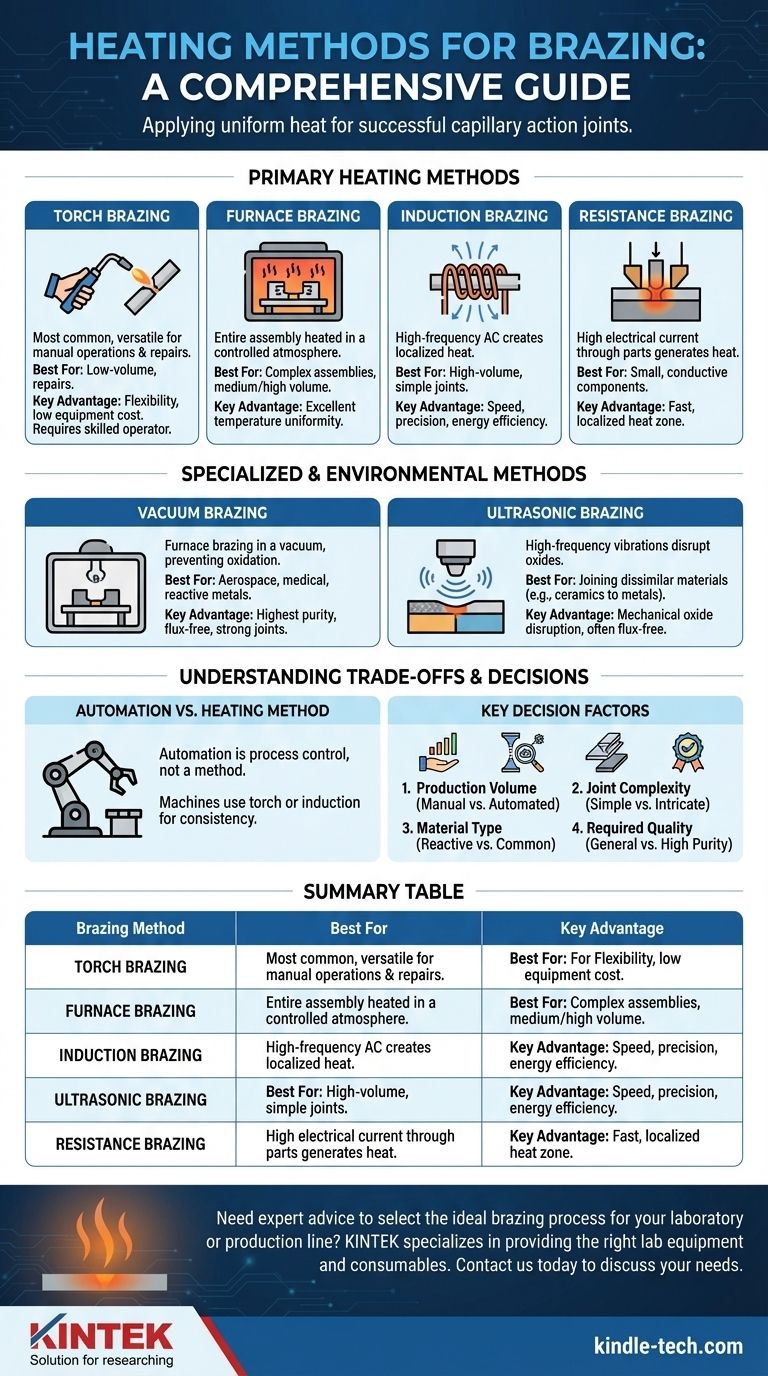

To successfully braze a joint, you must apply heat uniformly to the base metals, allowing the filler metal to be drawn into the joint by capillary action. The most common heating methods to achieve this are torch brazing, furnace brazing, induction brazing, and resistance brazing. More specialized methods like vacuum and ultrasonic brazing are used for specific, high-performance applications.

The critical insight is not simply knowing the different heating methods, but understanding that each one represents a different balance of speed, cost, precision, and production volume. The ideal method is entirely dependent on the specific requirements of your application.

The Primary Heating Methods Explained

Choosing the right heating method is the first major decision in designing a brazing process. Each technique interacts with the workpiece differently, offering distinct advantages for certain materials, joint designs, and production scales.

Torch Brazing

This is the most common and versatile method, especially for manual operations and repairs. It involves using a fuel gas flame (like oxy-acetylene or natural gas-air) to directly heat the parts.

The primary advantage of torch brazing is its flexibility and low initial equipment cost. However, it is highly dependent on operator skill to achieve uniform heating and avoid overheating, which can damage the base metals or flux.

Furnace Brazing

In this method, the entire assembly (with filler metal and flux pre-placed) is heated in a furnace with a controlled atmosphere.

This process ensures excellent temperature uniformity, making it ideal for complex assemblies or for brazing multiple joints on a single part. Because many parts can be processed at once, it is highly suited for medium to high-volume production.

Induction Brazing

Induction brazing uses a high-frequency alternating current passed through a copper coil. This creates an electromagnetic field that induces a current within the metal parts, generating rapid, localized heat.

This method is extremely fast, precise, and energy-efficient. Because the heat is localized to the joint area, it minimizes distortion and is easily automated for high-volume, repeatable manufacturing processes.

Resistance Brazing

This method passes a high electrical current through the parts, using the assembly's own electrical resistance to generate heat at the joint interface. Carbon electrodes are typically used to apply both pressure and current.

Resistance brazing is very fast and creates a localized heat zone. It is best suited for joining small, electrically conductive components where the heat can be generated precisely where it is needed.

Specialized and Environmental Methods

For applications with extreme requirements for cleanliness, material compatibility, or performance, specialized variations of these core methods are necessary.

Vacuum Brazing

Vacuum brazing is a specific type of furnace brazing performed inside a vacuum chamber. By removing the atmosphere, it prevents oxidation of the base metals entirely.

This eliminates the need for flux, resulting in exceptionally clean and high-strength joints. It is the standard for mission-critical components in the aerospace, medical, and semiconductor industries, especially for reactive materials like titanium and aluminum.

Ultrasonic Brazing

This is a niche method used primarily for joining dissimilar materials, such as ceramics to metals. It uses high-frequency ultrasonic vibrations to facilitate the wetting of the filler metal onto the surfaces.

The key advantage is its ability to disrupt surface oxides mechanically, which often allows for brazing without the use of chemical flux.

Understanding the Trade-offs

The terms used to describe brazing equipment can be confusing. It's crucial to distinguish between a heating method and an automation strategy.

Automation vs. Heating Method

The term "Automatic Brazing Machine" does not describe a heating method. It describes a level of process control.

An automatic machine can utilize various heat sources, most commonly torch flames or induction coils, to perform the brazing process with minimal human intervention. The goal is to improve consistency, repeatability, and throughput.

Key Decision Factors

Your choice of heating method should be driven by four main considerations:

- Production Volume: A manual torch is fine for repairs, but induction or furnace methods are required for thousands of parts.

- Joint Complexity: A furnace provides the uniform heat needed for intricate parts, whereas a torch is better for a single, simple joint.

- Material Type: Reactive metals like titanium demand a vacuum furnace, while common steels are forgiving with most methods.

- Required Quality: Aerospace and medical joints require the flux-free purity of vacuum brazing, while general plumbing does not.

Making the Right Choice for Your Goal

Ultimately, the goal is to select the process that delivers the required joint quality at the lowest total cost. Use these guidelines to narrow your options.

- If your primary focus is low-volume production or repairs: Torch brazing offers the best combination of low capital cost and flexibility.

- If your primary focus is high-volume, repeatable manufacturing of simple joints: Induction brazing delivers unmatched speed, precision, and consistency.

- If your primary focus is joining complex assemblies or many parts at once: Furnace brazing provides the most uniform heating for intricate geometries.

- If your primary focus is achieving the highest purity and strength with reactive metals: Vacuum brazing is the definitive method for mission-critical applications.

By matching the heating method to your specific material, volume, and quality requirements, you ensure a strong, reliable, and cost-effective brazed joint.

Summary Table:

| Brazing Method | Best For | Key Advantage |

|---|---|---|

| Torch Brazing | Repairs, low-volume work | Flexibility & low equipment cost |

| Furnace Brazing | Complex parts, medium/high volume | Excellent temperature uniformity |

| Induction Brazing | High-volume, simple joints | Speed, precision, & energy efficiency |

| Resistance Brazing | Small, conductive parts | Fast & localized heat |

| Vacuum Brazing | Aerospace, medical, reactive metals | Highest purity, flux-free joints |

Need expert advice to select the ideal brazing process for your laboratory or production line? KINTEK specializes in providing the right lab equipment and consumables to support your brazing applications, from research and development to full-scale manufacturing. Our team can help you achieve strong, reliable, and cost-effective joints. Contact us today to discuss your specific needs and how we can support your success.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the safety precautions for molten metal? A Complete Guide to PPE, Environment, and Procedures

- How is temperature controlled within a vacuum induction melting furnace? Mastering Precision for Advanced Alloys

- What is the primary function of a vacuum induction furnace? Optimize FeCrAl Alloy Smelting with High Purity

- What is the primary purpose of using a vacuum induction furnace for AFA steel? Ensure Alloy Integrity & Purity

- What are the advantages of induction equipment? Achieve Faster, Cleaner, and More Precise Heating

- What is an induction furnace for heat treatment? Achieve Unmatched Speed and Precision in Metal Processing

- Does copper heat up in induction? The Surprising Truth About Heating Non-Ferrous Metals

- How can the service life of an induction furnace lining be improved at the furnace mouth? Expert Maintenance Tips