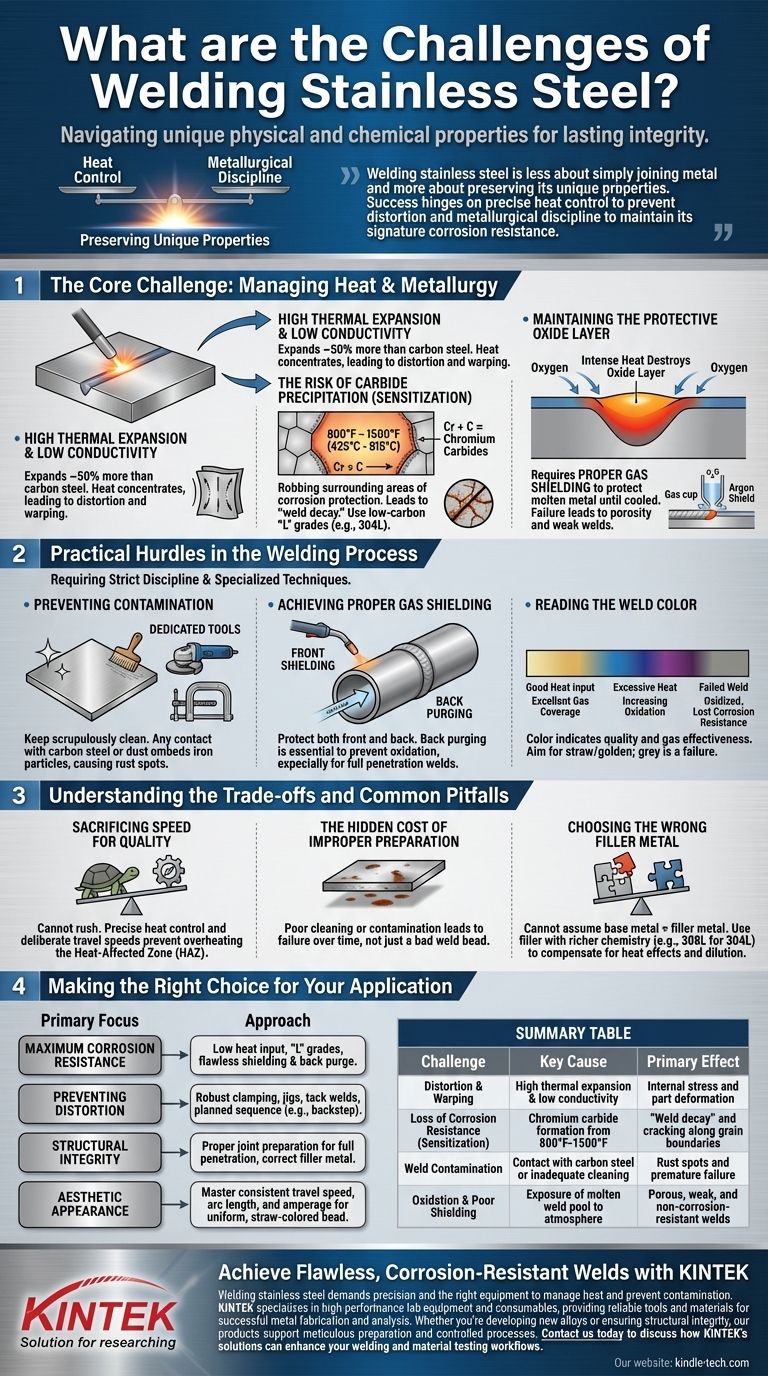

In short, the primary challenges of welding stainless steel stem from its unique physical and chemical properties. Unlike carbon steel, it has poor thermal conductivity and high thermal expansion, which leads to warping. It is also highly susceptible to losing its corrosion resistance if overheated and is easily contaminated by less noble metals.

Welding stainless steel is less about simply joining metal and more about preserving its unique properties. Success hinges on precise heat control to prevent distortion and metallurgical discipline to maintain its signature corrosion resistance.

The Core Challenge: Managing Heat and Metallurgy

Stainless steel's greatest strengths—its hardness and resistance to corrosion—are also the source of its welding challenges. The welding process subjects the metal to extreme conditions that can compromise these very properties.

High Thermal Expansion & Low Conductivity

Stainless steel expands about 50% more than carbon steel when heated. Simultaneously, it is a poor conductor of heat, meaning the heat from the welding arc doesn't dissipate quickly and remains concentrated in a small area.

This combination is the primary cause of distortion and warping. The localized area gets extremely hot and expands rapidly while the surrounding metal stays cool, creating immense internal stress that pulls and twists the material as it cools.

The Risk of Carbide Precipitation (Sensitization)

The corrosion resistance of stainless steel comes from chromium, which forms a passive, protective layer of chromium oxide on the surface.

If common austenitic stainless steels (like the 304 grade) are held in a temperature range of approximately 800°F to 1500°F (425°C to 815°C) for too long, the chromium can bond with carbon in the steel. This forms chromium carbides along the grain boundaries.

This process, called sensitization, robs the surrounding areas of the chromium needed for corrosion protection. The weld may look perfect, but it will be highly vulnerable to rust and cracking along these depleted boundaries, a failure known as "weld decay." Using low-carbon "L" grades, such as 304L, helps mitigate this risk.

Maintaining the Protective Oxide Layer

The intense heat of the welding arc destroys the passive chromium oxide layer. If the molten weld pool is exposed to oxygen in the atmosphere, it will oxidize rapidly, resulting in a porous, weak, and non-corrosion-resistant weld.

This makes proper gas shielding absolutely critical to protect the molten metal from the atmosphere until it has cooled.

Practical Hurdles in the Welding Process

Beyond the metallurgical theory, welders face several practical challenges that require strict discipline and specialized techniques.

Preventing Contamination

Stainless steel must be kept scrupulously clean. Any contact with carbon steel tools, grinding wheels, or even airborne dust can embed iron particles into the surface.

These free iron particles are not protected by the chromium oxide layer and will rust, creating small spots of corrosion that can compromise the entire workpiece. For this reason, all tools—brushes, clamps, and grinders—must be dedicated exclusively to stainless steel.

Achieving Proper Gas Shielding

To prevent oxidation, both the front and back of the weld must be protected from the atmosphere. While the welding torch provides shielding to the front, the back side of the weld root is vulnerable.

This requires back purging, the process of filling the inside of a pipe or the back of a seam with an inert gas (typically Argon). Failing to back-purge a stainless steel weld, especially on a full penetration weld, guarantees oxidation and will lead to premature failure.

Reading the Weld Color

The final color of a stainless steel weld is a direct indicator of the quality of the weld and the effectiveness of the gas shielding.

A light straw or golden color indicates proper heat input and excellent gas coverage. As the color shifts to blue, purple, and finally a dull grey, it signifies excessive heat and increasing levels of oxidation. A grey, crusty weld is oxidized, has lost its corrosion resistance, and should be considered a failed weld.

Understanding the Trade-offs and Common Pitfalls

Successfully welding stainless steel often involves balancing competing priorities and avoiding common mistakes that can lead to hidden failures.

Sacrificing Speed for Quality

The need for precise heat control means you cannot rush a stainless steel weld. The mantra is to use enough heat for good fusion but to move quickly enough to avoid overheating the Heat-Affected Zone (HAZ). This delicate balance often requires lower amperage settings and more deliberate travel speeds compared to carbon steel.

The Hidden Cost of Improper Preparation

A weld might look structurally sound on the surface, but if the material wasn't properly cleaned or was contaminated with carbon steel, it will fail over time. The rust spots that appear weeks later are a direct result of poor preparation, not a faulty weld bead.

Choosing the Wrong Filler Metal

You cannot assume a 304 filler rod is always correct for a 304 base metal. To compensate for heat effects and dilution during welding, it's common to use a filler metal with slightly richer chemistry, like 308L, to weld 304L. Using the wrong filler can result in a weld that is prone to cracking or lacks the required corrosion resistance.

Making the Right Choice for Your Application

Your welding approach should be tailored to the primary requirements of the finished product.

- If your primary focus is maximum corrosion resistance: Prioritize low heat input, use "L" grade materials, and ensure flawless gas shielding with a thorough back purge.

- If your primary focus is preventing distortion: Use robust clamping and jigs, strategically place tack welds, and use a planned sequence (like backstep welding) to distribute heat stress.

- If your primary focus is structural integrity: Ensure proper joint preparation for full penetration and select the correct filler metal for the specific base materials being joined.

- If your primary focus is aesthetic appearance: Master consistent travel speed, arc length, and amperage to produce a uniform, straw-colored weld bead.

Mastering these principles transforms stainless steel welding from a challenge into a predictable and repeatable craft.

Summary Table:

| Challenge | Key Cause | Primary Effect |

|---|---|---|

| Distortion & Warping | High thermal expansion & low conductivity | Internal stress and part deformation |

| Loss of Corrosion Resistance (Sensitization) | Chromium carbide formation from 800°F-1500°F | 'Weld decay' and cracking along grain boundaries |

| Weld Contamination | Contact with carbon steel or inadequate cleaning | Rust spots and premature failure |

| Oxidation & Poor Shielding | Exposure of molten weld pool to atmosphere | Porous, weak, and non-corrosion-resistant welds |

Achieve Flawless, Corrosion-Resistant Welds with KINTEK

Welding stainless steel demands precision and the right equipment to manage heat and prevent contamination. KINTEK specializes in high-performance lab equipment and consumables, providing the reliable tools and materials your laboratory needs for successful metal fabrication and analysis.

Whether you're developing new alloys or ensuring the structural integrity of components, our products support the meticulous preparation and controlled processes essential for welding stainless steel.

Contact us today to discuss how KINTEK's solutions can enhance your welding and material testing workflows.

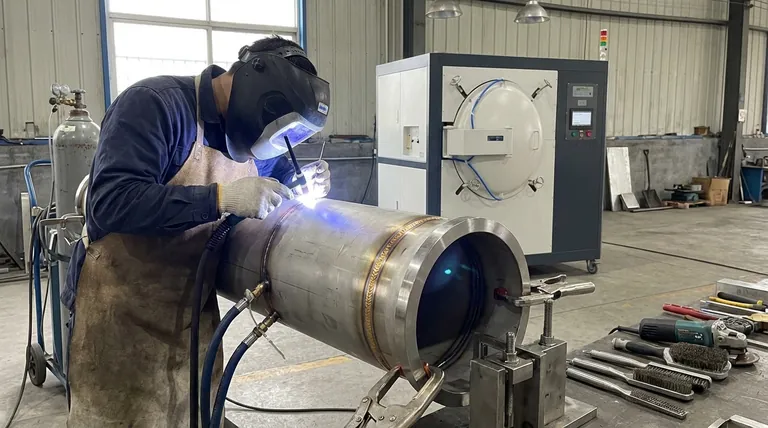

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

People Also Ask

- Why is biomass energy not efficient? The Hidden Costs of Low-Energy Fuel

- What temperature does THC sublimate at? Discover the Optimal Vaporization Range

- What is the importance of sintering? Unlock Strength, Density, and Complex Part Production

- What is the most commonly used in semiconductors? Discover Why Silicon Dominates Modern Electronics

- Can biomass be used for transportation? A Guide to Biofuels, Processes, and Trade-offs

- What are the defects in sintered parts? Avoid Warping, Cracking, and Porosity Issues

- What roles do bed materials play in biomass gasification? Optimizing Heat Transfer and Chemical Stability

- What is the process of reactive sputtering? Create High-Performance Compound Films Efficiently