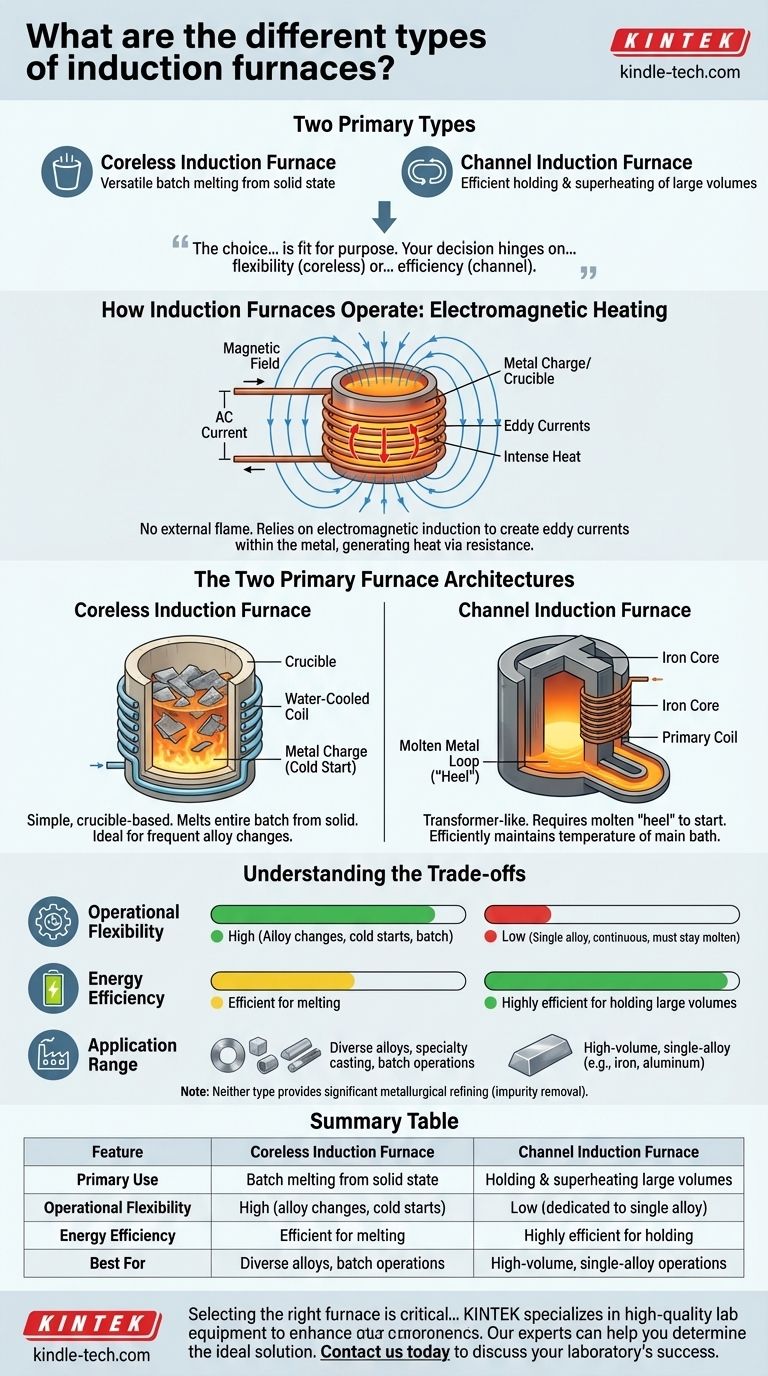

In short, there are two primary types of induction furnaces: the coreless induction furnace and the channel induction furnace. The coreless type uses a simple crucible to hold the metal charge, making it highly versatile for melting various materials from a solid state. The channel type, in contrast, maintains a continuous loop of molten metal, making it exceptionally efficient for holding large volumes at a specific temperature.

The choice between a coreless and a channel furnace is not about which is superior, but which is fit for purpose. Your decision hinges on whether you need the flexibility of batch melting diverse alloys (coreless) or the high efficiency of holding a large, continuous volume of a single metal (channel).

How Induction Furnaces Operate

The Core Principle: Electromagnetic Heating

An induction furnace does not use any external heating element or flame. Instead, it relies on the principle of electromagnetic induction.

A high-frequency alternating current is passed through a copper coil. This creates a powerful and rapidly changing magnetic field around the metal to be heated, which is known as the charge.

This magnetic field induces powerful electrical currents, called eddy currents, directly within the metal charge itself. The metal's natural resistance to the flow of these currents generates intense heat, causing it to melt quickly and efficiently.

The Two Primary Furnace Architectures

The fundamental difference between induction furnace types lies in how the coil and metal charge are configured.

The Coreless Induction Furnace

The coreless design is the most conceptually simple and widely used type for melting.

It consists of a refractory-lined crucible that contains the metal charge. This crucible is surrounded by a water-cooled copper coil. When energized, the entire mass of metal inside the crucible is heated and melted.

Because it melts the entire batch from a solid (or "cold") start, it is ideal for foundries that require frequent changes in alloys or need to operate on a non-continuous, batch-by-batch basis.

The Channel Induction Furnace

A channel furnace operates more like a transformer. It has an iron core with a primary coil, but the secondary "winding" is a closed loop or "channel" of molten metal.

This furnace cannot be started with solid metal. It requires an initial charge of molten metal, known as a "heel," to complete the circuit. The induction field then efficiently heats this loop, which circulates and keeps the main bath of metal at the desired temperature.

This makes the channel furnace function more like an extremely efficient holding and superheating unit rather than a primary melter.

Understanding the Trade-offs

Neither design is universally better; they are engineered for different operational needs and present distinct trade-offs.

Operational Flexibility

A coreless furnace offers maximum flexibility. You can melt different metals and alloys back-to-back and can shut the furnace down completely between shifts.

A channel furnace is highly inflexible. It is dedicated to a single alloy type and must remain energized to keep its molten heel from solidifying, which would damage the furnace.

Energy Efficiency

For holding large volumes of molten metal at a specific temperature, the channel furnace is significantly more energy-efficient due to its design.

For melting solid scrap or ingots from a cold start, the coreless furnace is the more effective and direct solution. It is, however, less efficient than a channel furnace for simply holding metal at temperature for long periods.

Application Range

The versatility of the coreless furnace makes it suitable for a vast range of applications, from producing high-quality steel and specialty alloys to investment casting and non-ferrous metals.

The channel furnace excels in high-volume, single-alloy applications, such as holding molten iron in large foundries or in the aluminum industry for melting and holding.

Refining Capability

It is critical to understand that neither furnace type provides significant metallurgical refining. Their primary purpose is to melt and maintain the temperature and homogeneity of an alloy with minimal loss, not to remove impurities like sulfur or phosphorus.

Making the Right Choice for Your Operation

To select the correct furnace, you must first define your primary operational goal.

- If your primary focus is operational flexibility and batch melting: A coreless induction furnace is the definitive choice for its ability to handle various alloys and cold starts.

- If your primary focus is high-volume holding and energy efficiency: A channel induction furnace excels at maintaining large quantities of a single molten metal at a consistent temperature with lower energy costs.

- If your primary focus is diverse alloy manufacturing: The batch-oriented nature of the coreless furnace is essential for producing a portfolio of different metal chemistries without cross-contamination.

Understanding these fundamental design differences empowers you to select the precise tool for your specific metallurgical goal.

Summary Table:

| Feature | Coreless Induction Furnace | Channel Induction Furnace |

|---|---|---|

| Primary Use | Batch melting from solid state | Holding & superheating large volumes |

| Operational Flexibility | High (alloy changes, cold starts) | Low (dedicated to single alloy) |

| Energy Efficiency | Efficient for melting | Highly efficient for holding |

| Best For | Diverse alloys, batch operations | High-volume, single-alloy operations |

Selecting the right furnace is critical to your lab's productivity and efficiency. KINTEK specializes in providing high-quality lab equipment, including induction furnaces tailored to your specific melting and holding requirements. Our experts can help you determine the ideal solution—whether you need the flexibility of a coreless furnace or the efficiency of a channel furnace. Contact us today via our [#ContactForm] to discuss how we can support your laboratory's success with the perfect equipment.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting