Defects in heat-treated steel are primarily caused by the immense thermal and metallurgical stresses introduced during heating and rapid cooling. The most common defects are cracking, distortion (warping), undesirable surface changes like decarburization and scaling, and failure to achieve the target hardness or microstructure. These failures are not random but are direct consequences of improperly controlled process parameters.

Heat treatment defects are predictable outcomes of thermal stress, phase transformations, and atmospheric chemical reactions. Preventing them hinges on rigorously controlling the rate of temperature change, the furnace atmosphere, and the part's geometry from the design stage onward.

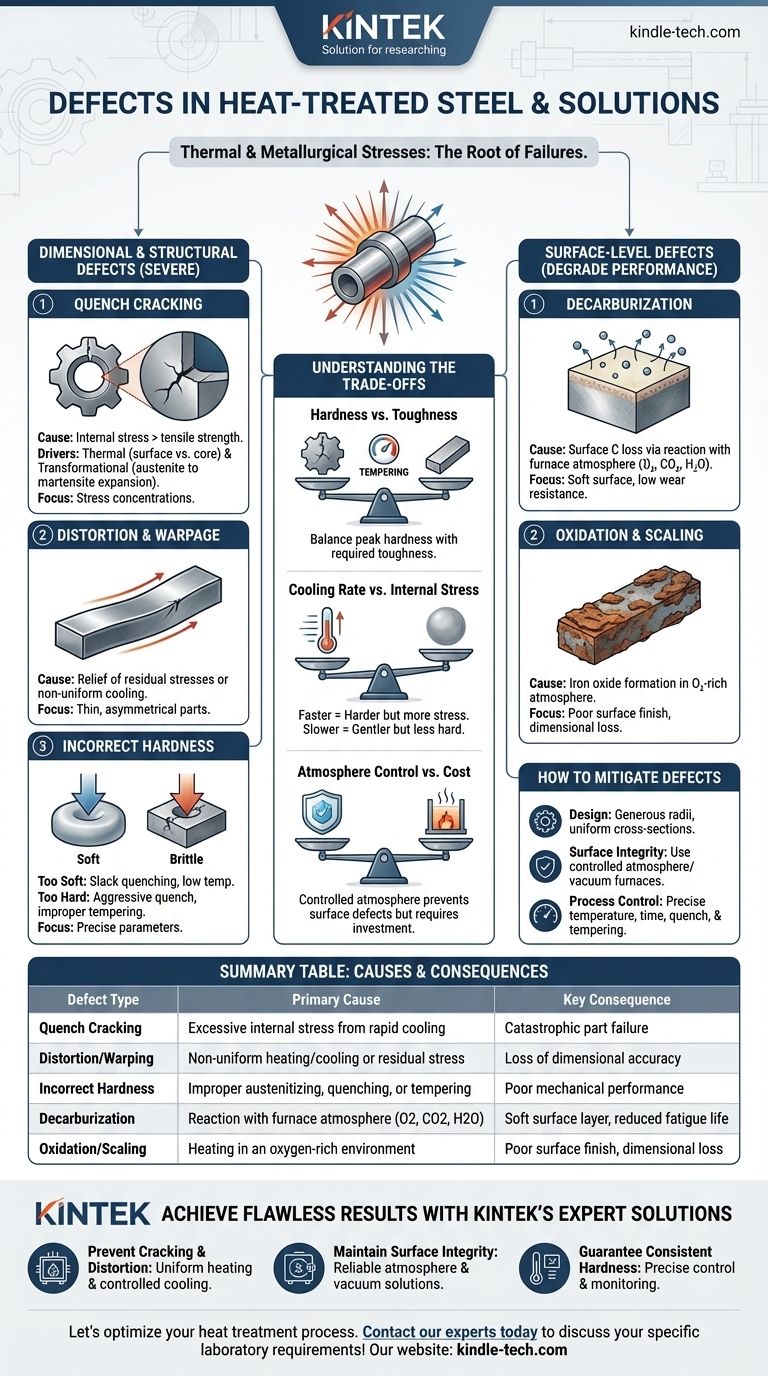

Dimensional and Structural Failures

The most severe defects compromise the mechanical integrity and dimensional accuracy of the component, often rendering it unusable.

Quench Cracking

Quench cracking is the most critical heat treatment defect. It occurs when internal stresses from quenching exceed the ultimate tensile strength of the material.

This is driven by two primary forces: thermal stress from the surface cooling much faster than the core, and transformational stress from the expansion that occurs as austenite transforms into brittle martensite.

Cracks typically originate at stress concentration points like sharp corners, keyways, or sudden changes in the part's cross-section.

Distortion and Warpage

Distortion is an irreversible change in a component's size or shape that occurs during heat treatment.

This is often caused by the relief of residual stresses imparted during prior manufacturing steps (like machining) or by non-uniform heating and cooling. Thin, long, or asymmetrical parts are particularly susceptible to warpage.

Incorrect Hardness

Achieving the correct hardness is often the primary goal, and failure here can be due to several factors.

A part that is too soft may result from an insufficient austenitizing temperature or time, or a quench that was too slow for the steel's hardenability (known as slack quenching).

Conversely, a part that is too hard and brittle is often the result of an overly aggressive quench or, more commonly, an improper or missed tempering step after hardening.

Surface-Level Defects

These defects degrade the surface of the steel, compromising its performance in applications requiring high wear resistance or fatigue strength.

Decarburization

Decarburization is the loss of carbon from the surface of the steel. This is a significant issue because carbon is the primary element responsible for hardness in steel.

It is caused by a chemical reaction between the steel and the furnace atmosphere (oxygen, carbon dioxide, water vapor) at high temperatures. The result is a soft, weak surface layer that drastically reduces wear resistance and fatigue life.

Oxidation and Scaling

Oxidation is the formation of a layer of iron oxide (scale) on the component's surface when heated in an oxygen-rich atmosphere.

This scale results in a poor surface finish and a loss of dimensional accuracy. It can also insulate the part, leading to non-uniform quenching and potentially masking more severe underlying defects like quench cracks.

Understanding the Trade-offs

Selecting a heat treatment process always involves balancing competing factors. Understanding these trade-offs is key to preventing defects.

Hardness vs. Toughness

The fundamental trade-off in heat treating is that processes which create extreme hardness, like quenching, also create a brittle microstructure (untempered martensite).

Tempering is the essential post-quenching step that reduces this brittleness and internal stress, imparting toughness. However, this process also reduces the peak hardness. The art is in finding the precise balance required for the application.

Cooling Rate vs. Internal Stress

A faster cooling rate is more effective at achieving full hardness, especially in lower-alloy steels.

However, a rapid quench (e.g., using water or brine) generates immense thermal gradients and internal stress, dramatically increasing the risk of distortion and cracking. A slower quench (e.g., using oil or gas) is gentler but may not achieve maximum hardness.

Atmosphere Control vs. Cost

Using a controlled atmosphere (like a vacuum, nitrogen, or argon) completely prevents decarburization and oxidation, yielding a clean, bright part.

These processes, however, require more sophisticated and expensive equipment compared to heating in an open-air furnace. The cost must be justified by the component's surface requirements.

How to Mitigate Heat Treatment Defects

Preventing defects requires a systematic approach focused on design, material selection, and precise process control.

- If your primary focus is preventing cracking and distortion: Design parts with generous radii and uniform cross-sections, and select a less severe quenching medium appropriate for the steel's hardenability.

- If your primary focus is maintaining surface integrity: Utilize controlled atmosphere furnaces (e.g., vacuum, inert gas) or protective coatings to prevent decarburization and scaling.

- If your primary focus is achieving consistent hardness: Ensure precise control over austenitizing temperature, soak time, and quench agitation, and always follow up with a proper tempering cycle.

Successful heat treatment is a controlled engineering process where foresight in design and precision in execution determine the final quality of the component.

Summary Table:

| Defect Type | Primary Cause | Key Consequence |

|---|---|---|

| Quench Cracking | Excessive internal stress from rapid cooling | Catastrophic part failure |

| Distortion/Warping | Non-uniform heating/cooling or residual stress | Loss of dimensional accuracy |

| Incorrect Hardness | Improper austenitizing, quenching, or tempering | Poor mechanical performance |

| Decarburization | Reaction with furnace atmosphere (O2, CO2, H2O) | Soft surface layer, reduced fatigue life |

| Oxidation/Scaling | Heating in an oxygen-rich environment | Poor surface finish, dimensional loss |

Achieve Flawless Results with KINTEK's Expert Solutions

Eliminate costly heat treatment defects and ensure your steel components meet the highest standards for hardness, durability, and dimensional accuracy. KINTEK specializes in premium lab equipment and consumables, providing the precise furnaces, atmosphere control systems, and expert support your laboratory needs to perfect its thermal processing.

We help you:

- Prevent Cracking & Distortion: With equipment designed for uniform heating and controlled cooling.

- Maintain Surface Integrity: Through reliable atmosphere-controlled and vacuum furnace solutions.

- Guarantee Consistent Hardness: With precise temperature control and monitoring tools.

Let's optimize your heat treatment process. Contact our experts today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision

- What is a vacuum furnace used for? Unlock High-Purity Heat Treatment for Superior Materials

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost