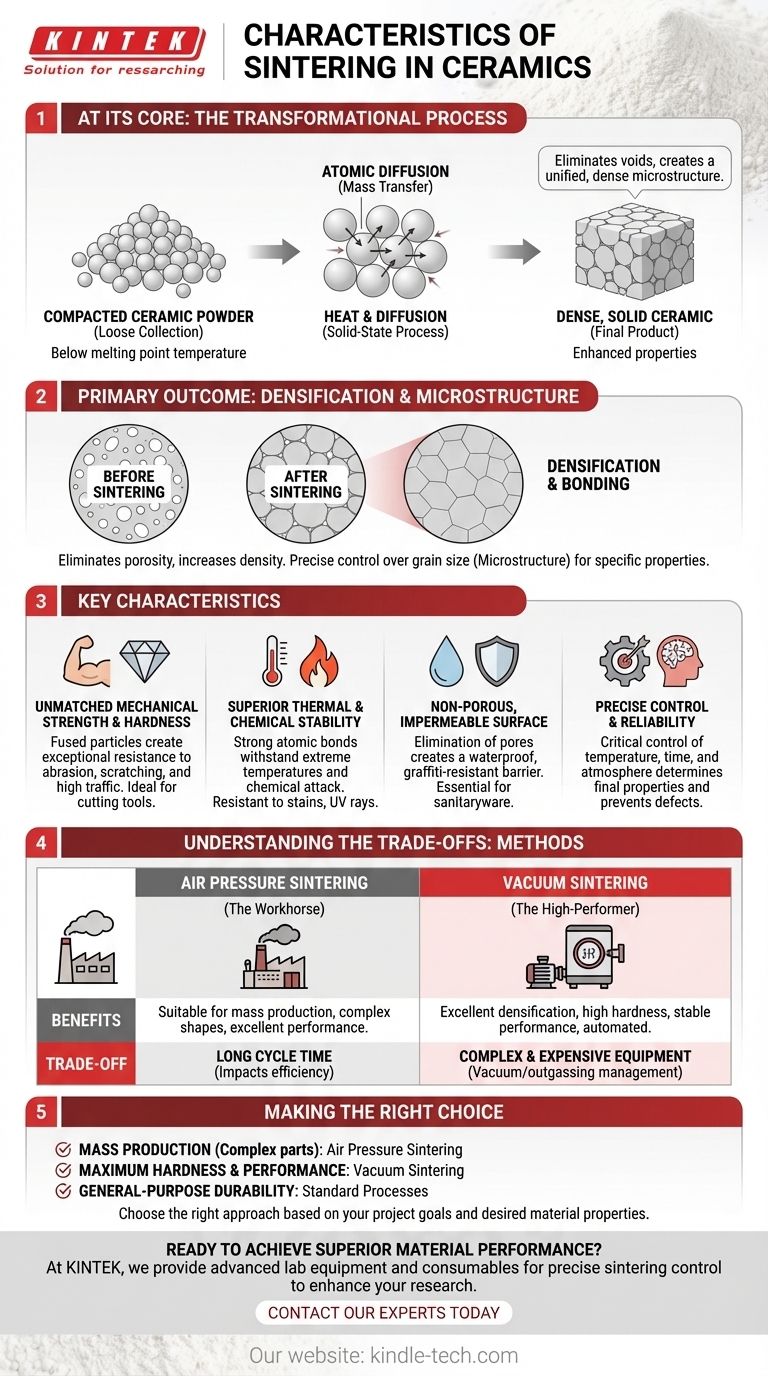

At its core, sintering is a high-temperature process that transforms a loose collection of ceramic powder into a dense, solid, and highly durable material. This transformation is not melting; it is a solid-state process of atomic diffusion that fundamentally enhances the ceramic's mechanical strength, hardness, and resistance to environmental factors. The final product is characterized by its exceptional durability, thermal stability, and impermeability.

Sintering is the essential manufacturing step where a ceramic component gains its engineered properties. It works by eliminating the voids between powder particles, creating a unified, dense microstructure that is responsible for the material's final strength and resilience.

The Fundamental Goal: From Powder to Solid

Sintering is the most critical stage in the production of advanced ceramics. It is the bridge between a raw, powdered material and a finished, high-performance component.

What Happens During Sintering?

The process involves heating the compacted ceramic powder to a temperature below its melting point. This thermal energy causes the atoms on the surfaces of the particles to diffuse, or move, across the boundaries between them.

This mass transfer effectively closes the pores and voids that exist between the individual powder grains, welding them together into a coherent and dense polycrystalline structure.

The Primary Outcome: Densification

The main objective of sintering is densification. By eliminating porosity, the process dramatically increases the material's density, which is directly linked to its mechanical properties.

A well-sintered ceramic has minimal internal voids, preventing cracks from initiating and propagating. This results in superior hardness and strength.

Developing the Microstructure

Sintering creates a specific microstructure—the arrangement and size of the crystalline grains. The parameters of the sintering process, such as temperature, time, and atmosphere, are carefully controlled to produce the exact microstructure required for a specific application.

Key Characteristics of Sintered Ceramics

The densification and bonding achieved during sintering impart a range of powerful characteristics to the final ceramic part.

Unmatched Mechanical Strength and Hardness

Because the particles are fused into a dense mass, sintered ceramics are exceptionally hard and resistant to scratching and high-traffic abrasion. This inherent strength makes them ideal for applications like cutting tools and durable tiles.

Superior Thermal and Chemical Stability

The strong atomic bonds created during sintering result in excellent thermal stability, allowing the material to withstand extreme temperatures. Sintered ceramics are also highly resistant to chemical attack, stains, water, and damage from UV rays.

Creation of a Non-Porous, Impermeable Surface

The elimination of pores makes the surface of a sintered ceramic waterproof and resistant to graffiti. This impermeability is a key feature for products like sanitaryware and exterior cladding, which must resist moisture and environmental contaminants.

Understanding the Trade-offs: Sintering Methods

Not all sintering is the same. The method chosen depends on the desired properties, production volume, and complexity of the part, each with its own set of trade-offs.

Air Pressure Sintering (The Workhorse)

This common method is suitable for mass production and can produce parts with complex shapes and excellent performance. However, its primary trade-off is a long cycle time, which can impact production efficiency.

Vacuum Sintering (The High-Performer)

Sintering in a vacuum environment produces components with excellent densification, high hardness, and very stable performance. This method is highly automated and flexible but requires a more complex and expensive equipment setup to manage the vacuum and outgassing from materials.

The Critical Role of Control

Regardless of the method, success hinges on precise control. Process parameters are monitored to minimize human error and achieve the target density, porosity, and microstructure. Any deviation can result in a component that fails to meet performance specifications.

Making the Right Choice for Your Application

The characteristics of the final ceramic are a direct result of the sintering process used to create it. Choosing the right approach is therefore critical to meeting the goals of your project.

- If your primary focus is mass production of complex parts: Air pressure sintering is a proven method, provided you can accommodate its longer processing cycles.

- If your primary focus is maximum hardness and material performance: A more advanced technique like vacuum sintering is necessary to achieve the highest levels of densification and stability.

- If your primary focus is general-purpose durability: Even standard sintering processes for items like tiles or sanitaryware provide the fundamental benefits of hardness and impermeability needed for high-traffic and wet environments.

Ultimately, sintering is the deliberate, controlled process that unlocks the inherent potential of ceramic materials, transforming them into components engineered for performance.

Summary Table:

| Characteristic | Description |

|---|---|

| Mechanical Strength | Particles fuse into a dense mass, providing exceptional hardness and resistance to abrasion. |

| Thermal Stability | Strong atomic bonds allow the material to withstand extreme temperatures. |

| Chemical Resistance | Highly resistant to chemical attack, stains, and UV damage. |

| Impermeability | Elimination of pores creates a waterproof, graffiti-resistant surface. |

Ready to achieve superior material performance for your lab? The sintering process is critical to developing ceramics with unmatched strength and durability. At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for precise sintering control. Whether you're working on cutting tools, high-performance components, or durable materials, our solutions help you achieve the perfect densification and microstructure. Contact our experts today to discuss how we can support your laboratory's sintering needs and enhance your research and production outcomes.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What is muffle furnace principle and procedure? Master Safe, Contaminant-Free High-Temperature Processing

- How long should a furnace take to raise the temperature? Key Factors for Optimal Heating Speed

- At what temperature is it safe to open a muffle furnace? A Guide to Preventing Injury and Equipment Damage

- How are samples typically prepared and measured using the diffuse reflection method? Optimize Your Lab's IR Spectroscopy

- What is the alternative to a laboratory oven? Find the Right Heating Tool for Your Lab