To operate a muffle furnace correctly, you must establish a specific set of environmental, operational, and safety conditions. The furnace requires a clean, well-ventilated workspace free of corrosive gases, flammable materials, and strong electromagnetic fields. Operationally, the chamber must be kept clean, samples must be placed securely without touching the heating elements, and the unit must be allowed to cool before samples are removed.

The core principle is that a muffle furnace is a precision instrument, not just a simple oven. Its required conditions are not merely suggestions; they are essential rules designed to protect the user, ensure the longevity of the equipment, and guarantee the integrity of the heating process itself.

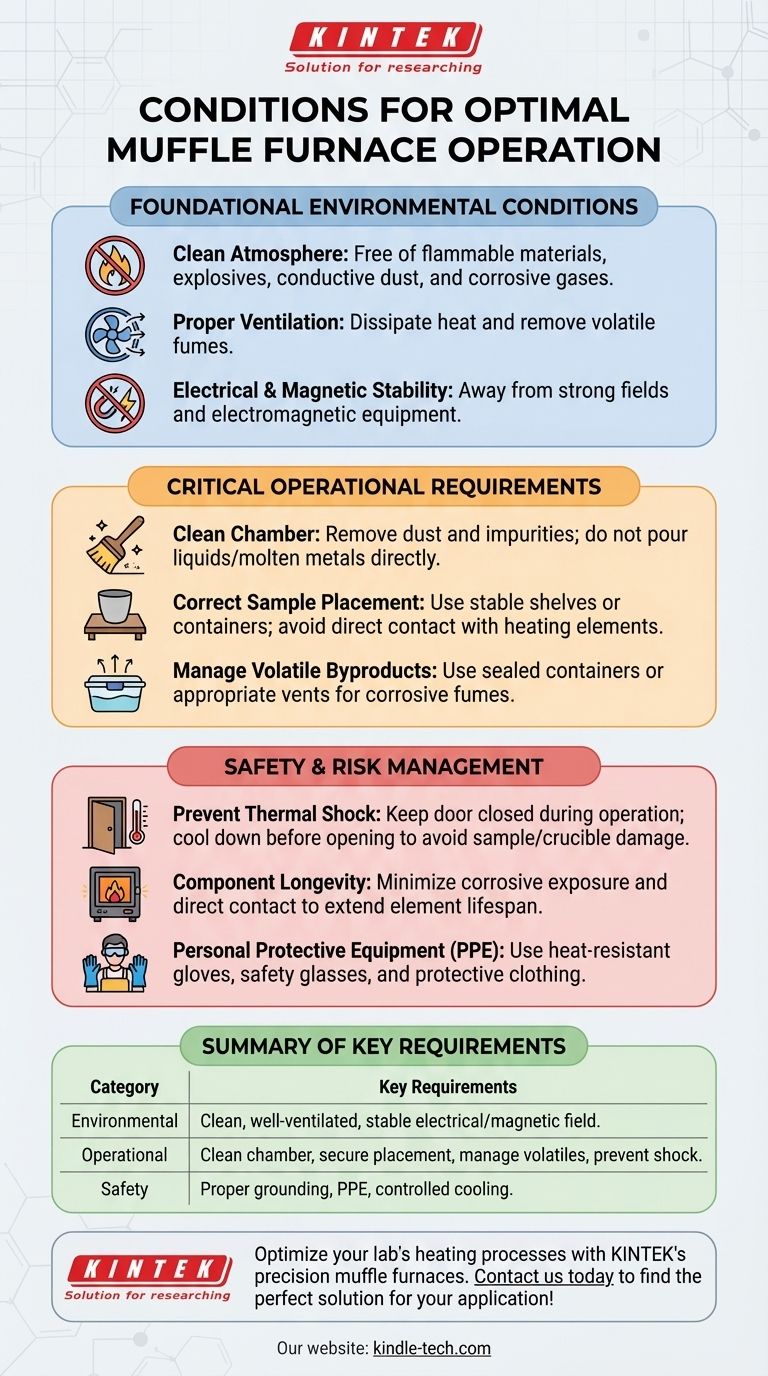

Foundational Environmental Conditions

The physical location and atmosphere where the furnace operates are the first line of defense for ensuring safety and performance.

The Importance of a Clean Atmosphere

The operating environment must be free from flammable materials, explosive substances, and conductive dust. The presence of these can create significant fire or electrical hazards.

Furthermore, the air should not contain corrosive gases. These gases can attack and degrade the internal electric heating elements, drastically reducing the furnace's lifespan and performance.

Ensuring Proper Ventilation

The room must be well-ventilated. This helps dissipate the substantial heat generated by the furnace and safely removes any volatile fumes or gases released from the materials being heated.

Electrical and Magnetic Stability

The furnace and its controller should be placed away from any strong electromagnetic equipment or strong magnetic fields. These fields can interfere with the controller's sensitive electronics, leading to inaccurate temperature readings and poor process control.

Critical Operational Requirements

How you use the furnace is as important as where you place it. Following a strict operational protocol prevents damage and ensures reliable results.

Preparing the Furnace Chamber

The furnace chamber must be kept scrupulously clean. Any dust, fibers, or other impurities can contaminate your samples or affect furnace operation.

Never pour liquids or molten metals directly into the furnace. For a new furnace or one that has been idle, run an empty heating cycle to bake out any residual moisture and impurities.

Correctly Placing Samples

Always place samples on a stable shelf or in an appropriate container. Ensure they cannot tip over during the process.

Crucially, do not place samples directly on the heating elements or the furnace floor if elements are embedded there. This poses a severe fire risk and can cause immediate damage to the elements.

Managing Volatile Byproducts

When heating materials that release volatile gases, such as grease or certain metals, these fumes can corrode the heating elements.

To prevent this, use sealed containers or ensure the furnace is equipped with appropriate vents to safely exhaust the corrosive byproducts from the chamber.

Understanding the Trade-offs and Risks

Operating a muffle furnace involves balancing temperature, time, and material properties while being aware of inherent risks.

Material-Specific Heat Treatment

Different materials require specific conditions. For example, Pyrex might be baked at 500°C for an hour, while quartz may need 1000°C for the same duration.

These are only examples; you must always refer to the specific protocol for the material you are processing to avoid damage or incomplete treatment.

The Danger of Thermal Shock

Keep the furnace door closed during operation to maintain temperature stability and prevent heat loss. Rapid temperature changes create a risk of thermal shock.

Allow the furnace to cool to a safe temperature before opening the door and removing samples. Exposing a very hot crucible or sample to cool room air can cause it to crack or shatter.

Inevitable Wear on Components

Even with perfect use, heating elements have a finite lifespan. Adhering to proper conditions—especially avoiding corrosive atmospheres and direct contact—is the best way to maximize their service life.

Final Checklist: Setup and Safety

Before turning the furnace on, run through this final checklist.

Physical and Electrical Setup

Place the furnace on a flat, stable surface. Position the controller away from the furnace body to protect it from overheating.

Ensure the furnace and controller are properly grounded and that a dedicated power switch is installed for the main power line.

Thermocouple and Controller

Insert the thermocouple correctly into the furnace, using asbestos rope to seal any gaps. When connecting the compensation wire to the controller, double-check that the positive and negative polarity is correct.

Personal Protective Equipment (PPE)

Due to the extreme temperatures, never operate the furnace without proper PPE. This includes heat-resistant gloves, safety glasses, and appropriate protective clothing. Never stand close to an operating furnace without thermal protection.

Applying This to Your Goal

Your specific objective dictates which conditions deserve the most focus.

- If your primary focus is process integrity: Prioritize a clean chamber, an initial bake-out cycle for new or unused furnaces, and managing volatile byproducts with sealed containers or venting.

- If your primary focus is equipment longevity: Pay closest attention to avoiding corrosive atmospheres, preventing direct sample contact with heating elements, and allowing for slow cooling to prevent thermal shock to the chamber lining.

- If your primary focus is user safety: Emphasize proper ventilation, correct electrical grounding, and the consistent use of personal protective equipment.

By controlling these conditions, you transform the muffle furnace from a simple heat source into a reliable and precise scientific tool.

Summary Table:

| Condition Category | Key Requirements |

|---|---|

| Environmental | Clean, well-ventilated space; free of flammable materials, corrosive gases, and strong electromagnetic fields. |

| Operational | Clean chamber; secure sample placement away from heating elements; manage volatile byproducts; prevent thermal shock. |

| Safety | Proper grounding; use of PPE (heat-resistant gloves, safety glasses); controlled cooling before opening. |

Optimize your lab's heating processes with KINTEK's precision muffle furnaces. Our equipment is designed to meet the strictest operational conditions, ensuring safety, durability, and accurate results for your laboratory needs. Contact us today to find the perfect solution for your application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why are high-precision electric furnaces required for PHBV research? Master Thermal Control for Material Stability

- What are the disadvantages of heat treatment of metals? Managing the Risks of Distortion and Brittleness

- What is the role of a muffle furnace in nitrogen-doped biochar prep? Key Benefits for Precise Atmosphere Control

- What is oven used in laboratory? Essential Thermal Processing for Drying, Sterilizing, and Curing

- What is the purpose of the 400 °C annealing for ceramic green bodies? Ensure Structural Integrity & Prevent Cracking

- What role does a high-temperature muffle furnace play in the synthesis of mesoporous silica materials? Expert Insights

- What is the primary application of high-precision furnaces in the solid-state synthesis of mixed niobates like La1-xYxNbO4?

- What is the role of high-temperature furnaces in red mud brick production? Master Slow-Burning for Superior Strength