hydraulic presses are used for stamping, bending, and forming metal sheets into components.

This includes manufacturing automotive parts, structural components, and even historical recreations like sword making.

Powder Compaction

Many materials begin as powders, and presses are used to compact them into a solid form. This process is critical in multiple fields.

Isostatic presses apply uniform pressure from all directions, which is ideal for creating complex shapes from powdered metals or ceramics. This is also the principle behind making pharmaceutical pellets and testing concrete samples.

Polymer and Composite Molding

For polymers and composites, presses often combine pressure and heat. This melts the raw material, such as a powder or resin, allowing it to flow and fill a mold before being compressed into its final, solid shape.

Bonding and Lamination

Beyond changing the shape of a single material, presses are also used to bond different layers together. The pressure ensures a tight, uniform connection between surfaces.

Veneering and Surface Finishing

Specialized veneer presses are used to laminate materials like wood veneer, plastic laminate, or even thin aluminum sheets onto a core material, such as a particleboard or a door.

The pressure guarantees that the adhesive spreads evenly and the layers are bonded without gaps, creating a durable and finished product.

Material Testing and Analysis

In research and quality control, presses are not used to create a final product but to understand a material's limits. This is a critical function for ensuring safety and performance.

Assessing Performance Properties

A press can precisely measure a material's response to force. For example, it can determine the "blocking point" of a printed material by pressing samples together until they adhere.

This test reveals how a material might deform or stick together when stacked, which is vital information for packaging, storage, and transport. This type of analysis is a cornerstone of R&D and quality assurance.

Understanding the Key Distinction: Scale of Application

The term "press" covers a wide range of equipment. The primary difference lies in the scale and precision required for the task. Understanding this distinction is key to grasping their full range of applications.

Industrial-Scale Production

In settings like car part manufacturing or vehicle crushing, massive hydraulic presses are used. Their primary attributes are immense power and durability, designed for repetitive, high-volume tasks.

Laboratory and R&D

In contrast, laboratory presses are built for precision and versatility. They are used for R&D, material testing, and short production runs. These presses allow researchers to create small, consistent samples and test specimens under tightly controlled conditions.

Making the Right Choice for Your Goal

To apply this knowledge, consider the primary objective of the work being done.

- If your primary focus is high-volume manufacturing: You need a robust, industrial-scale hydraulic or electric press designed for a specific forming, stamping, or crushing task.

- If your primary focus is research and development: A versatile laboratory press that offers precise control over both pressure and temperature is the appropriate tool for creating samples and prototypes.

- If your primary focus is quality control and material analysis: You require a press equipped to measure force and displacement accurately to test properties like compressive strength or blocking resistance.

Ultimately, understanding the application of controlled pressure is fundamental to innovating and producing nearly every physical product in the modern world.

Summary Table:

| Application Area | Key Functions | Common Industries |

|---|---|---|

| Material Forming | Stamping, bending, powder compaction | Automotive, Aerospace, Ceramics |

| Bonding & Lamination | Veneering, surface finishing | Furniture, Construction, Packaging |

| Material Testing | Quality control, R&D, property analysis | Pharmaceuticals, Materials Science, R&D Labs |

Ready to find the perfect press for your application? Whether you're in high-volume manufacturing or precision R&D, KINTEK's expertise in lab equipment and consumables ensures you get the right solution. Our laboratory presses offer the precise control and reliability needed for material testing, sample preparation, and prototyping. Contact our experts today to discuss how we can support your laboratory's specific needs and enhance your operational efficiency.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Warm Isostatic Press for Solid State Battery Research

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

People Also Ask

- What are the advantages and disadvantages of transfer moulding? Achieve Precision for Complex Thermoset Parts

- What role does a large hydraulic press play in the cold working process of TT 690 alloy? Precision SCC Research Support

- What is XRF sample preparation? Achieve Accurate and Reliable Elemental Analysis

- Why is a laboratory hydraulic press required for cold pressing? Unlock Solid-State Battery Performance

- What is the history of the hydraulic press? From Pascal's Principle to Industrial Revolution Powerhouse

- How do you press wood pellets? Master the Process of High-Pressure Pelletizing

- What is an industrial hydraulic press? Harness Immense Force for Precision Manufacturing

- What is the limitation of XRF? Understanding the Key Constraints for Accurate Analysis