When considering a filter press for liquid-solid separation, it's crucial to know that they are not a single technology but a family of designs, each optimized for different needs. The main types are categorized by their plate design: the traditional plate and frame, the common recessed chamber, and the high-efficiency membrane filter press. The choice among them depends entirely on your required cake dryness, operational scale, and budget.

The core decision is not just about identifying different types, but about understanding the fundamental trade-off: higher initial equipment cost for a membrane press often yields significant long-term savings through drier solids, reduced disposal fees, and shorter processing cycles.

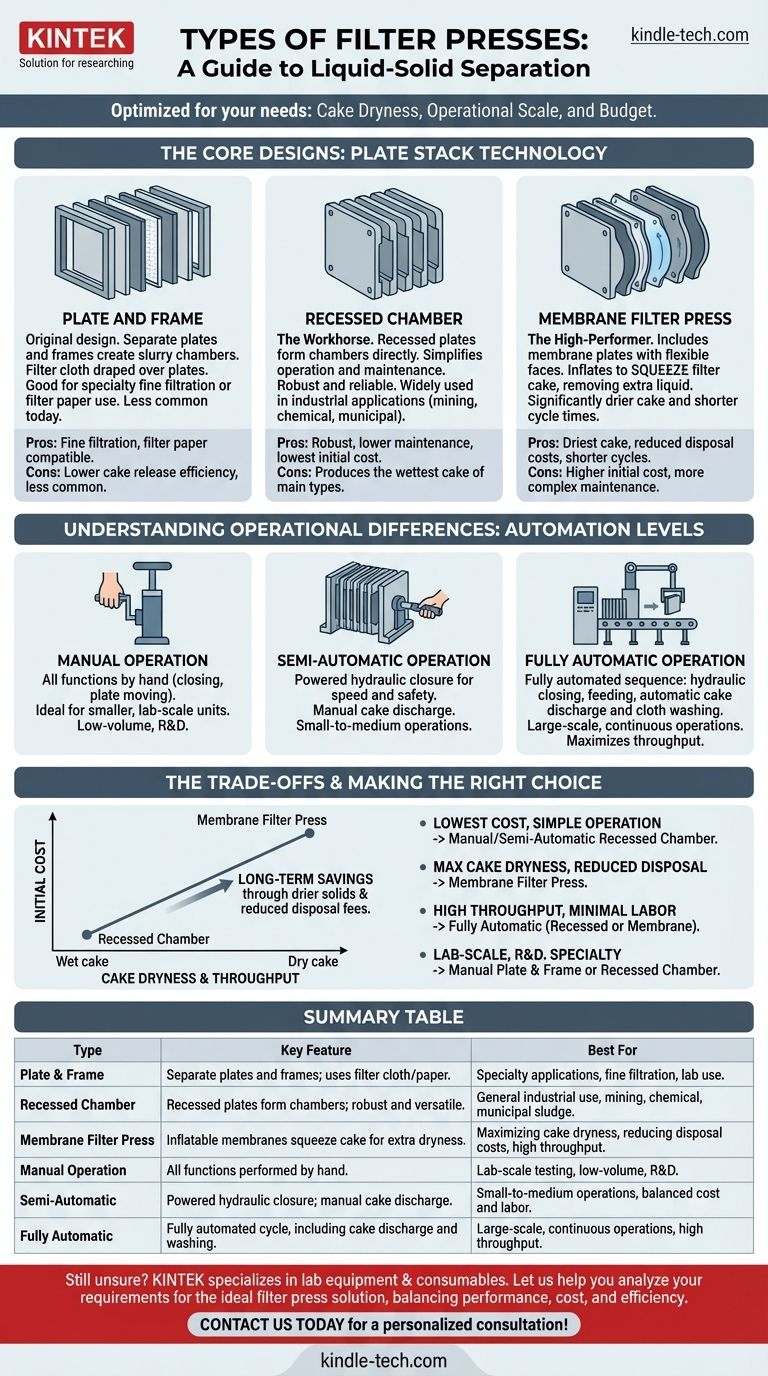

The Core Filter Press Designs

The "stack" of plates is the heart of any filter press. The design of these plates dictates the machine's performance, capabilities, and ideal application.

The Classic: Plate and Frame

The plate and frame press is the original design. It consists of a series of flat, solid "plates" alternating with hollow "frames" that create the chamber for the slurry.

Filter cloths are draped over the plates, and when the stack is compressed, the slurry fills the frames. The liquid passes through the cloth, and the solid cake builds up inside the frame.

This design is less common today but is still used for applications requiring filter paper in addition to cloth, or for very fine filtration where cake release is not the primary concern.

The Workhorse: Recessed Chamber

This is the most widely used and versatile type of filter press. Each plate has a recess on both sides, typically 15-20 mm deep.

When two recessed plates are pressed together, their recesses form a single, enclosed chamber for the solid cake to form. This eliminates the need for separate frames, simplifying operation and maintenance.

Recessed chamber presses are robust, reliable, and suitable for a vast range of industrial applications, from mining and chemical manufacturing to municipal sludge dewatering.

The High-Performer: Membrane Filter Press

A membrane press looks similar to a recessed chamber press but includes a mix of standard recessed plates and special "membrane" plates. These membrane plates have a flexible, impermeable face made of rubber or thermoplastic.

After the initial filtration cycle fills the chambers, the membrane is inflated with water or air. This squeezes the filter cake, physically forcing out additional liquid.

This "squeeze" phase results in a significantly drier filter cake and can dramatically reduce the overall cycle time compared to a standard recessed chamber press.

Understanding Operational Differences

Beyond the plate design, filter presses are also classified by their level of automation. This directly impacts labor requirements, throughput, and suitability for different operational scales.

Manual Operation

On smaller, often laboratory-scale units, all functions are performed by hand. This includes closing the press with a manual hydraulic pump or screw mechanism and physically moving each plate to discharge the filter cake.

As noted in pilot studies, these are often built from stainless steel for durability and are ideal for low-volume testing.

Semi-Automatic Operation

This is a common configuration for small-to-medium-sized operations. The press features a powered hydraulic system for opening and closing the plate stack, which is much faster and safer than a manual closure.

However, the operator must still manually separate each plate to allow the discharged cakes to fall.

Fully Automatic Operation

In large-scale or continuous operations, fully automatic systems are standard. These systems automate the entire sequence: hydraulic closing, slurry feeding, cake discharge via a mechanical plate shifter, and even high-pressure filter cloth washing.

This level of automation minimizes labor, ensures consistent cycle times, and maximizes the plant's overall throughput.

Understanding the Trade-offs

Choosing the right filter press requires an objective look at the compromises between performance and cost. Your "best" option is the one that best aligns with your operational and financial realities.

Cake Dryness vs. Initial Cost

A recessed chamber press offers the lowest initial capital cost. However, it produces the wettest cake of the three main types.

A membrane filter press has a higher upfront cost due to the more complex plates and inflation system. Its benefit is producing the driest cake, which can drastically lower hauling and disposal costs or increase the value of a recovered product.

Cycle Time and Throughput

Recessed chamber presses operate on a fixed cycle time determined by how long it takes to pump slurry until the chambers are full.

Membrane presses can significantly shorten this cycle. Because the squeeze phase removes so much additional water, the initial feed cycle can be stopped much earlier, increasing the number of cycles possible per day.

Maintenance and Complexity

Simpler is often more reliable. The robust design of a recessed chamber press means fewer moving parts and lower maintenance costs over the life of the machine.

Membrane presses, while highly efficient, introduce more complexity. The membranes are wearing parts that will eventually need replacement, and the inflation system adds another layer of maintenance.

Making the Right Choice for Your Goal

Your optimal choice depends entirely on your operational priorities. Balancing initial investment against long-term operational costs is key to making a sound decision.

- If your primary focus is lowest capital cost and simple operation: A manual or semi-automatic recessed chamber press is the most direct and cost-effective solution.

- If your primary focus is maximizing cake dryness and reducing disposal costs: The higher investment in a membrane filter press will almost certainly provide the best long-term return.

- If your primary focus is high throughput and minimal labor: A fully automatic filter press, either recessed or membrane, is essential for any large-scale, continuous operation.

- If your primary focus is lab-scale testing or specialty filtration: A small, manual plate and frame or recessed chamber press offers the necessary control and material compatibility for R&D.

By understanding these core designs and their operational trade-offs, you can confidently select the technology that aligns perfectly with your specific dewatering objective.

Summary Table:

| Type | Key Feature | Best For |

|---|---|---|

| Plate and Frame | Separate plates and frames; uses filter cloth/paper | Specialty applications, fine filtration, lab use |

| Recessed Chamber | Recessed plates form chambers; robust and versatile | General industrial use, mining, chemical, municipal sludge |

| Membrane Filter Press | Inflatable membranes squeeze cake for extra dryness | Maximizing cake dryness, reducing disposal costs, high throughput |

| Manual Operation | All functions performed by hand | Lab-scale testing, low-volume, R&D |

| Semi-Automatic | Powered hydraulic closure; manual cake discharge | Small-to-medium operations, balanced cost and labor |

| Fully Automatic | Fully automated cycle, including cake discharge and washing | Large-scale, continuous operations, high throughput |

Still unsure which filter press is right for your operation? The team at KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and expertise. We can help you analyze your specific requirements—whether it's for R&D, pilot testing, or full-scale production—to recommend the ideal filter press solution that balances performance, cost, and efficiency.

Contact us today for a personalized consultation and let KINTEK enhance your liquid-solid separation process!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy