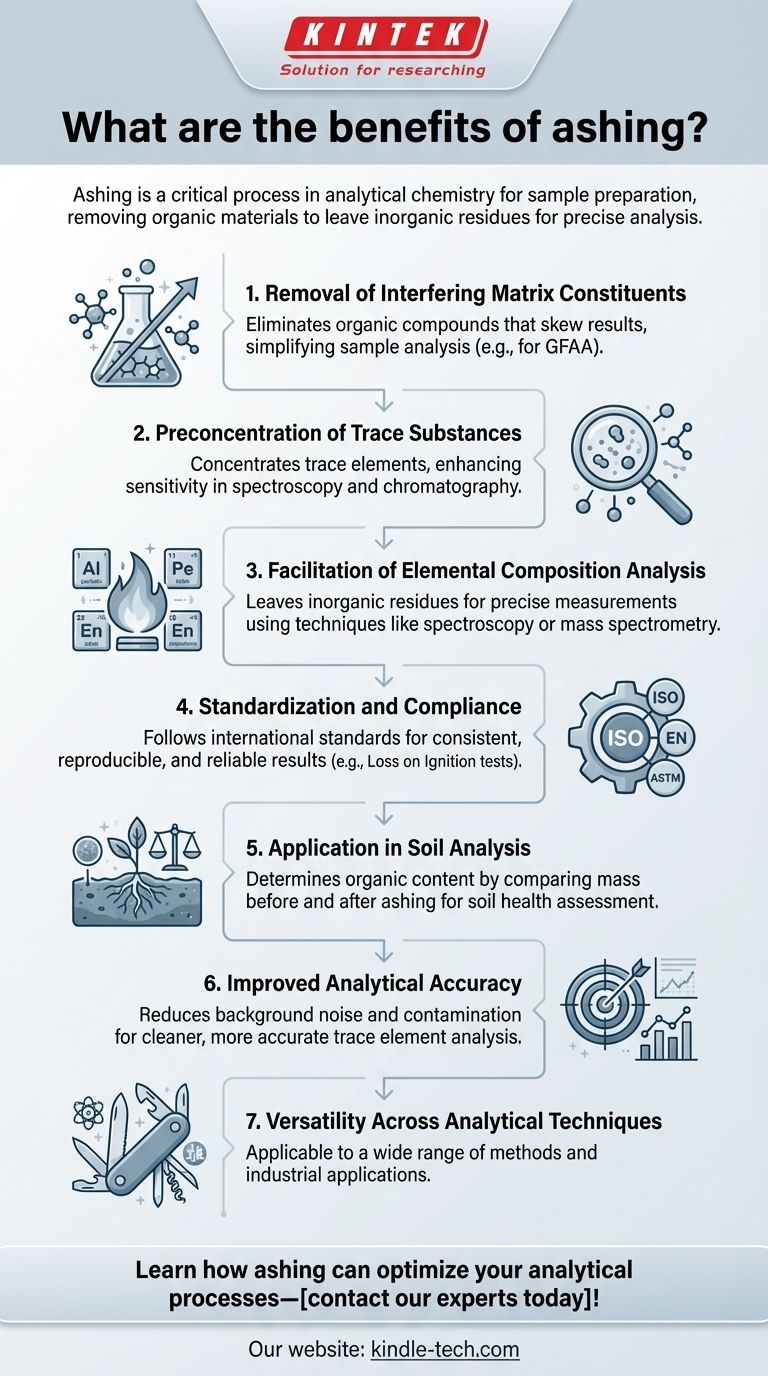

Ashing is a critical process in analytical chemistry, particularly for sample preparation in techniques like spectroscopy and chromatography. It involves heating a sample to remove organic materials, leaving behind inorganic residues (ash) for further analysis. The primary benefits of ashing include the removal of interfering matrix constituents, preconcentration of trace substances, and enabling accurate elemental analysis. This process is governed by international standards and is widely used in fields such as soil analysis, where it helps determine organic content by comparing mass before and after ashing. By eliminating unwanted materials, ashing ensures cleaner, more precise analytical results.

Key Points Explained:

-

Removal of Interfering Matrix Constituents

- Ashing eliminates organic compounds and other matrix components that could interfere with the measurement of analytes.

- This is particularly important in techniques like graphite furnace atomic absorption (GFAA) spectroscopy, where matrix interference can skew results.

- By oxidizing organic materials, the process leaves behind inorganic residues, simplifying the sample for analysis.

-

Preconcentration of Trace Substances

- Ashing serves as a mineralization step, concentrating trace elements or substances in the sample.

- This preconcentration is crucial for detecting low levels of analytes in techniques like chromatography or spectroscopy.

- By reducing the sample to its inorganic components, ashing enhances the sensitivity and accuracy of subsequent analyses.

-

Facilitation of Elemental Composition Analysis

- The residual ash from the ashing process contains non-combustible, inorganic compounds that are easier to analyze.

- This makes ashing a valuable step for determining the elemental composition of a sample.

- Techniques like optical spectroscopy or mass spectrometry can then be applied to the ash residue for precise measurements.

-

Standardization and Compliance

- Ashing processes are often governed by international standards such as ISO, EN, or ASTM.

- These standards ensure consistency, reproducibility, and reliability across different laboratories and industries.

- For example, Loss on Ignition (LOI) tests, which involve weighing samples before and after ashing, are standardized methods for determining mass reduction.

-

Application in Soil Analysis

- Ashing is widely used in soil science to determine the organic content of soil samples.

- By comparing the mass of the sample before and after ashing, researchers can calculate the proportion of organic matter.

- This information is vital for understanding soil health, fertility, and suitability for agricultural or environmental purposes.

-

Improved Analytical Accuracy

- By removing unwanted organic materials, ashing reduces background noise and interference in analytical instruments.

- This leads to cleaner, more accurate results, especially in trace element analysis.

- The process also minimizes the risk of contamination, ensuring that the final analysis reflects the true composition of the sample.

-

Versatility Across Analytical Techniques

- Ashing is applicable to a wide range of analytical methods, including spectroscopy, chromatography, and elemental analysis.

- Its adaptability makes it a fundamental step in various scientific and industrial applications, from environmental testing to material science.

By addressing these key points, the benefits of ashing become clear: it enhances the accuracy, sensitivity, and reliability of analytical results while simplifying sample preparation and ensuring compliance with international standards.

Summary Table:

| Key Benefit | Description |

|---|---|

| Removal of Interfering Matrix Constituents | Eliminates organic compounds that skew results, simplifying sample analysis. |

| Preconcentration of Trace Substances | Concentrates trace elements, enhancing sensitivity in spectroscopy and chromatography. |

| Facilitation of Elemental Composition | Leaves inorganic residues for precise elemental analysis. |

| Standardization and Compliance | Follows ISO, EN, and ASTM standards for consistent, reliable results. |

| Application in Soil Analysis | Determines organic content by comparing mass before and after ashing. |

| Improved Analytical Accuracy | Reduces background noise and contamination for cleaner, more accurate results. |

| Versatility Across Techniques | Applicable to spectroscopy, chromatography, and elemental analysis. |

Learn how ashing can optimize your analytical processes—contact our experts today!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the technical advantages of using a laboratory vacuum oven for drying MXene nanopowders? | KINTEK

- What are the conditions for sintering? Achieve Optimal Material Density and Strength

- What is the method of heat treatment to steel? A Guide to Engineering Material Performance

- How does a high-temperature box resistance furnace assist in PBF annealing? Optimize Stress Relief and Microstructure

- What is the primary role of a constant temperature oven in preparing thermochemical energy storage materials?

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab

- What is the function of a laboratory oven in W18Cr4V steel sample preparation? Expert Microstructural Drying Guide

- How are ceramics sintered? Mastering the High-Temperature Process for Stronger Materials