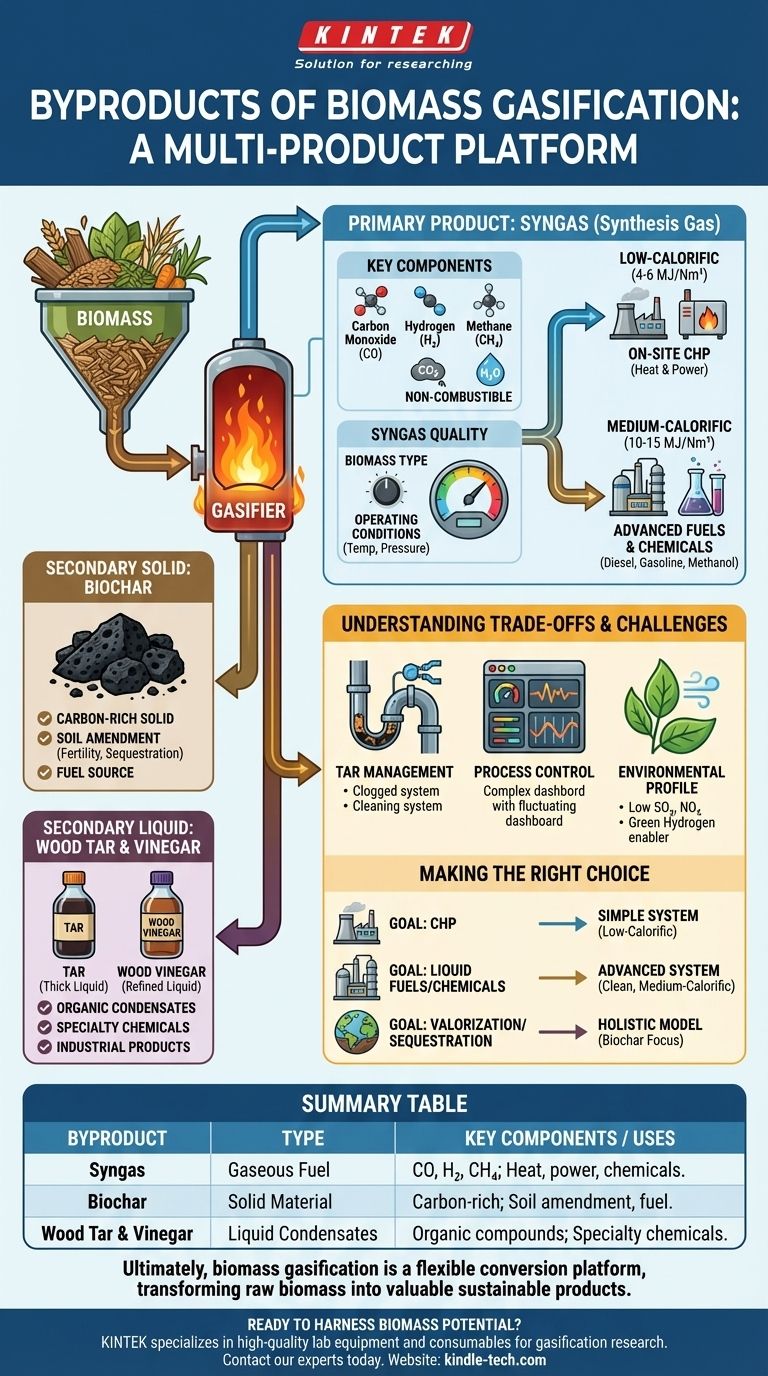

At its core, biomass gasification is a thermochemical process that converts solid biomass into a mixture of useful products. The primary output is a combustible gas mixture known as syngas, but the process also yields valuable solid and liquid byproducts, including biochar (charcoal), wood tar, and wood vinegar.

The central purpose of biomass gasification is not merely to produce a single fuel, but to unlock the full potential of biomass by transforming it into a versatile portfolio of energy carriers and chemical feedstocks.

The Primary Product: Synthesis Gas (Syngas)

The main goal of gasification is to create synthesis gas, or syngas, which is a mixture of different gases. The specific composition determines its quality and how it can be used.

Key Components of Syngas

The value of syngas comes from its combustible components, primarily carbon monoxide (CO), hydrogen (H₂), and methane (CH₄). The process also generates non-combustible gases like carbon dioxide (CO₂) and water vapor (H₂O).

What Determines Syngas Quality?

The final ratio of these gases is not accidental. It is heavily influenced by the specific type of biomass used and the precise operating conditions of the gasifier, such as temperature and pressure.

Controlling these factors allows operators to tailor the output for specific applications, directly impacting the gas's energy content, or calorific value.

Applications Based on Calorific Value

Syngas is not a one-size-fits-all fuel. Its applications are segmented by its quality.

Low-calorific syngas (4-6 MJ/Nm³) is perfectly suitable for direct combustion. It is most commonly used on-site for combined heat and power (CHP) generation.

Medium-calorific syngas (10-15 MJ/Nm³) is a higher-value product. This cleaner, more energy-dense gas can serve as a feedstock for creating advanced liquid fuels like synthetic diesel and gasoline, or valuable green chemicals such as methanol and acetic acid.

Secondary Byproducts: The Solid and Liquid Outputs

Beyond syngas, the gasification process yields other materials that have significant value. These are not waste products but rather co-products of the conversion.

Biochar (Biomass Charcoal)

This solid, carbon-rich material is what remains of the biomass after the volatile gases have been released. Biochar can be used as a fuel itself or, more importantly, as a powerful soil amendment that improves fertility and sequesters carbon in the ground.

Tar and Wood Vinegar

During the process, heavy organic compounds can be condensed into a thick, dark liquid known as wood tar. A more refined liquid fraction, wood vinegar (pyroligneous acid), is also produced. Both can be further processed into specialty chemicals and other industrial products.

Understanding the Trade-offs

While powerful, biomass gasification is a complex process with inherent challenges that must be managed for successful operation.

The Challenge of Tar

Tar is one of the most significant operational hurdles. If not properly managed, these sticky compounds can condense and clog downstream equipment, leading to system shutdowns. Advanced gasifier designs and gas cleanup systems are critical for handling tar effectively.

Process Complexity and Control

Achieving a consistent, high-quality output of syngas and byproducts requires precise control over the gasification process. Variations in feedstock moisture, particle size, and reactor temperature can dramatically alter the results, demanding sophisticated monitoring and management.

Environmental Profile

When managed correctly, gasification offers a strong environmental advantage. The resulting fuel is very low in sulfur oxides (SOx) and nitrogen oxides (NOx), making it a clean-burning alternative to fossil fuels. It is a key enabling technology for producing green hydrogen, a climate-neutral energy carrier.

Making the Right Choice for Your Goal

The optimal approach to gasification depends entirely on your end goal.

- If your primary focus is on-site heat and electricity: A simpler system designed to produce low-calorific syngas for direct use in a CHP unit is the most straightforward and cost-effective path.

- If your primary focus is producing high-value liquid fuels or chemicals: You will need a more advanced gasification and gas cleanup system capable of generating clean, medium-calorific syngas suitable for catalytic conversion.

- If your primary focus is waste valorization and carbon sequestration: Your model should account for the entire value chain, treating biochar not as waste but as a key co-product for soil amendment and carbon storage.

Ultimately, biomass gasification is best understood as a flexible conversion platform that transforms raw biomass into a suite of valuable and sustainable products.

Summary Table:

| Byproduct | Type | Key Components / Uses |

|---|---|---|

| Syngas | Gaseous Fuel | CO, H₂, CH₄; used for heat, power, or chemical production. |

| Biochar | Solid Material | Carbon-rich; used as a soil amendment or fuel. |

| Wood Tar & Vinegar | Liquid Condensates | Organic compounds; used for specialty chemicals. |

Ready to harness the full potential of biomass conversion for your laboratory or pilot plant? KINTEK specializes in high-quality lab equipment and consumables for gasification research and analysis. Whether you are developing new catalysts, analyzing syngas composition, or characterizing biochar, our solutions provide the precision and reliability you need. Contact our experts today to discuss how we can support your sustainable energy projects!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Air Valve Applications

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- High Purity Zinc Foil for Battery Lab Applications

- Assemble Square Lab Press Mold for Laboratory Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

People Also Ask

- What are the advantages of pyrolysis system? Turn Waste into Renewable Energy & Revenue

- What is the process of pyrolysis for the treatment of food waste? Convert Waste into Bio-Oil, Biochar & Syngas

- What is bio-oil production from biomass by using pyrolysis method? Turn Waste into Liquid Fuel

- What is the advantage of pyrolysis? Transforming Waste into High-Value Biofuels and Biochar

- Which catalyst used in biomass pyrolysis for production of bio-oil? Select the Right Catalyst for Your Bio-Oil

- What is the purpose of pyrolysis? Transforming Waste into Valuable Energy and Materials

- Which ores undergo calcination? A Guide to Carbonate and Hydrated Ore Processing

- What are the different types of calcination? Choosing the Right Method for Your Material