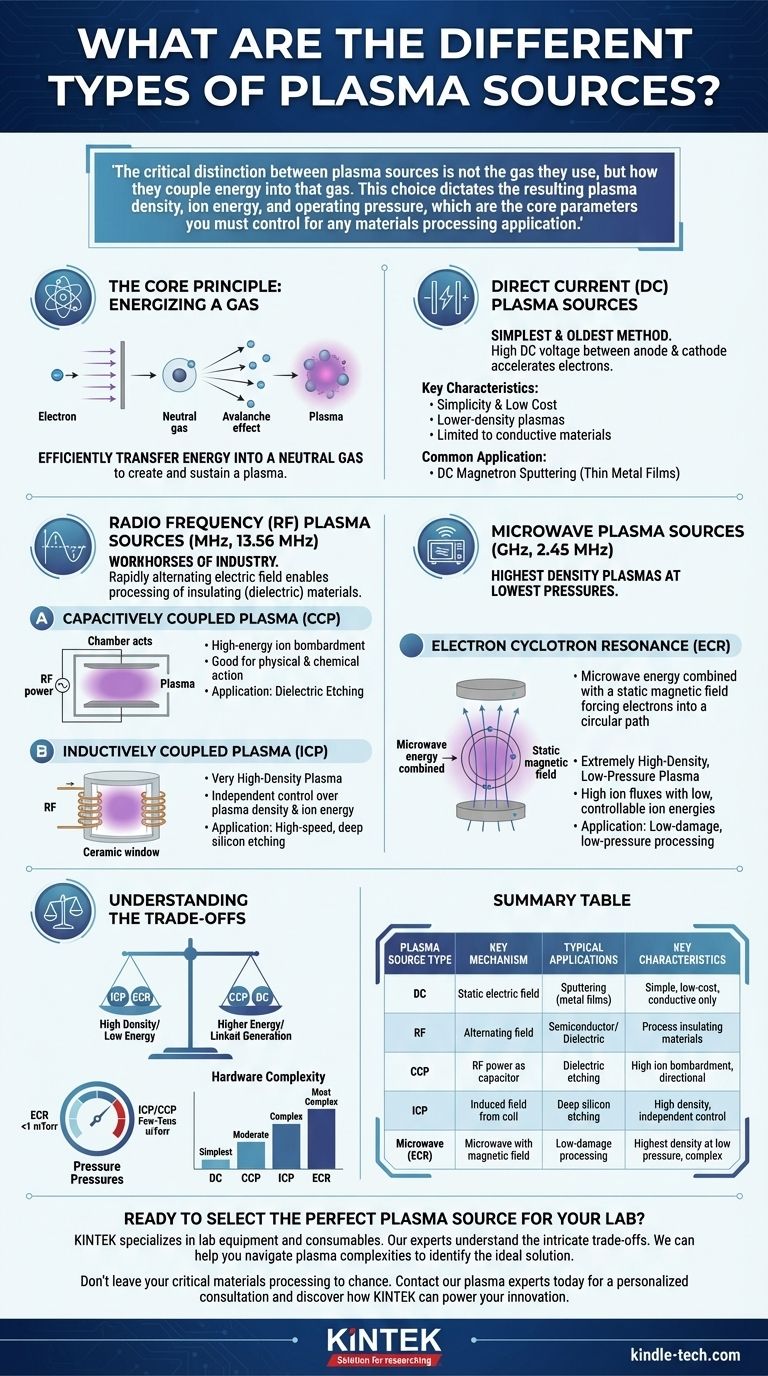

The primary types of plasma sources are categorized by the frequency of the electromagnetic field used to energize a gas. The most common industrial sources are Direct Current (DC), Radio Frequency (RF)—which includes Capacitively Coupled Plasma (CCP) and Inductively Coupled Plasma (ICP)—and Microwave sources, such as Electron Cyclotron Resonance (ECR). Each method offers a fundamentally different way to control plasma properties for specific applications.

The critical distinction between plasma sources is not the gas they use, but how they couple energy into that gas. This choice dictates the resulting plasma density, ion energy, and operating pressure, which are the core parameters you must control for any materials processing application.

The Core Principle: Energizing a Gas

Every plasma source is designed to solve one problem: how to efficiently transfer energy into a neutral gas to create and sustain a plasma. This process involves stripping electrons from gas atoms, creating a mixture of ions, electrons, and neutral particles.

The Role of Electrons

The process begins by accelerating free electrons with an electric field. These energized electrons collide with neutral gas atoms, knocking loose other electrons in an avalanche effect that ignites and sustains the plasma.

How Energy is Coupled

The "type" of plasma source is defined by the nature of the electromagnetic field used to accelerate these electrons. The frequency of this field—from DC (0 Hz) to RF (MHz) to Microwaves (GHz)—is the most important design parameter.

Direct Current (DC) Plasma Sources

DC plasma is the simplest and oldest method of plasma generation. It functions much like a fluorescent light tube, but with different gases and power levels.

How DC Discharges Work

A high DC voltage is applied between two electrodes (an anode and a cathode) inside a vacuum chamber. This static electric field accelerates electrons, which then ionize the gas through collisions.

Key Characteristics

DC sources are known for their simplicity and low cost. However, they typically produce lower-density plasmas and can only be used with conductive target materials, as charge buildup on insulating materials will extinguish the plasma.

Common Applications

The most common application is DC magnetron sputtering, used to deposit thin metal films. The high-energy ion bombardment characteristic of DC discharges makes it ideal for this physical process.

Radio Frequency (RF) Plasma Sources

RF sources are the workhorses of the semiconductor and materials processing industries. They operate in the megahertz (MHz) frequency range, most commonly at 13.56 MHz.

Why Use RF?

The rapidly alternating electric field allows for the processing of insulating (dielectric) materials. The quick oscillation prevents a net charge from building up on surfaces, which would otherwise stop the plasma process.

Capacitively Coupled Plasma (CCP)

In a CCP system, the chamber itself acts as a capacitor. The RF power is applied to one electrode, and the chamber walls are typically grounded. The plasma is generated in the space between these two "plates."

This design creates strong electric fields in the plasma sheaths near the electrodes. This results in relatively high-energy ion bombardment on the substrate surface, making CCPs excellent for processes that require physical and chemical action, like dielectric etching.

Inductively Coupled Plasma (ICP)

An ICP source uses a coil, typically wrapped around a ceramic window on the top of the chamber. RF power applied to the coil creates a time-varying magnetic field, which in turn induces a powerful electric field within the plasma itself.

This method is highly efficient at generating a very high-density plasma. Critically, this can be done without creating a high voltage sheath, allowing for independent control over plasma density (via the ICP coil) and ion energy (via a separate RF bias on the substrate). ICP is the standard for high-speed, deep silicon etching.

Microwave Plasma Sources

Operating in the gigahertz (GHz) range, typically at 2.45 GHz, microwave sources can create the highest density plasmas at the lowest operating pressures.

Electron Cyclotron Resonance (ECR)

ECR sources use a combination of microwave energy and a strong static magnetic field. The magnetic field forces electrons into a circular path, and the microwave frequency is tuned to match this "cyclotron" frequency.

This resonance condition allows for incredibly efficient energy transfer to the electrons, generating an extremely high-density, low-pressure plasma.

Key Characteristics

ECR systems produce high ion fluxes with very low, controllable ion energies. However, the hardware, involving microwave generators and large electromagnets, is significantly more complex and expensive than RF or DC systems.

Understanding the Trade-offs

Choosing a plasma source is a matter of balancing competing requirements. There is no single "best" source; there is only the best source for a specific technical goal.

Plasma Density vs. Ion Energy

This is the most critical trade-off.

- ICP and ECR are masters of high plasma density with low ion energy. They decouple density generation from the energy of ions hitting the surface.

- CCP and DC inherently link plasma generation with higher ion energy at the substrate surface.

Operating Pressure

The ability to sustain a plasma varies with pressure.

- ECR sources excel at very low pressures (<1 mTorr), where collisions are infrequent.

- ICP and CCP operate in the low-to-medium pressure range (a few to tens of mTorr).

- DC discharges often require slightly higher pressures to sustain the discharge.

Hardware Complexity and Cost

Simplicity is a major engineering constraint.

- DC sources are the simplest and most cost-effective.

- CCP systems are moderately complex.

- ICP systems add the complexity of an inductive coil and matching network.

- ECR systems are the most complex and expensive due to microwave hardware and large magnets.

Selecting the Right Source for Your Application

Your process requirements directly map to a specific plasma source technology.

- If your primary focus is high-rate chemical etching or deposition: You need a high-density source like an ICP or ECR to provide the highest possible flux of reactive species.

- If your primary focus is physical sputtering of a metal target: A DC magnetron source provides the high-energy ion bombardment needed to physically eject material from the target.

- If your primary focus is etching dielectric materials with directionality: A CCP provides a desirable combination of chemical reactants and moderate-to-high ion energy to ensure an anisotropic etch.

- If your primary focus is low-damage processing at very low pressures: An ECR source offers unparalleled control and plasma density in the low-pressure regime.

By understanding how each source couples energy into a gas, you can confidently select the precise plasma tool for your material processing challenge.

Summary Table:

| Plasma Source Type | Key Mechanism | Typical Applications | Key Characteristics |

|---|---|---|---|

| Direct Current (DC) | Static electric field between two electrodes | DC Magnetron Sputtering (metal films) | Simple, low-cost, high ion energy, limited to conductive materials |

| Radio Frequency (RF) | Alternating electric field (MHz range) | Semiconductor processing, dielectric etching | Can process insulating materials, common standard (13.56 MHz) |

| Capacitively Coupled (CCP) | RF power applied to electrode, chamber as capacitor | Dielectric etching (anisotropic) | High ion bombardment, good for directional processes |

| Inductively Coupled (ICP) | Induced electric field from RF coil | High-speed, deep silicon etching | High-density plasma, independent control of density and ion energy |

| Microwave (e.g., ECR) | Microwave energy with static magnetic field (GHz) | Low-damage, low-pressure processing | Highest density plasma at low pressure, complex and expensive |

Ready to Select the Perfect Plasma Source for Your Lab?

Choosing the right plasma technology is critical for your research or production process. The wrong source can lead to inefficiency, material damage, or failed experiments.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts understand the intricate trade-offs between DC, RF, and Microwave plasma sources. We can help you navigate the complexities of plasma density, ion energy, and operating pressure to identify the ideal solution for your specific application—whether it's thin-film deposition, precise etching, or surface modification.

We provide:

- Expert Guidance: Leverage our deep technical knowledge to match the plasma source to your exact technical requirements and budget.

- Reliable Equipment: Source high-performance plasma systems from leading manufacturers, ensuring reproducibility and precision in your work.

- Ongoing Support: From installation to maintenance and consumables, we are your partner in ensuring your plasma processes run smoothly and successfully.

Don't leave your critical materials processing to chance. Contact our plasma experts today for a personalized consultation and discover how KINTEK can power your innovation.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Spark Plasma Sintering Furnace SPS Furnace

- Electrolytic Electrochemical Cell for Coating Evaluation

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition