In short, furnace brazing offers a superior method for creating strong, clean, and dimensionally accurate joints, especially for complex assemblies or dissimilar materials. By precisely controlling the entire thermal cycle in a protective atmosphere, it avoids the distortion common in welding, eliminates the need for corrosive fluxes and extensive post-processing, and allows for designs that would otherwise be impossible to manufacture.

The core value of furnace brazing is not just joining parts, but enabling the creation of high-integrity, complex components at scale. It transforms metal joining from a simple fabrication step into a highly controlled, value-added manufacturing process.

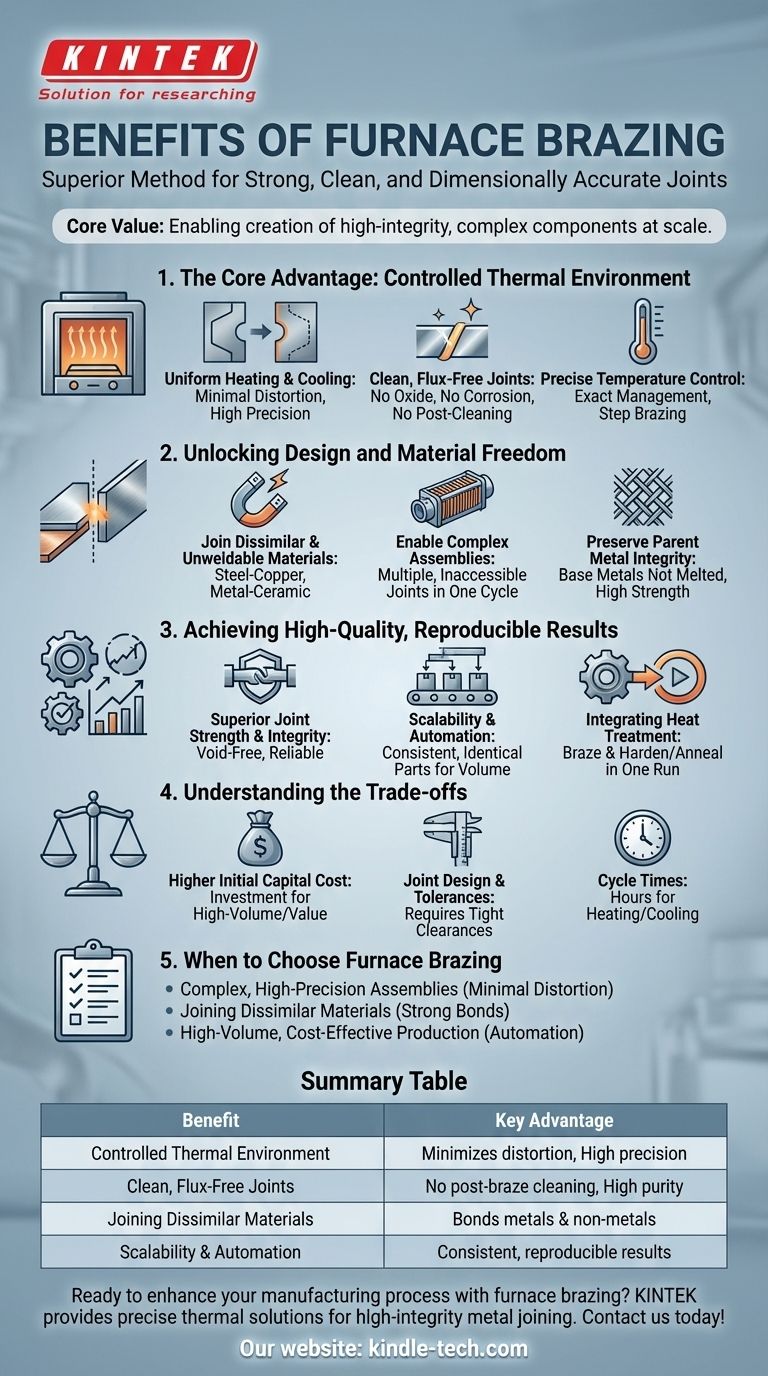

The Core Advantage: A Controlled Thermal Environment

The primary benefits of furnace brazing all stem from one fundamental principle: the entire assembly is heated and cooled in a highly controlled, uniform manner within an enclosed chamber.

Uniform Heating and Cooling

Because the entire part is brought to temperature slowly and evenly, thermal stresses are drastically minimized. This virtually eliminates the warping and distortion that often plague welded assemblies, making furnace brazing ideal for high-precision components with tight tolerances.

Clean, Flux-Free Joints

Furnace brazing is typically performed in a vacuum or a controlled, oxygen-free atmosphere. This environment prevents the formation of oxides on the metal surfaces during heating. As a result, there is no need for corrosive chemical fluxes, which in turn eliminates the need for intensive post-braze cleaning and removes a major source of potential joint contamination and failure.

Precise Temperature Control

Furnace controls allow for exact temperature management throughout the cycle. This precision makes it possible to perform "step brazing," where multiple joints on the same assembly are brazed sequentially using filler metals with different melting points.

Unlocking Design and Material Freedom

This controlled process provides engineers with capabilities that other joining methods cannot match, opening the door to more innovative and efficient designs.

Joining Dissimilar and Unweldable Materials

Brazing occurs below the melting point of the parent materials. This allows for the joining of vastly different metals, such as steel to copper, or even non-metallic materials like ceramics to metal. These combinations are often impossible to join via welding.

Enabling Complex Assemblies

Furnace brazing excels at creating multiple joints at once. A single cycle can braze hundreds of joints on a complex assembly, including those that are long, inaccessible, or impossible to reach with a welding torch. This makes it possible to manufacture intricate parts like heat exchangers in a single, efficient step.

Preserving Parent Metal Integrity

Since the base metals are never melted, their fundamental metallurgical properties remain intact. The brazed joint, formed by the filler metal flowing into the gap via capillary action, is exceptionally strong and can even exceed the strength of the parent materials.

Achieving High-Quality, Reproducible Results

For manufacturing operations, furnace brazing delivers consistency, quality, and efficiency that drive down total costs.

Superior Joint Strength and Integrity

The controlled, flux-free environment produces extremely clean, high-integrity joints that are free of voids and contamination. This leads to superior mechanical performance and reliability under stress.

Scalability and Automation

Once a thermal profile is established, it can be repeated perfectly for thousands of parts. The process does not depend on the skill of a manual operator, ensuring that every assembly is identical. This makes it highly cost-effective for medium to high-volume production.

Integrating Heat Treatment

The brazing cycle can be designed to include other heat-treatment processes. For example, a part can be brazed and simultaneously hardened, annealed, or stress-relieved in a single furnace run, saving significant time, handling, and cost.

Understanding the Trade-offs

While powerful, furnace brazing is not a universal solution. It is essential to understand its specific requirements and limitations.

Higher Initial Capital Cost

Industrial furnaces, particularly vacuum furnaces, represent a significant capital investment compared to standard welding equipment. This cost is typically justified for high-volume or high-value components.

Joint Design and Tolerances

Effective brazing relies on capillary action to draw the filler metal into the joint. This requires part designs with consistent, tight clearances (typically a few thousandths of an inch). It is less forgiving of poor fit-up and large gaps than many welding processes.

Cycle Times

While a single furnace run can process many parts, the overall cycle of heating, soaking, and cooling can take several hours. For one-off repairs or very small batches, manual welding is often faster.

When to Choose Furnace Brazing

Use this guide to determine if furnace brazing is the right choice for your application.

- If your primary focus is complex, high-precision assemblies: Furnace brazing is unmatched for creating multiple, clean joints simultaneously with minimal distortion.

- If your primary focus is joining dissimilar materials: This process is ideal for creating strong bonds between materials that cannot be welded together, such as steel and copper or metals and ceramics.

- If your primary focus is high-volume, cost-effective production: The high degree of automation, reproducibility, and ability to combine heat treatment cycles make it exceptionally efficient at scale.

Ultimately, choosing furnace brazing is a strategic decision to prioritize joint quality, design freedom, and manufacturing consistency.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Controlled Thermal Environment | Uniform heating and cooling minimizes distortion | High-precision components with tight tolerances |

| Clean, Flux-Free Joints | No corrosive fluxes or post-braze cleaning needed | Applications requiring high-purity, contamination-free joints |

| Joining Dissimilar Materials | Bonds metals and non-metals like steel to copper or ceramics | Complex assemblies with unweldable material combinations |

| Scalability and Automation | Consistent, reproducible results for high-volume production | Medium to high-volume manufacturing with quality control |

Ready to enhance your manufacturing process with furnace brazing? KINTEK specializes in advanced lab equipment and consumables, providing the precise thermal solutions your laboratory needs for high-integrity metal joining. Whether you're working with complex assemblies, dissimilar materials, or high-volume production, our expertise ensures superior joint quality and design freedom. Contact us today to discuss how our furnace brazing solutions can transform your metal joining capabilities!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy