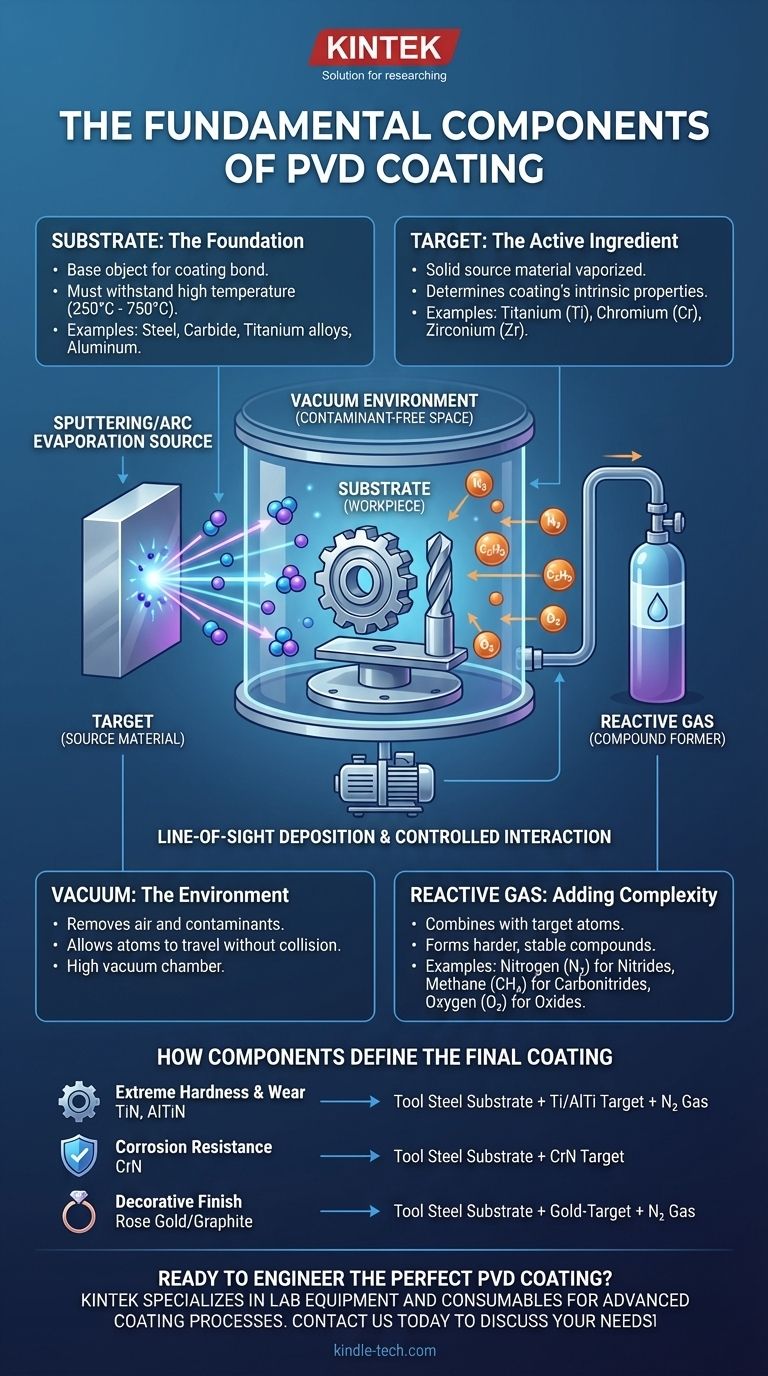

At its core, a PVD coating process consists of four fundamental components. These are the substrate (the object being coated), the target (the solid source material for the coating), the vacuum environment where the process occurs, and often, a reactive gas that combines with the target material to form the final coating compound. Understanding how these elements interact is the key to mastering PVD technology.

Physical Vapor Deposition (PVD) is not a single material, but a family of processes. Its "components" refer to the inputs of a system: the base part, the coating source, and the controlled environment that work together to deposit an engineered, high-performance thin film.

The Foundation: The Substrate

The substrate is simply the workpiece, part, or object that you intend to coat. The success of the PVD process is highly dependent on the choice and preparation of this foundational component.

What the Substrate Does

The substrate provides the physical base onto which the coating atoms will bond. Its surface condition, cleanliness, and material properties directly influence the adhesion and final performance of the PVD film.

Suitable Substrate Materials

A wide range of materials can be coated effectively. This includes nearly all steel families (especially high-speed and stainless steels), hard metals (carbides), and non-ferrous metals like titanium, aluminum, and copper alloys.

Critical Material Limitations

Some materials are unsuitable for PVD. Materials that "outgas" (release trapped gases) in a vacuum, such as galvanized materials or un-plated brass, will contaminate the chamber and prevent a quality coating from forming. The substrate must also withstand the process temperature, which can range from 250°C to 750°C.

The Active Ingredient: The Target Material

The target is the solid, pure source material that is vaporized to become the coating. The choice of target is the primary factor in determining the coating's intrinsic properties.

What the Target Is

This is typically a block or ingot of a specific metal or ceramic. Common target materials include Titanium (Ti), Chromium (Cr), Zirconium (Zr), Aluminum (Al), and Tungsten (W).

How the Target Becomes a Coating

The solid target material is converted into a vapor through a high-energy physical process inside the vacuum chamber. The two most common methods are:

- Sputtering: The target is bombarded with energetic ions (often Argon), which dislodge or "sputter" atoms from its surface.

- Cathodic Arc Evaporation: A high-current electric arc moves across the target's surface, vaporizing the material at the arc point.

These vaporized atoms then travel through the vacuum and condense onto the substrate, building the coating one atom at a time.

The Environment: Vacuum and Process Gases

The environment inside the PVD chamber is not empty; it is a highly controlled space that is just as critical as the physical materials.

The Essential Role of the Vacuum

PVD is performed under a high vacuum for two main reasons. First, it removes air and other contaminants that would otherwise react with and spoil the coating. Second, it allows the vaporized coating atoms to travel from the target to the substrate with few or no collisions.

Adding Complexity with Reactive Gases

To create harder and more stable compound coatings, a reactive gas is often introduced into the chamber. This gas combines with the metal atoms from the target as they deposit on the substrate.

- Nitrogen (N₂) is used to form hard nitride coatings (e.g., TiN, CrN).

- Acetylene (C₂H₂) or Methane (CH₄) are used to form carbonitride (e.g., TiCN) or diamond-like carbon (DLC) coatings.

- Oxygen (O₂) is used to form oxide coatings (e.g., Al₂O₃).

Understanding the Trade-offs

The physical nature of these components introduces specific limitations that must be managed for a successful outcome.

Line-of-Sight Deposition

The vaporized atoms from the target travel in a straight line. This means any surface not in the direct "line-of-sight" of the target will not be coated. To achieve uniform coverage on complex shapes, parts must be carefully fixtured and rotated during the process.

Substrate Temperature Sensitivity

The high temperatures required for good adhesion can be a limitation. This heat can alter the properties (e.g., temper) of certain heat-sensitive steels or other alloys, which must be considered during material selection.

Material Compatibility

Not every target material can be deposited on every substrate with equal success. The chemical and physical compatibility between the coating and the base material is critical for achieving the strong atomic bond that gives PVD its durability.

How the Components Define the Final Coating

The specific combination of substrate, target, and reactive gas is chosen to achieve a specific engineering goal.

- If your primary focus is extreme hardness and wear resistance: You would likely combine a tool steel substrate with a Titanium or Aluminum-Titanium target and Nitrogen gas to create a TiN or AlTiN coating.

- If your primary focus is corrosion resistance: You would pair a stainless steel substrate with a Chromium target and Nitrogen gas to form a dense, non-reactive Chromium Nitride (CrN) film.

- If your primary focus is a specific decorative finish: You might coat a polished substrate with a Zirconium target and a precise blend of Nitrogen and Carbon-based gases to achieve a specific color like rose gold or graphite.

Ultimately, mastering PVD coating is about understanding how to select and control these fundamental components to build a thin film with precisely the properties you require.

Summary Table:

| Component | Role | Key Examples |

|---|---|---|

| Substrate | The base object being coated | Steel, Carbide, Titanium alloys |

| Target | The solid source material vaporized | Titanium (Ti), Chromium (Cr), Zirconium (Zr) |

| Vacuum | Creates a contaminant-free environment | High vacuum chamber |

| Reactive Gas | Combines with target to form compounds | Nitrogen (N₂), Acetylene (C₂H₂), Oxygen (O₂) |

Ready to engineer the perfect PVD coating for your application? The right combination of substrate, target, and process gas is critical for achieving superior hardness, wear resistance, or corrosion protection. KINTEK specializes in lab equipment and consumables for advanced coating processes. Our experts can help you select the ideal components for your specific needs. Contact us today to discuss how we can support your laboratory's coating challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells