For rosin press heat plates, 6061 aluminum is the superior and industry-standard material. While stainless steel may seem like a more premium option, its poor thermal conductivity makes it less effective for this specific application. Aluminum's ability to heat up quickly, distribute temperature evenly, and recover rapidly between presses is critical for achieving high-quality, consistent results.

The core decision between aluminum and stainless steel is a trade-off between heat transfer speed and heat retention. For the dynamic process of rosin pressing, aluminum's rapid and precise heat transfer is far more valuable than steel's slow-to-heat, slow-to-cool nature.

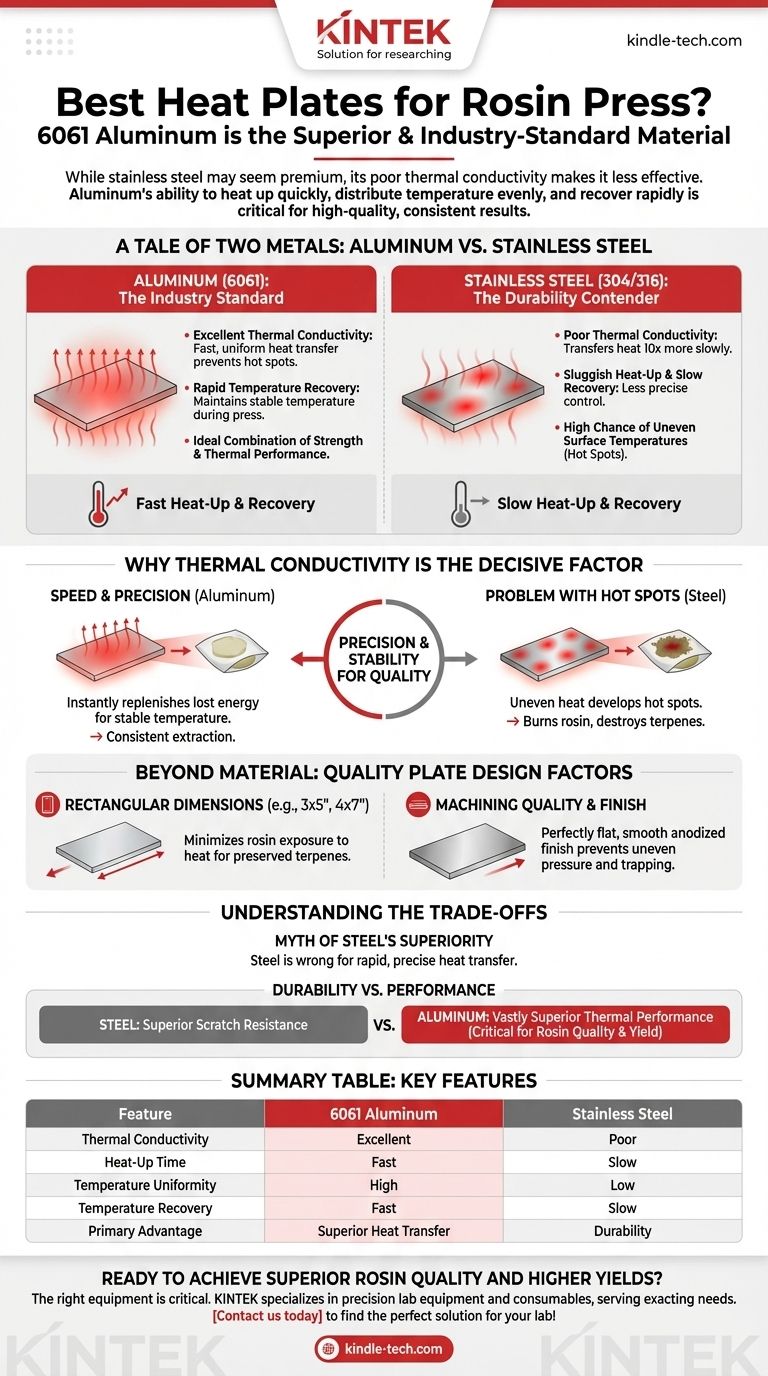

A Tale of Two Metals: Aluminum vs. Stainless Steel

Understanding the fundamental properties of each material is key to appreciating why one is better suited for pressing rosin than the other.

Aluminum (6061): The Industry Standard

The vast majority of high-quality rosin presses use 6061-T6 aluminum. This specific alloy offers an ideal combination of strength and thermal performance.

Its primary advantage is excellent thermal conductivity. This means heat from the internal cartridges transfers to the plate surface quickly and, most importantly, uniformly. This prevents "hot spots" that can scorch valuable terpenes and degrade your final product.

This rapid heat transfer also allows the plates to recover temperature quickly after coming into contact with a cool rosin bag, ensuring the temperature you set is the temperature you actually press at.

Stainless Steel (304/316): The Durability Contender

Stainless steel is known for its exceptional durability, hardness, and corrosion resistance. It is an excellent material for many applications, but it has one major drawback for a rosin press: poor thermal conductivity.

Compared to 6061 aluminum, stainless steel transfers heat roughly 10 times more slowly. This sluggishness leads to longer heat-up times and a much higher chance of uneven surface temperatures.

While steel retains heat longer, this is a disadvantage in rosin pressing. It makes the plates less responsive to the controller, meaning you have less precise control over the entire process.

Why Thermal Conductivity is the Decisive Factor

In a process as sensitive as pressing rosin, precise and stable temperature control is not a luxury—it is a requirement for quality.

The Need for Speed and Precision

The moment your plates touch the rosin bag, they begin transferring heat energy. A material with high thermal conductivity, like aluminum, can instantly replenish this lost energy, maintaining a stable pressing temperature.

Steel's slow transfer rate means the plate surface temperature can drop significantly during a press, leading to inconsistent extraction and lower yields.

The Problem with "Hot Spots"

Because steel heats unevenly, you can develop areas on the plate that are significantly hotter or cooler than your target temperature.

These hot spots can burn the rosin, destroying its flavor and aroma profile. Consistent, edge-to-edge temperature, easily achieved with aluminum, is essential for preserving delicate terpenes.

Beyond Material: What Else Defines a Quality Plate?

While 6061 aluminum is the correct material choice, other design factors play a critical role in performance.

Plate Dimensions and Aspect Ratio

Modern press plates favor rectangular shapes (e.g., 3x5", 4x7") over squares. This is a functional design choice.

A rectangular shape minimizes the distance the rosin has to travel to escape the heated plates. A shorter path means less time exposed to heat, which better preserves the terpene profile of the extract.

Machining Quality and Finish

High-quality plates should be machined to be perfectly flat. Any warping or imperfections will result in uneven pressure distribution, creating channels where rosin can get trapped and over-cooked.

A smooth, anodized finish not only adds durability but also makes it easier to collect your rosin after the press.

Understanding the Trade-offs

It's easy to assume that a heavier, harder material like stainless steel is inherently "better," but that's a misunderstanding of the physics involved.

The Myth of Steel's "Superiority"

We associate stainless steel with premium kitchen appliances and surgical tools, leading to the assumption that it must be the best option. However, in applications where rapid and precise heat transfer is the primary goal, steel is simply the wrong tool for the job.

Durability vs. Performance

The core trade-off is simple: Steel offers superior scratch resistance at the cost of thermal performance. Aluminum offers vastly superior thermal performance while still being more than durable enough to handle the immense pressures of rosin extraction.

For rosin pressing, thermal performance is directly linked to rosin quality and yield, making it the far more important attribute.

Making the Right Choice for Your Goal

When selecting plates or a full press, use this knowledge to guide your decision.

- If your primary focus is maximizing quality and yield: Unquestionably choose plates made from 6061 aluminum with a rectangular aspect ratio.

- If you are building a budget DIY press: 6061 aluminum remains the most cost-effective and best-performing choice, ensuring your efforts produce high-quality results.

- If you are evaluating a pre-built press: Make 6061 aluminum plates a non-negotiable feature and treat any press using steel plates with skepticism, as it suggests a misunderstanding of the core process.

Ultimately, choosing the right material is about understanding the science of extraction to get the most out of your starting material.

Summary Table:

| Feature | 6061 Aluminum | Stainless Steel |

|---|---|---|

| Thermal Conductivity | Excellent (Industry Standard) | Poor (10x Slower) |

| Heat-Up Time | Fast | Slow |

| Temperature Uniformity | High (Prevents Hot Spots) | Low (Risk of Hot Spots) |

| Temperature Recovery | Fast | Slow |

| Primary Advantage | Superior Heat Transfer for Quality/Yield | Scratch Resistance/Durability |

Ready to achieve superior rosin quality and higher yields? The right equipment is critical. KINTEK specializes in precision lab equipment and consumables, serving the exacting needs of laboratory professionals and extraction experts. Our expertise ensures you get the performance and reliability your process demands. Contact us today to find the perfect solution for your lab!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- Why is a high-tonnage laboratory hydraulic press required for hot-pressing TlBr? Optimize Your Radiation Detectors

- How does a laboratory hydraulic hot press ensure the quality of PHBV/natural fiber composites? Expert Guide

- How does the lamination process work? A Guide to Creating Superior Composite Materials

- What is the temperature and pressure of hot pressing? Tailoring Parameters for Your Material

- Why is hot press molding preferred over traditional solution casting? Expert Comparison for Polymer Electrolytes

- What is the difference between heat press and sublimation? A Tool vs. a Process Explained

- What is the core function of a laboratory heated hydraulic press in CSP? Optimize Solid-State Battery Densification

- What is the function of a laboratory hot press in PEMWE assembly? Optimize MEA Integrity & Performance