The two primary types of Cold Isostatic Pressing (CIP) are the wet-bag method and the dry-bag method. Both processes use a liquid medium to apply uniform, isostatic pressure to compact powdered material into a solid "green" part at ambient temperature. The key distinction lies in how the tooling (the flexible mold holding the powder) interacts with the pressure-transmitting fluid.

The choice between wet-bag and dry-bag CIP is not about which is "better," but which is appropriate for your goal. Wet-bag offers maximum flexibility for complex, low-volume parts, while dry-bag delivers speed and automation for high-volume production.

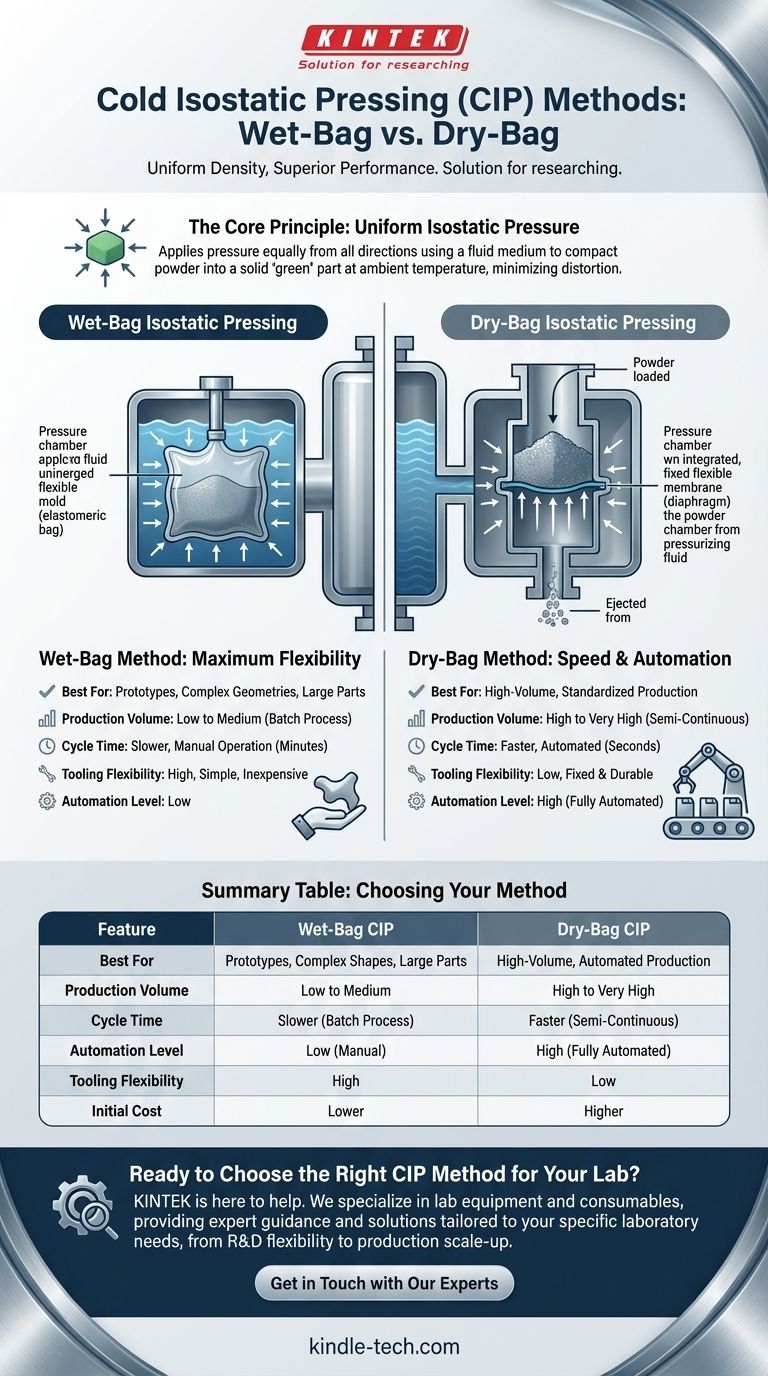

The Core Principle of Cold Isostatic Pressing

Cold Isostatic Pressing is a material processing method that consolidates powders into a solid mass before final heat treatment (sintering). It is distinct from conventional uniaxial pressing, which applies force from only one or two directions.

Why Use Isostatic Pressure?

By using a fluid to apply pressure equally from all directions, CIP overcomes many limitations of traditional pressing. This isostatic pressure ensures the resulting compact, known as a green part, has a highly uniform density.

This uniformity minimizes warping and distortion during the final sintering stage, resulting in a stronger, more reliable finished component.

The Two Methods: Wet-Bag vs. Dry-Bag

The fundamental difference between the two CIP methods is whether the flexible mold containing the powder is immersed directly in the pressurizing fluid or is isolated from it.

Wet-Bag Isostatic Pressing

In the wet-bag method, the powder is first sealed in a flexible, elastomeric mold. This entire sealed mold is then submerged in the fluid within a high-pressure vessel.

Because the mold is physically "wet" by the surrounding fluid, this process is highly versatile. It is the go-to method for prototypes, complex geometries, and very large components.

Dry-Bag Isostatic Pressing

In the dry-bag method, the flexible mold is an integral, permanent part of the pressure vessel itself. It acts as a membrane, isolating the powder from the pressurizing fluid.

Operators simply load powder into the top of this built-in mold, the cycle runs automatically, and the compacted part is ejected. This method is much faster and lends itself to full automation, making it ideal for mass production.

Understanding the Trade-offs: Process Selection Criteria

Choosing the correct method requires a clear understanding of your production goals, as each approach presents a different set of advantages and limitations.

Production Volume

This is the most critical factor. Wet-bag is a batch process with longer cycle times, making it suitable for research, development, and low-volume production.

Dry-bag is a semi-continuous or fully automated process designed for high throughput. It is the clear choice for mass manufacturing thousands or millions of identical parts per year.

Part Complexity and Size

The wet-bag method offers near-limitless flexibility in part size and shape. Since the tooling is independent of the pressure vessel, it can accommodate large and intricate designs.

Dry-bag tooling is fixed within the press, limiting the geometry and size of the parts that can be produced. It is best for relatively simple, cylindrical, or tubular shapes.

Cycle Time and Automation

A typical wet-bag cycle is manual and can take several minutes to load, pressurize, and unload.

A dry-bag press can complete a cycle in a matter of seconds and is easily integrated into automated production lines, significantly reducing labor costs.

Tooling and Initial Cost

Wet-bag tooling is relatively simple and inexpensive to produce, which is ideal when iterating on designs or for short production runs.

Dry-bag systems require more complex and durable integrated tooling, representing a higher initial capital investment. However, this cost is quickly offset by a much lower per-part cost in high-volume scenarios.

Choosing the Right CIP Method for Your Application

Your choice should be dictated entirely by your manufacturing objectives, balancing flexibility against speed and volume.

- If your primary focus is R&D, prototyping, or producing complex, low-volume parts: Wet-bag pressing offers the necessary design flexibility and lower initial tooling cost.

- If your primary focus is high-volume, automated production of standardized parts: Dry-bag pressing provides the speed, repeatability, and efficiency required for mass manufacturing.

Ultimately, selecting the correct CIP method is the first step toward achieving a uniform, high-density green part that meets your specific production goals.

Summary Table:

| Feature | Wet-Bag CIP | Dry-Bag CIP |

|---|---|---|

| Best For | Prototypes, Complex Shapes, Large Parts | High-Volume, Automated Production |

| Production Volume | Low to Medium | High to Very High |

| Cycle Time | Slower (Batch Process) | Faster (Semi-Continuous) |

| Automation Level | Low (Manual) | High (Fully Automated) |

| Tooling Flexibility | High | Low |

| Initial Cost | Lower | Higher |

Ready to Choose the Right CIP Method for Your Lab?

Selecting between wet-bag and dry-bag Cold Isostatic Pressing is critical for achieving uniform density and optimal performance in your final components. The right equipment directly impacts your production efficiency, part quality, and bottom line.

KINTEK is here to help. We specialize in lab equipment and consumables, providing expert guidance and solutions tailored to your specific laboratory needs. Whether you're in R&D requiring the flexibility of wet-bag CIP or scaling up production with dry-bag automation, we have the expertise to support your success.

Contact us today to discuss your project and discover how our CIP solutions can enhance your manufacturing process.

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Vacuum Cold Mounting Machine for Sample Preparation

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the use of cold isostatic pressing? Achieve Uniform Density for Superior Parts

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What are the advantages of isostatic compaction? Achieve Uniform Density and Complex Shapes

- How does a cold isostatic press (CIP) address YAG ceramic density? Achieve Uniform High-Density Green Bodies

- What is the function of a Cold Isostatic Press (CIP) in the fabrication of pouch-type all-solid-state batteries?

- What is cold isostatic pressure? Achieve Uniform Density for Complex Powder Parts

- What is the difference between isostatic pressing and uniaxial pressing? Choosing the Right Powder Compaction Method

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction